Long period fiber grating and its preparation method

A fiber grating and long-period technology, which is applied to cladding optical fiber, optical waveguide, light guide, etc., can solve the problems of complex preparation process, high cost, unstable control of fiber grating period, etc., to achieve promotion, low cost, and production The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below with reference to the accompanying drawings.

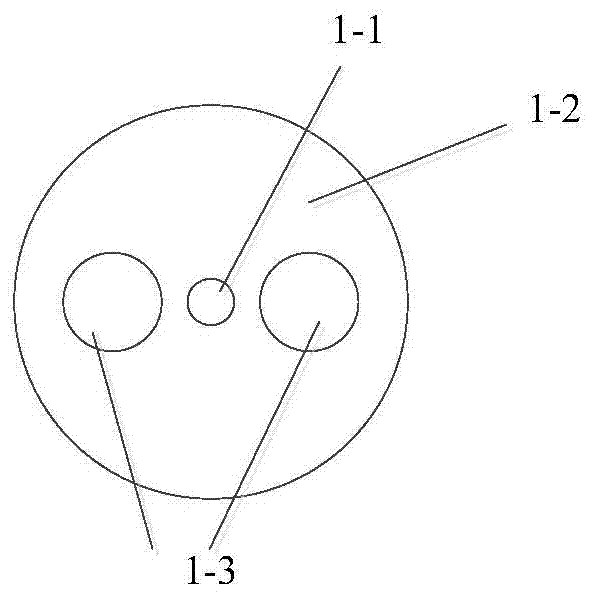

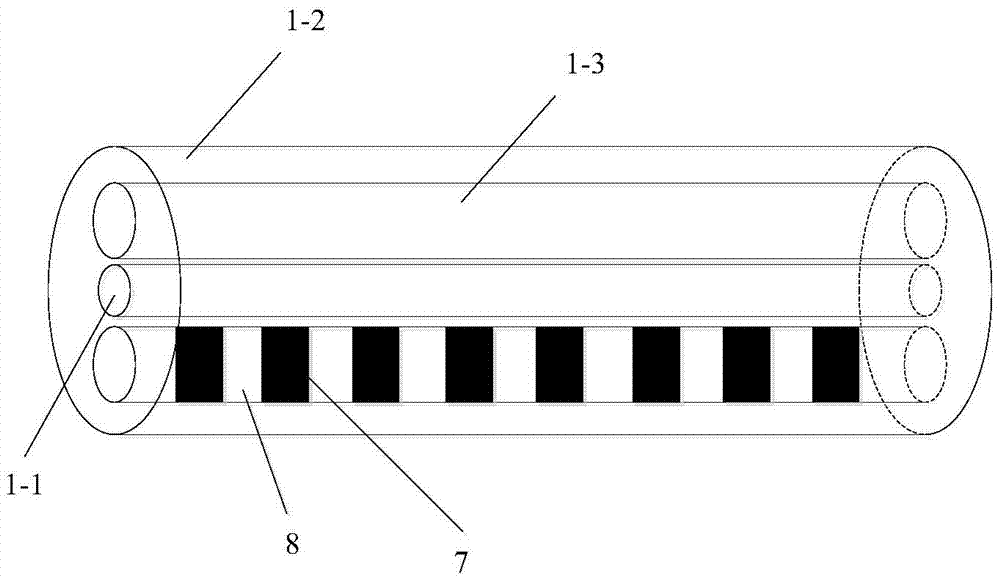

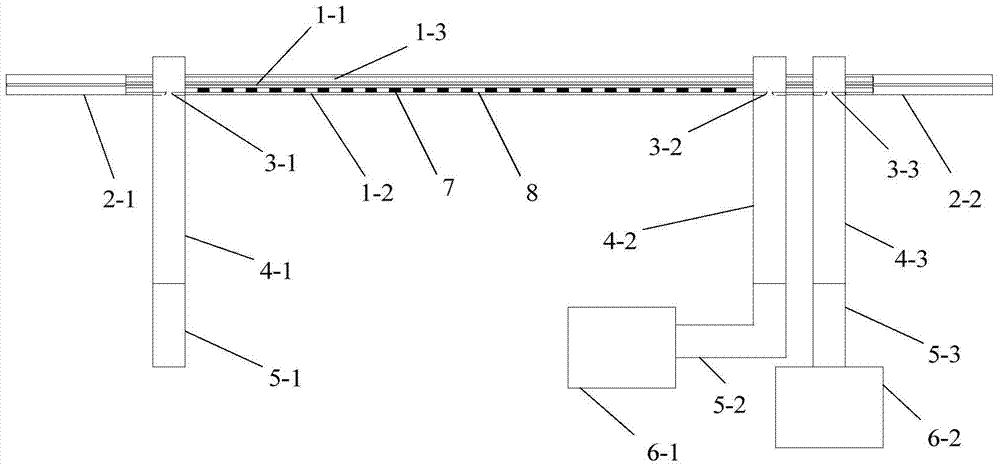

[0027] combine figure 2 , the long-period fiber grating includes the edge hole fiber to be written into the fiber grating after the hole reaming process. With reference to Figure 1(a) to Figure 1(b), the edge hole fiber includes: 1-1-fiber core, 1-2- Cladding, 1-3-air cavity; also includes ordinary optical fibers 2-1, 2-2 welded to both ends of the edge-hole optical fiber respectively, and holes 3-1 on the side of the optical fiber at a distance from one end face of the optical fiber to which the grating is to be written , the two holes 3-2, 3-3 on the side of the optical fiber at a distance from the other end face of the optical fiber to be written into the grating are axially sleeved into the optical fiber and fixed in the holes 3-1, 3-2, 3- Steel pipes 4-1, 4-2, 4-3 at 3 places, PTFE sleeves 5-1, 5-2, 5-3 connected to the steel pipes at one end, and PTFE sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com