A prestressed jack quick installation auxiliary device and its installation method

An installation assistance, jack technology, applied in construction, building structure, construction material processing and other directions, can solve problems such as low efficiency and difficult jack installation, avoid cross twisting, improve installation accuracy and work efficiency, Guarantee the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

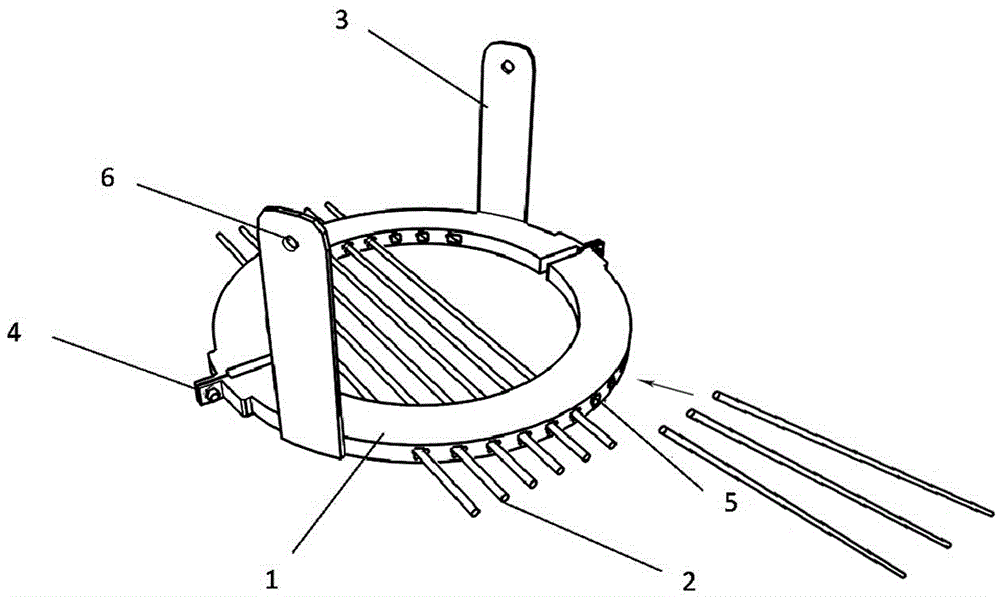

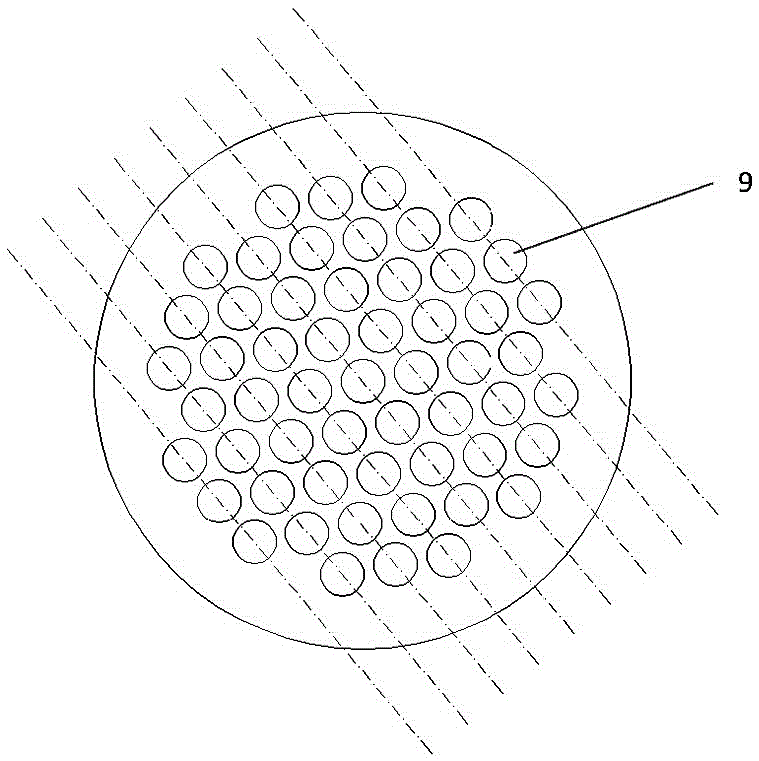

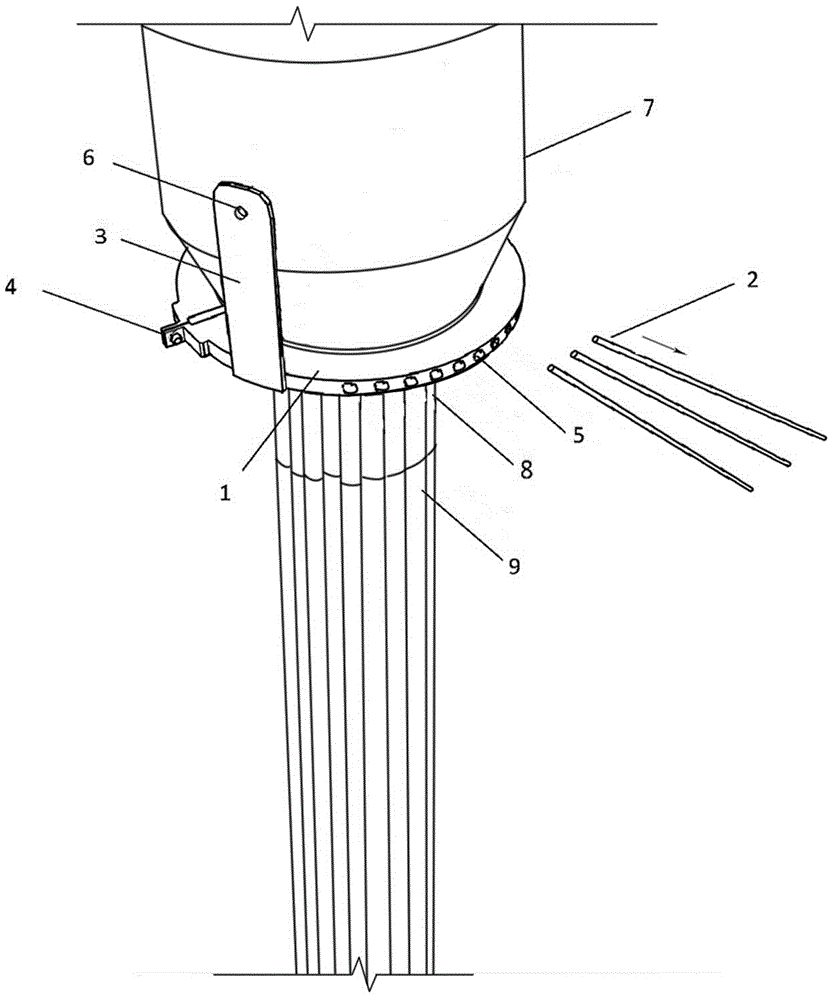

[0030] Examples see figure 1 As shown, this prestressed jack quick installation auxiliary device includes an annular bottom bracket formed by butting two semi-annular brackets 1, a positioning connecting plate 3 vertically connected to the side wall of the semi-annular bracket and a A group of horizontal steel needles 2 horizontally passing through the two semicircular supports 1 in turn.

[0031] The inner diameter of the annular bottom support is adapted to the outer diameter of the upper port of the tension jack 7, and a group of steel needle holes passing through the horizontal steel needle 2 are opened between the inner arc surface and the outer arc surface of each semi-circular support 1 5, and the steel pinholes on the two semi-circular supports are in one-to-one correspondence with each other in the horizontal direction after docking; both ends of the two semi-circular supports 1 are connected by fasteners; the semi-circular supports Both ends of 1 have a mating lug 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com