Luminous safety hub and manufacturing method for same

A manufacturing method and hub technology, applied in luminous coatings, coatings, epoxy resin coatings, etc., to achieve the effect of improving driving safety and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

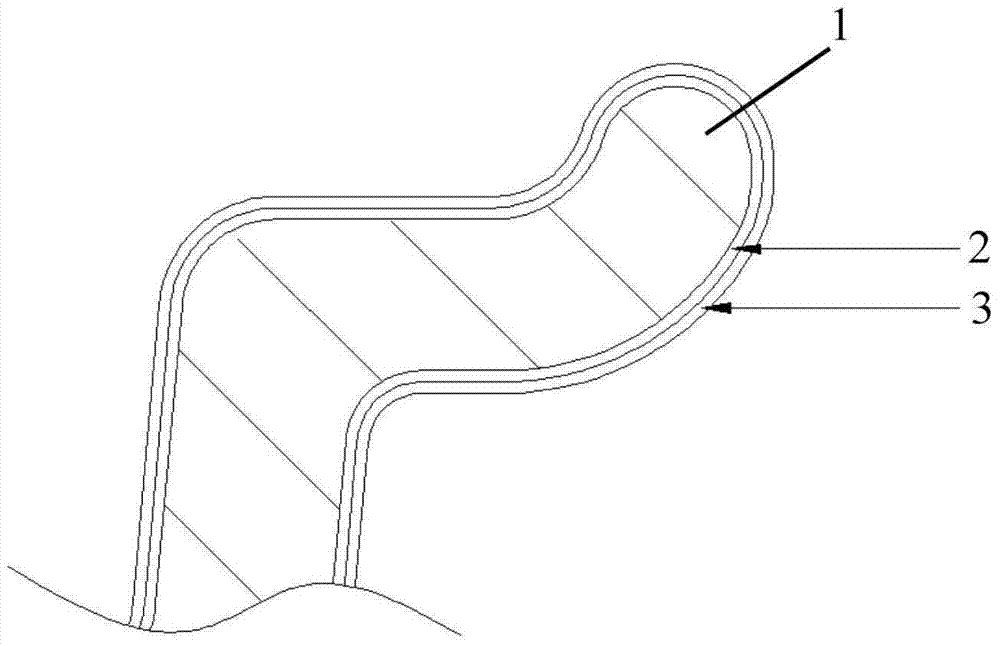

[0031] Such as figure 1 Shown is the embodiment 1 of the luminous safety hub described in the invention, including a hub body 1, a primer layer 2, and a luminous paint layer 3. The primer layer 2 is coated on the outer surface of the hub body 1, and the luminous paint layer 3 is coated on the outer surface of primer layer 2.

[0032] Preferably, the primer layer 2 has a thickness of 5-10 μm.

[0033] Preferably, the thickness of the luminous paint layer 3 is 20-25 μm.

[0034] The steps of its manufacturing method are as follows:

[0035] (1) Wheel hub cleaning: Soak the hub in alkaline degreasing agent for 30 minutes, rinse it with a high-pressure water gun for 3 minutes after taking it out, and dry it for the first time at 130°C;

[0036] (2) Primer coating: Evenly coat the epoxy zinc-rich primer on the outer surface of the wheel hub after the first drying to form a primer layer, and then dry it for the second time at 130-140°C after the coating is completed;

[0037] (3...

Embodiment 2

[0044] The difference from Example 1 is that the components and parts by weight of the luminous paint are: 45 parts of fluorocarbon emulsion, SrAl 2 0 4 : 9 parts of Eu, 8 parts of nano-zinc oxide, 0.2 parts of titanate coupling agent, 0.7 parts of organic montmorillonite, 1.8 parts of polycarboxylate, 0.3 parts of silicone defoamer, non-ionic polyurethane associative leveling 0.5 parts of agent, 19 parts of mica powder, 7 parts of polyvinyl alcohol, 7.5 parts of epoxy resin, 3.2 parts of carboxyethyl cellulose, and 14 parts of deionized water.

Embodiment 3

[0046] The difference from Example 1 is that the components and parts by weight of the luminous paint are: 40 parts of fluorocarbon emulsion, Sr 4 Al 14 0 25 : 12 parts of Eu, Dy, 7.5 parts of nano zinc oxide, 0.2 parts of titanate coupling agent, 0.5 parts of organic montmorillonite, 1.2 parts of polycarboxylate, 0.3 parts of silicone defoamer, non-ionic polyurethane associative type 0.8 parts of leveling agent, 15 parts of kaolin, 8 parts of polyvinyl alcohol, 6.5 parts of epoxy resin, 3.6 parts of carboxyethyl cellulose, 16 parts of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap