A kind of array substrate and manufacturing method thereof

An array substrate and substrate technology, which is applied in the field of flat panel display, can solve the problem of poor viewing angle in the oblique direction, and achieve the effect of improving the effect of wide viewing angle and good visual effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to illustrate the array substrate provided by the present invention and the manufacturing method thereof, the detailed description will be described below in conjunction with the accompanying drawings and text descriptions of the specification.

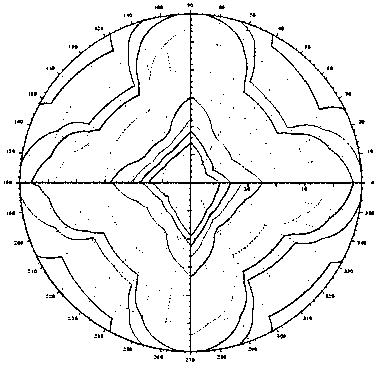

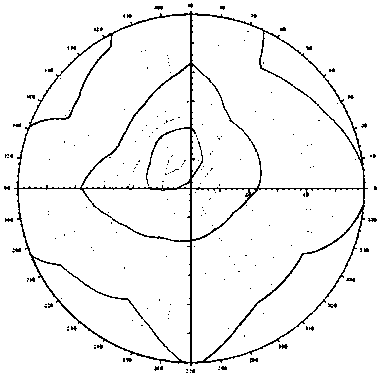

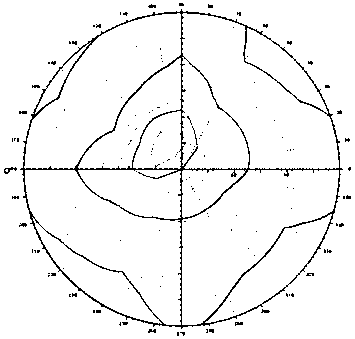

[0037] Please refer to Figure 5 , is a schematic structural view of an array substrate 200 according to a preferred embodiment of the present invention. The array substrate 200 can be a substrate in AIFF MVA mode, or an array substrate in other modes, and it at least includes a first surface 201a of the substrate 201, the first surface 201a is a continuous and smooth plane, in its embodiment, the first surface can be a curved surface or with an irregular surface, the substrate 201 is a transparent material such as hard Made of glass, rigid or flexible resin.

[0038]The array substrate 200 further includes a plurality of scanning lines 206 and a plurality of signal lines 205 formed on the first surface 201a of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com