A kind of preparation method of ethylene-undecenyl alcohol copolymer and ultrahigh molecular weight polyethylene mixture

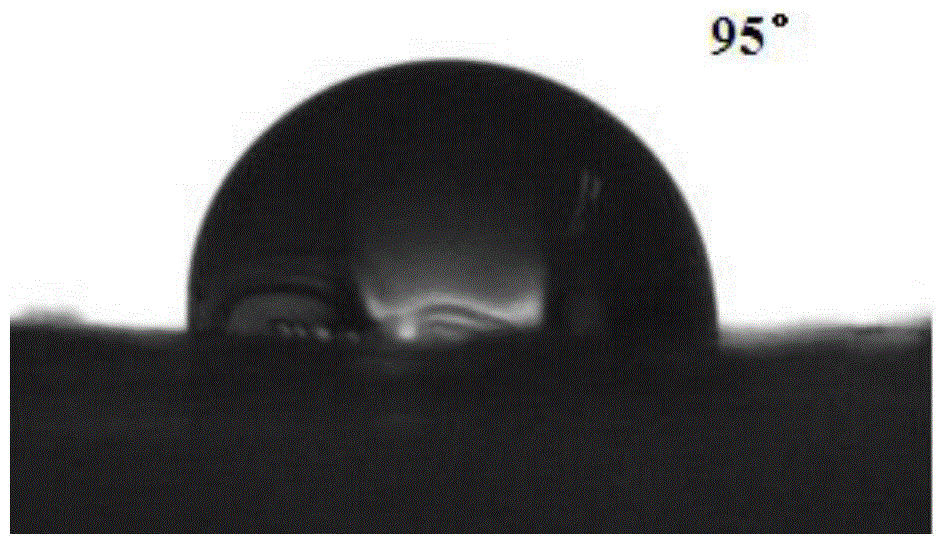

A technology of ultra-high molecular weight and polyethylene, which is applied in the field of olefin polymerization reaction technology, can solve the problems of product molecular weight decrease, accelerate the chain transfer process of ethylene homopolymerization catalyst, and reduce the polymerization activity of catalyst, so as to achieve the improvement of hydrophilicity and processability , low entanglement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

