A terminal release type torque limiting valve and a hydraulic control torque limiting system equipped with the valve

A technology for limiting valves and torque, applied in the field of hydraulic control torque limiting systems, can solve the problems of cranes operating after the force limit, high cost, low reliability, etc., to reduce the pressure change rate, increase stability, and flow capacity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

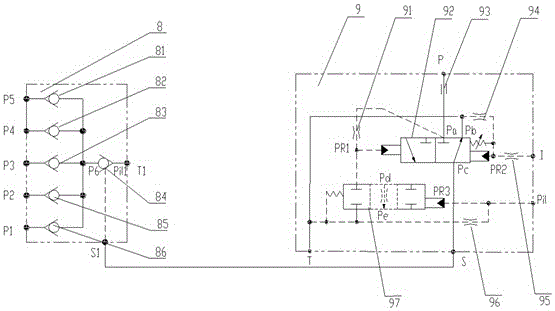

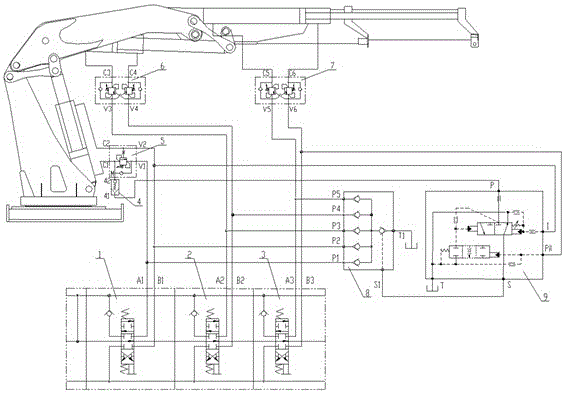

[0037] like figure 1 and figure 2 As shown, the terminal release type torque limiting valve includes a torque limiting unloading valve 8 and a torque limiting control valve 9;

[0038] The torque limiting unloading valve 8 includes a first one-way valve 81, a second one-way valve 82, a third one-way valve 83, a hydraulic control one-way valve 84, a fourth one-way valve 85 and a fifth one-way valve 86. The limit unloading valve 8 is equipped with the first oil port P1 of the torque limit unloading valve, the second oil port P2 of the torque limit unloading valve, the third oil port P3 of the torque limit unloading valve, and the fourth oil port of the torque limit unloading valve P4, the fifth oil port P5 of the torque limiting unloading valve, the oil return port T1 of the torque limiting unloading valve, the control oil port S1 of the torque limiting unloading valve, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com