A multi-color pearl powder printing process for printing and dyeing decorative cloth

A printing process and pearlescent powder technology, applied in the field of textile printing and dyeing, can solve the problems of blocking, staining and fading, and achieve the effect of meeting the needs of diversified colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

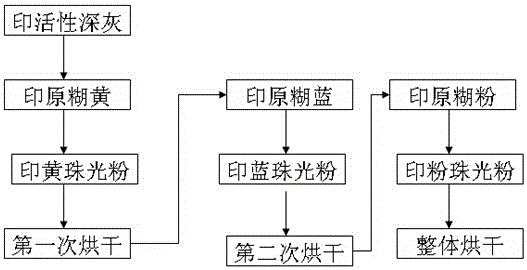

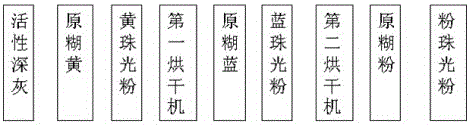

[0066] The present invention selects pure cotton combed 40S * 40S 133 * 88 105 " satin weaves as the fabric, the background color of the pattern is dyed cloth, the color is light gray, and the printing is 4 colors, wherein 1 color is active dark gray, and in addition The 3 colors are yellow pearl powder, blue pearl powder and pink pearl powder. Printing and typesetting are carried out after selecting fabrics. The typesetting is as follows Figure 4As shown, the layout from front to back is: active dark gray, original paste yellow, yellow pearl powder, first dryer, original paste blue, blue pearl powder, second dryer, original paste powder and powder pearl powder, Printing after typesetting, the printing process is as follows figure 2 shown, including the following steps:

[0067] The first step, printing active dark gray, the formula weight percent of active dark gray is:

[0068] Sodium alginate: 4.3%,

[0069] Urea: 10%,

[0070] Anti-staining salt S: 0.5%,

[0071] So...

specific Embodiment approach 2

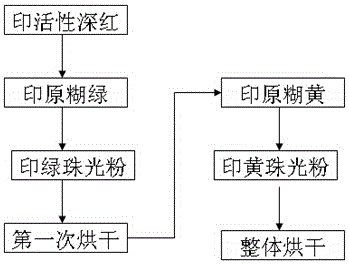

[0096] The present invention selects pure cotton carded 40S * 40S 133 * 72 105 " twill as the fabric, the background color of the flower pattern is dyed cloth, the color is bright red, and the printing is 3 colors, one of which is reactive deep red, and the other 2 The two colors are green pearl powder and yellow pearl powder. After selecting the fabric, the printing and typesetting are carried out. The typesetting is as follows Figure 5 As shown, the typesetting from front to back is as follows: active deep red, original paste green, green pearl powder, first dryer, original paste yellow and yellow pearl powder, and printing is carried out after typesetting. The printing process is as follows image 3 shown, including the following steps:

[0097] The first step, printing reactive crimson, the formula weight percent of reactive crimson is:

[0098] Sodium alginate: 4.3%,

[0099] Urea: 10%,

[0100] Anti-staining salt S: 0.5%,

[0101] Soda ash: 0.5%,

[0102] Baking so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com