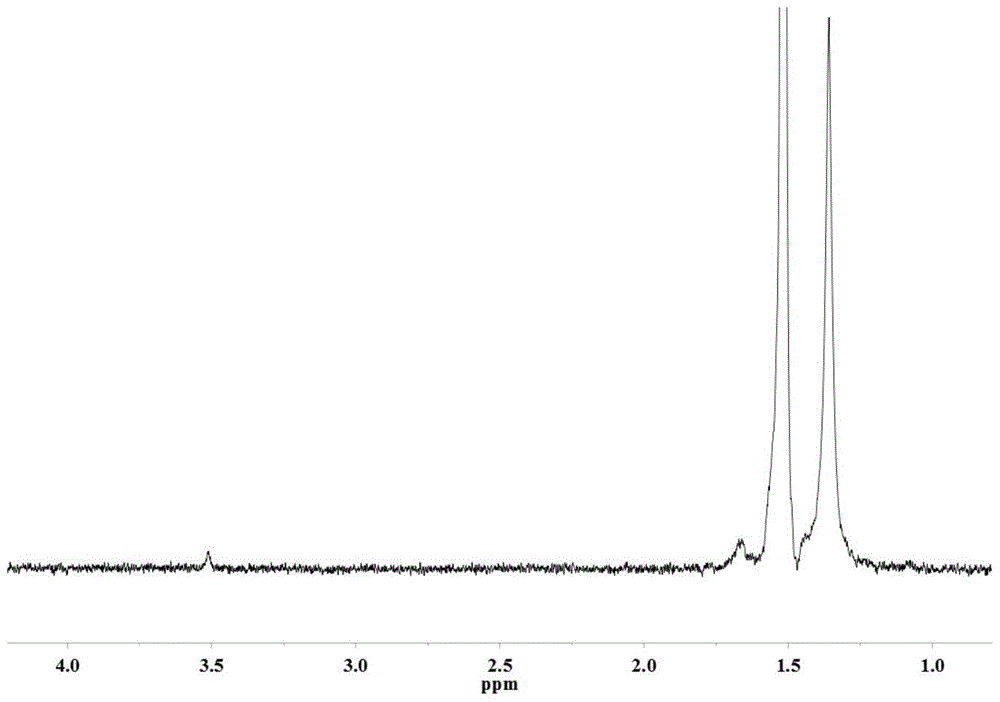

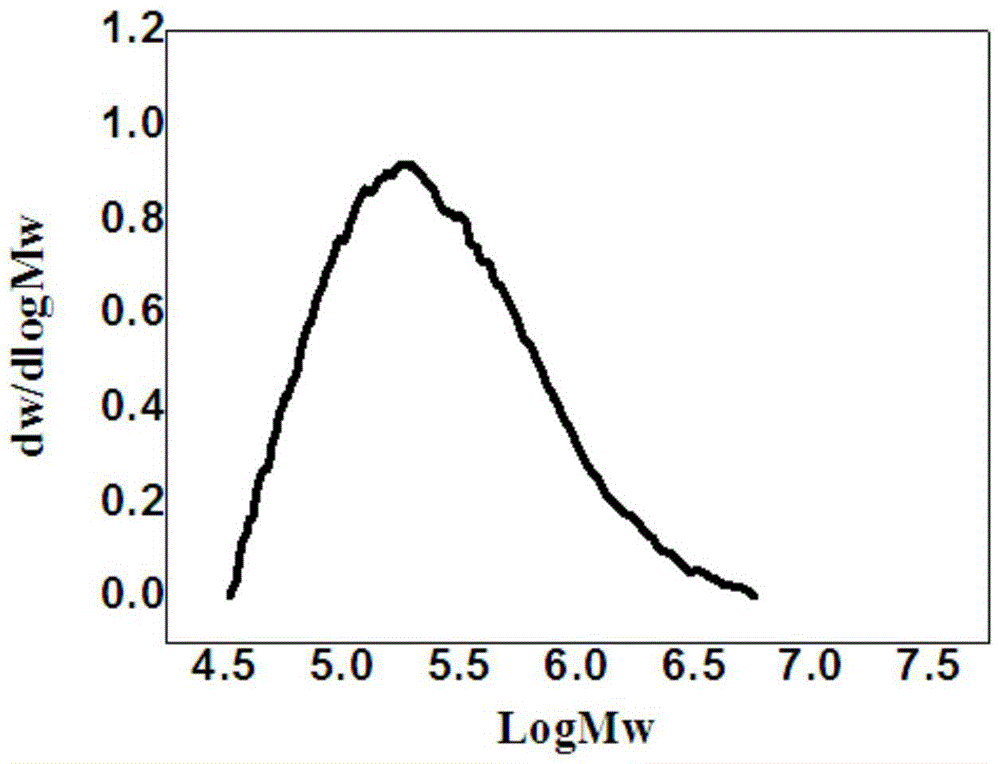

[0048] The preparation method of ultra-high molecular weight polyethylene and poly(ethylene-undecenyl alcohol) has the following steps:

[0049] VCl 3 The catalyst is weighed according to the weight ratio of V atoms to the silica carrier of 1 wt%, and then added to the toluene solution and stirred for 1 hour to obtain solid particles; the solid particles are washed 5 times with toluene solution, and then the solid particles are dried to a free-flowing state to obtain the catalyst a. Polystyrene is weighed according to polystyrene accounting for 30% of the weight of silicon dioxide, dissolved in toluene, prepared into a homogeneous polymer solution and mixed with the above-mentioned catalyst A to obtain a mixed solution; introduce steam form into the mixed solution n-hexane, so that polystyrene is deposited on the catalyst A, and the introduction rate of n-hexane is 1ml / min; after the catalyst A deposited by the polymer is washed 3 times in n-hexane, it is dried to a free-flow...

Embodiment 2

[0054] VCl 3 The catalyst is weighed according to the weight ratio of V atoms to the silica carrier 5wt%, and then added to the toluene solution and stirred for 1 hour to obtain solid particles; the solid particles are washed 5 times with toluene solution, and then the solid particles are dried to a free-flowing state to obtain the catalyst a. Polystyrene is weighed according to polystyrene accounting for 100% of the weight of silicon dioxide, dissolved in toluene, prepared into a homogeneous polymer solution and mixed with the above-mentioned catalyst A to obtain a mixed solution; introduce steam form into the mixed solution n-hexane, so that polystyrene is deposited on the catalyst A, and the introduction rate of n-hexane is 10ml / min; after the catalyst A deposited by the polymer is washed 3 times in n-hexane, it is dried to a free-flowing state to obtain catalyst B; Weigh iron acetylacetonate according to the weight ratio of 0.5wt% of metal atom in acetylacetonate compound...

Embodiment 3

[0058] The preparation method of embodiment 3 ultra-high molecular weight polyethylene and poly(ethylene-undecenyl alcohol), has the following steps:

[0059] VCl 3 The catalyst was weighed according to 0.1wt% of the weight ratio of V atoms to the silica carrier, and then added to the toluene solution and stirred for 1 hour to obtain solid particles; the solid particles were washed 5 times with toluene solution, and then the solid particles were dried to a free-flowing state to obtain Catalyst A. Polystyrene is weighed according to polystyrene accounting for 5% of the weight of silicon dioxide, dissolved in toluene, prepared into a homogeneous polymer solution and mixed with the above-mentioned catalyst A to obtain a mixed solution; introduce steam form into the mixed solution n-hexane, so that polystyrene is deposited on the catalyst A, and the introduction rate of n-hexane is 0.05ml / min; after the catalyst A deposited by the polymer is washed 3 times in n-hexane, it is drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com