Flushing water pressure control system and control method for muddy water shield machine

A pressure control and shield machine technology, applied in the field of shield machines, can solve the problems of huge fluctuations in water supply pressure and frequent start-up of booster pumps, and achieve the effects of preventing water supply pressure fluctuations, reducing the number of starts, and stabilizing the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

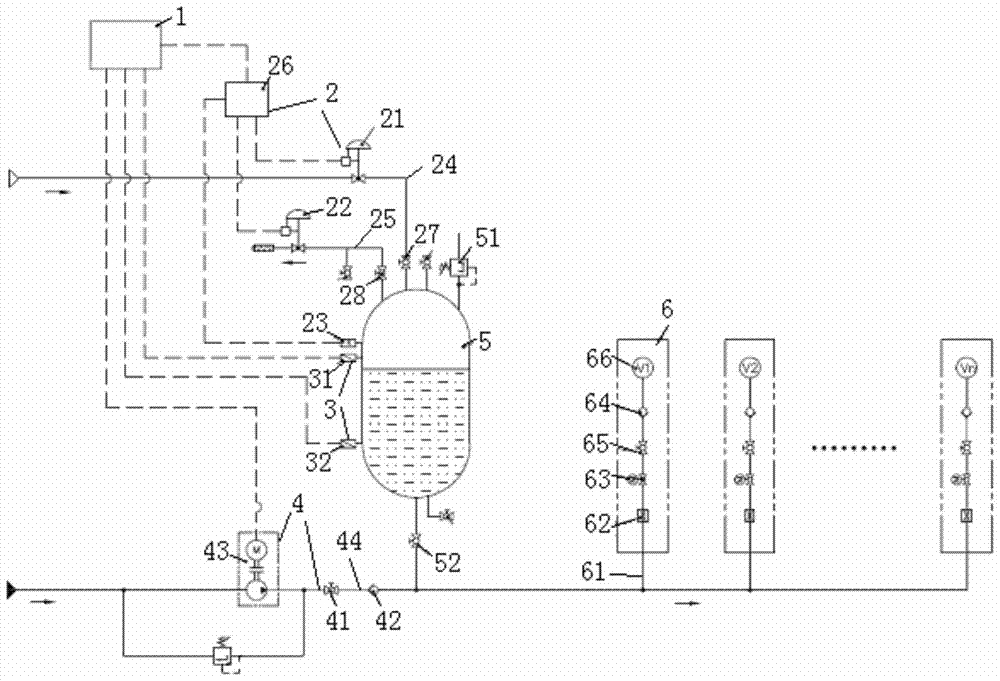

[0057] Embodiment one: if figure 1 As shown, the initial state adjustment of the system: before starting the system, set the pressure holding value of the valve controller 26 (that is, the pressure value required to be controlled by the pressure holding system) and the take-off pressure of the safety valve 51, and adjust the pressure on the terminal flushing pipeline 61. The opening of the electric ball valve 63, keep the manual ball valves 27, 28 in the closed state, the electric ball valve 63 in the closed state, and the manual ball valves 41, 65 in the open state, then start the booster pump unit 43 to start flushing the pipeline and the water tank 5 Fill water, when the liquid level in the water tank reaches the position of the high level liquid level switch 31, the liquid level switch sends a message, the PLC controller sends an instruction to stop the booster water pump unit, then opens the manual ball valve 27, 28, starts the air pressure maintaining system, the system ...

Embodiment 2

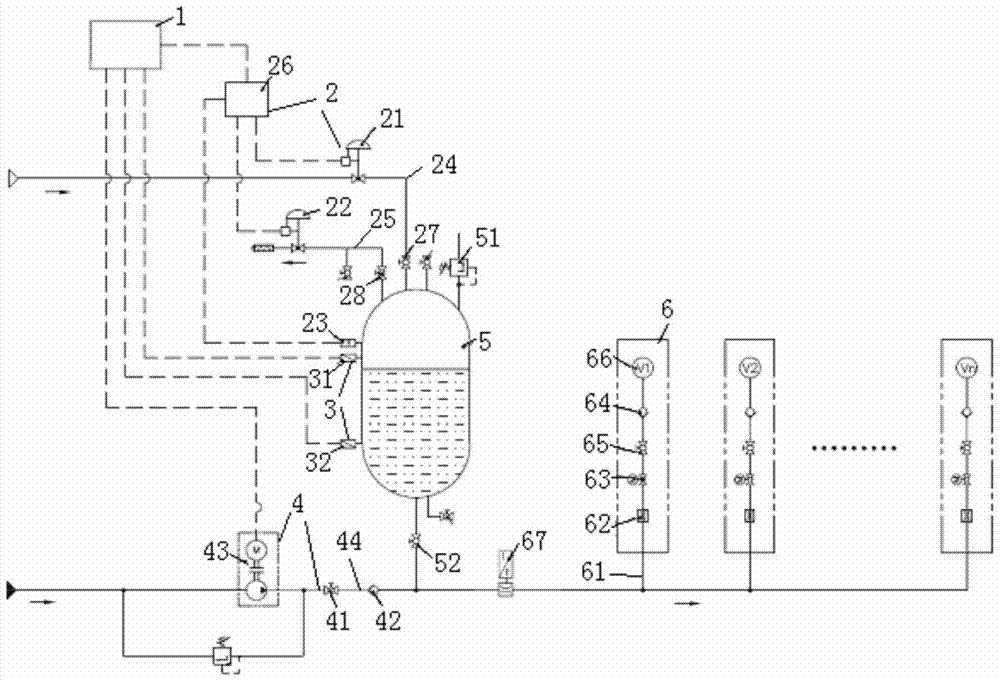

[0062] As a further improvement of the first embodiment, an electromagnetic flowmeter 67 is added to the main pipeline between the first one-way valve 42 and the terminal flushing pipeline 61 . During the working period of the pipeline system, the electromagnetic flowmeter detects the flushing water flow consumed by the main pipeline in real time and transmits it to the PLC controller 1 . In the valve flushing state, when the number of ball valves flushing at the same time is large, resulting in the instantaneous flushing water consumption exceeding the set value in the control program, the PLC controller 1 starts the booster water pump unit 43, and the water pump and the water tank work together to Plumbing system for water supply. This solution is especially suitable for the situation where there are a large number of terminal flushing pipelines 61 (such as the flushing water pipeline system on a muddy water shield with a large diameter).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com