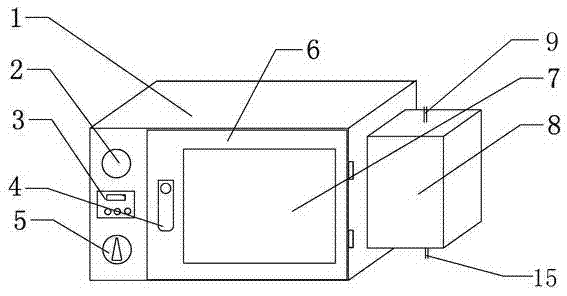

Vacuum freeze drying device

A technology of vacuum freeze-drying and freeze-drying chambers, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., which can solve the problems of high purchase and maintenance costs, high cost, and easy damage, and improve heat transfer efficiency , improve efficiency, and ensure the effect of freezing low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

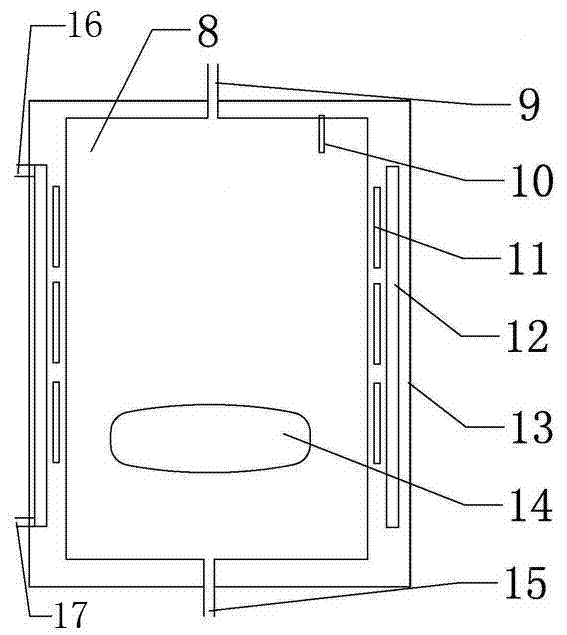

[0019] As shown in the figure, a vacuum freeze-drying device includes a freeze-drying bin 1, a water-catching bin 8 and refrigeration equipment arranged outside the water-catching bin 8, and the freeze-drying bin 1 passes through a connection hole provided on the side wall of the water-catching bin 8 14 communicates with the water catcher 8 and makes the joint seal. The refrigeration equipment includes an electric cooling plate 11, a water cooling plate 12 and an insulation layer 13. The cooling surface of the electric cold plate 11 is close to the outside of the water catcher 8. The outer side of the electric cold plate 11 is a heating surface, and the heating surface is fitted with the water cooling plate 12. The outer layer of the water cooling plate 12 is provided with an insulation layer 13 around the water catcher 8. The water catcher 8 is connected to the electric The gaps between the cold plates 11, between the electric cold plates 11 and the water-cooled plates 12, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com