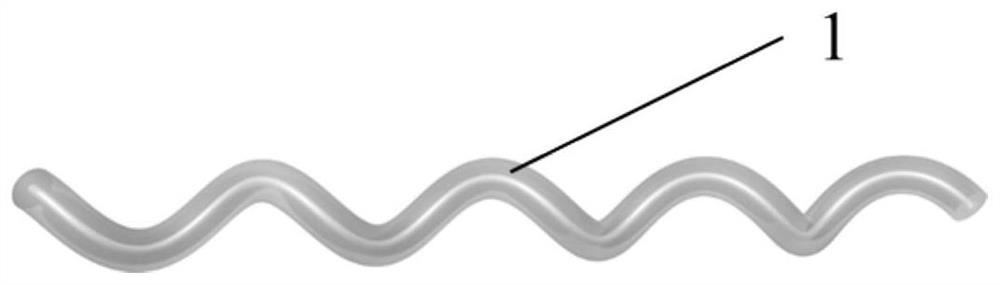

Flexible multifunctional metal wire capable of being bent at will and preparation method thereof

A multi-functional, metal wire technology, applied in the field of multi-functional materials, can solve the problems of hard texture, tensile strength, and poor bending resistance of metal wires, and achieve the effects of low cost, flexible and adjustable shape, and warm preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

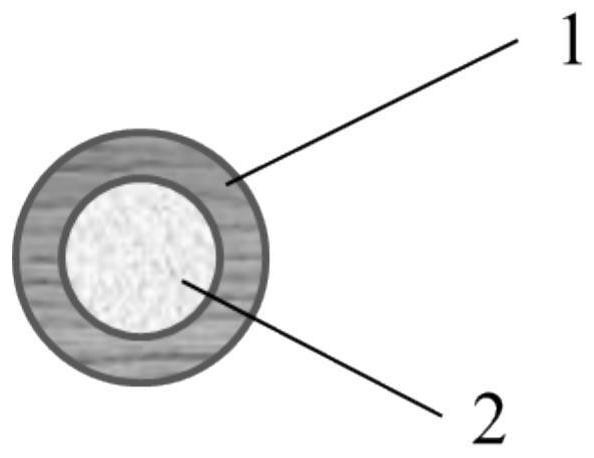

[0029] (1) Use a photosensitive resin 3D printer to print a solid cylinder with a diameter of 1mm and a length of 100mm, and hang it upright.

[0030] (2) 20g of liquid silica gel Ecoflex A component and 20g of Ecoflex B component were added to the beaker to form a uniform liquid polymer, then the container containing the mixture was placed on a 50°C electric hot plate, and magnetically stirred for 1 hour, A homogeneous mixture was obtained.

[0031] (3) Continuously pour the Ecoflex liquid silica gel obtained in step (2) on the outer surface of the cylinder obtained in step (1), until the surface of the cylinder is evenly covered by the Ecoflex liquid silica gel mixture, and the liquid silica gel is no longer directed toward the cylinder. After dripping, the cylinder was left hanging upright and left to cure for 12 hours.

[0032] (4) After the curing is completed, the liquid silica gel obtained in step (3) whose surface has been completely cured is gently taken out from the...

Embodiment 2

[0035] (1) Use a photosensitive resin 3D printer to print a solid cylinder with a diameter of 1.5mm and a length of 100mm, and hang it upright.

[0036] (2) 40 g of liquid silica gel Ecoflex A component and 40 g of Ecoflex B component were added to the beaker, and then the container containing the mixture was placed on a 50° C. electric hot plate and magnetically stirred for 1 hour to obtain a homogeneous liquid.

[0037] (3) continuously pouring the liquid obtained in step (2) on the outer surface of the cylinder obtained in step (1) until the surface of the cylinder is evenly covered by the liquid polymer and no longer drips downward, then The cylinder was left hanging upright and left to cure for 12 hours.

[0038] (4) After the solidification is completed, the liquid polymer obtained in step (3) whose surface has been completely solidified is gently taken out from the cylinder, and then a certain amount of liquid gallium indium alloy is poured into the syringe, and removed...

Embodiment 3

[0041] (1) Use a photosensitive resin 3D printer to print a solid cylinder with a diameter of 2mm and a length of 100mm, and hang it upright.

[0042] (2) 20g of liquid silica gel Ecoflex A component and 20g of Ecoflex B component were added to the beaker to form a uniform liquid polymer, then the container containing the mixture was placed on a 50°C electric hot plate, and magnetically stirred for 1 hour, A homogeneous mixture was obtained.

[0043] (3) Continuously pour the Ecoflex liquid silica gel obtained in step (1) on the outer surface of the cylinder obtained in step (1), until the surface of the cylinder is evenly covered by the Ecoflex liquid silica gel mixture, and the liquid silica gel is no longer directed toward the cylinder. After dripping, the cylinder was left hanging upright and left to cure for 12 hours.

[0044] (4) After the solidification is completed, gently take out the fully solidified liquid silica gel on the surface of the cylinder obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com