Method for indenting square back by using digital indenting machine

A digital creasing machine, creasing machine technology, applied in book binding flattening machine, book binding, printing, etc., can solve the problems of high production cost, unstable binding quality, etc., and achieve good flatness and overall beautiful appearance , parameter adjustment flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

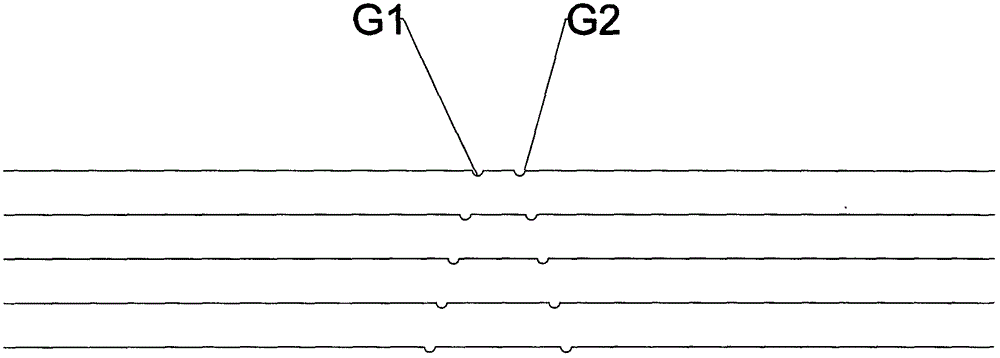

[0019] like figure 1 As shown, a method of using a digital creasing machine to realize square ridge indentation includes the following steps:

[0020] A method for realizing square ridge creasing by using a digital creasing machine, comprising the following steps:

[0021] S01: Determine the position G1 of the first front mark, the position G2 of the first back mark, and the variable distance coefficient X;

[0022] S02: Send the i-th sheet of paper into the creasing section of the creasing machine, input the position of the first front mark G1, the position of the first back mark G2, the variable distance coefficient X, and the number of sheets i, and calculate the position S of the front mark of the i-th paper i1 , paper trailing position S i2 should satisfy the calculation formula:

[0023] S i1 =G1-(i-1)*X(1≤i≤N)

[0024] S i2 =G2+(i-1)*X(1≤i≤N)

[0025] Where N is the total number of sheets of paper, and the variable distance coefficient X is a positive number.

...

Embodiment 2

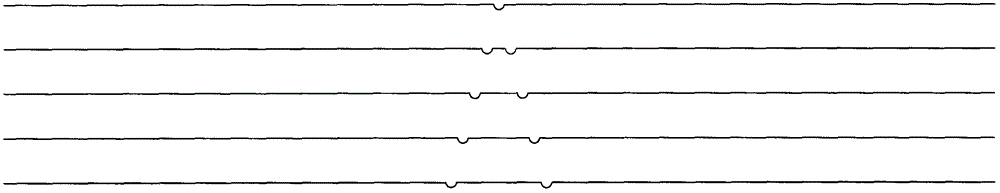

[0041] like figure 2 As shown, compared with Embodiment 1, in this embodiment, the front mark position G1 of step S02, the first back mark position G2, G1=G2, the first paper adopts single indentation.

[0042] After the paper is neatly stacked, the overall indentation position is in a triangular structure.

[0043] Taking the total number of books as 5 as an example, input the position of the first front mark G1 = 200mm, the position of the first back mark G2 = 200mm, and the variable distance coefficient X = 1mm. The specific indentation parameters are:

[0044] The specific indentation parameters are:

[0045] S 11 = S 12 =200-(1-1)*1=200mm

[0046] S 21 =200-(2-1)*1=199mm

[0047] S 22 =200+(2-1)*1=201mm

[0048] S 31 =200-(3-1)*1=198mm

[0049] S 32 =200+(3-1)*1=202mm

[0050] S 41 =200-(4-1)*1=197mm

[0051] S 42 =200+(4-1)*1=203mm

[0052] S 51 =200-(5-1)*1=196mm

[0053] S 52 =200+(5-1)*1=204mm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com