Stainless steel backflow prevention device with double non-return valves

A technology of backflow preventer and double check valve, which is applied in multi-way valves, control valves, valve devices, etc., can solve the problems of large volume, unfavorable installation, and heavy weight, and achieve small volume, prevent backflow pollution, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

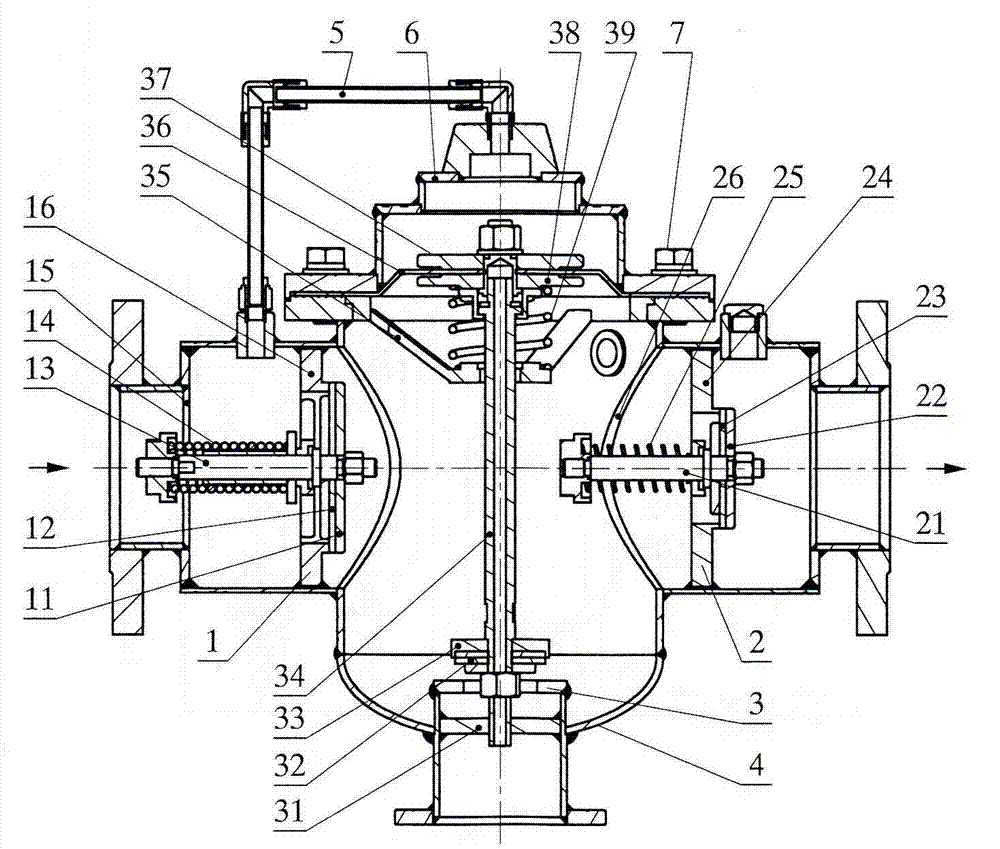

[0012] attached below figure 1 The double check valve stainless steel backflow preventer of the present invention will be described in detail below.

[0013] as attached figure 1 As shown, the double check valve stainless steel backflow preventer of the present invention is mainly composed of a valve body 4, a valve cover 6, a water inlet check valve 1, a water outlet check valve 2, a hydraulic control drain valve 3 and a connecting pipe 5. The check valve 1 and the water outlet check valve 2 are respectively located at both ends of the valve body 4, and a hydraulic control drain valve 3 is installed in the valve body 4 between the water inlet check valve 1 and the water outlet check valve 3, and the valve body 4 The upper part of the upper part is fixed with a valve cover 6 by bolts 7. The water inlet check valve 1 includes a valve disc 11, a valve stem 13, a spring 14, a guide seat 15 and a valve seat 16. The guide seat 15 and the valve seat 16 are respectively located at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com