Closing device for steam pipe

A closed device and steam pipeline technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve the problems of reduced heat preservation effect, large relative displacement, poor effect, etc., to improve service life and improve The effect of reliability and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

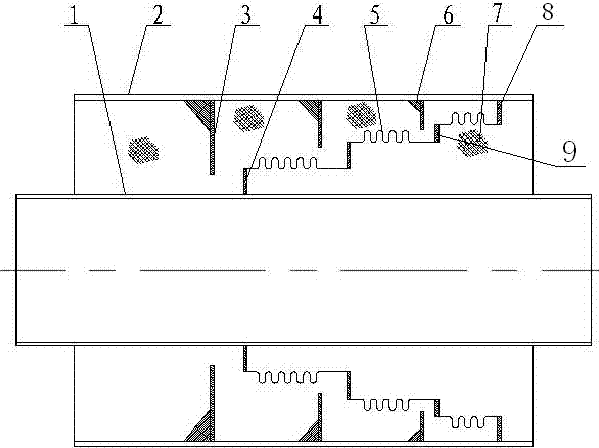

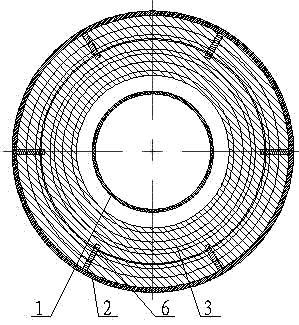

[0010] A large-displacement pipe end sealing device for steam pipelines, which includes: a working tube 1, an outer protective tube 2, and a closing assembly, the sealing assembly is arranged between the working tube 1 and the outer protective tube 2; the sealing assembly includes: a plurality of different Diameter connecting ring plate 4, multiple limiting plates 3 of different diameters, multiple reinforcing rib plates 6, multiple corrugated pipes 5 and high temperature heat-resistant insulation material 7; limiting plate 3 is connected to the inner wall of outer protective tube 2 and uses reinforcing ribs The positioning of the plate 6; the first connecting ring plate 4 is connected to the working pipe 1 and the corrugated pipe 5, the second connecting ring plate 8 is connected to the corrugated pipe 5 and the outer protection pipe 2, and several third connecting ring plates 9 are connected to the corrugated pipe 5 and another corrugated pipe Tube 5; working tube 1 and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com