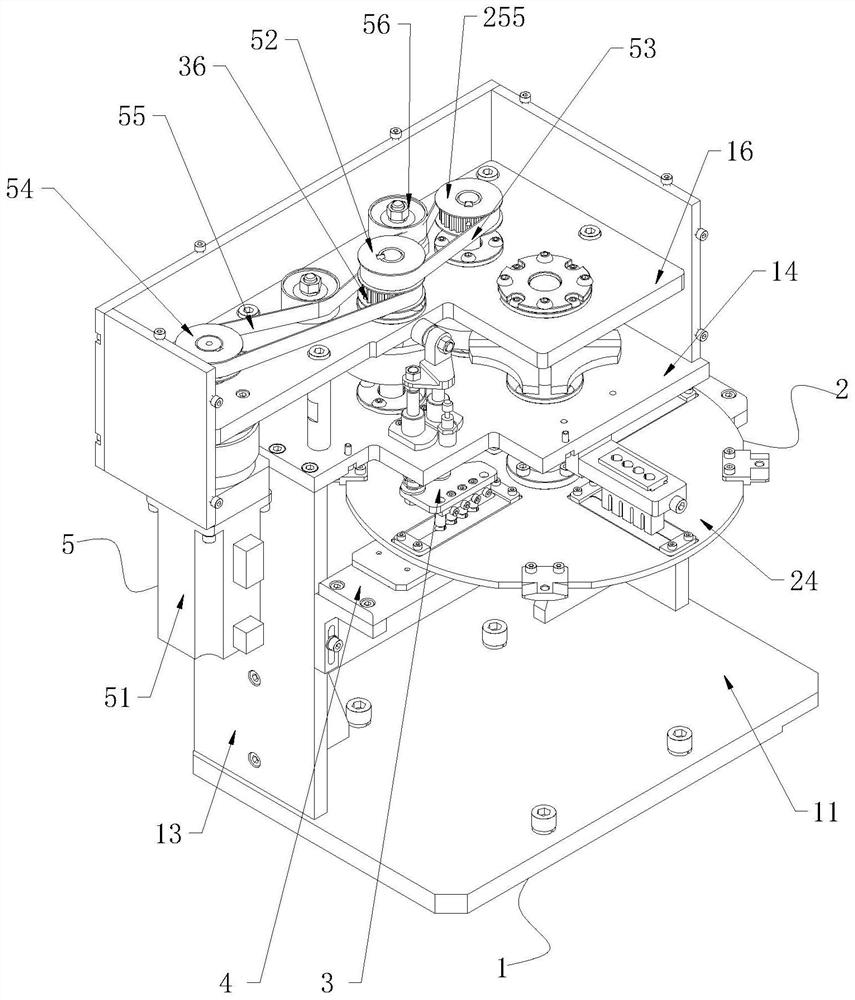

A fully automatic alignment device

An arrangement device, fully automatic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low operation efficiency, high equipment purchase cost and maintenance cost, and achieve the effect of improving production efficiency and high accuracy of arrangement position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

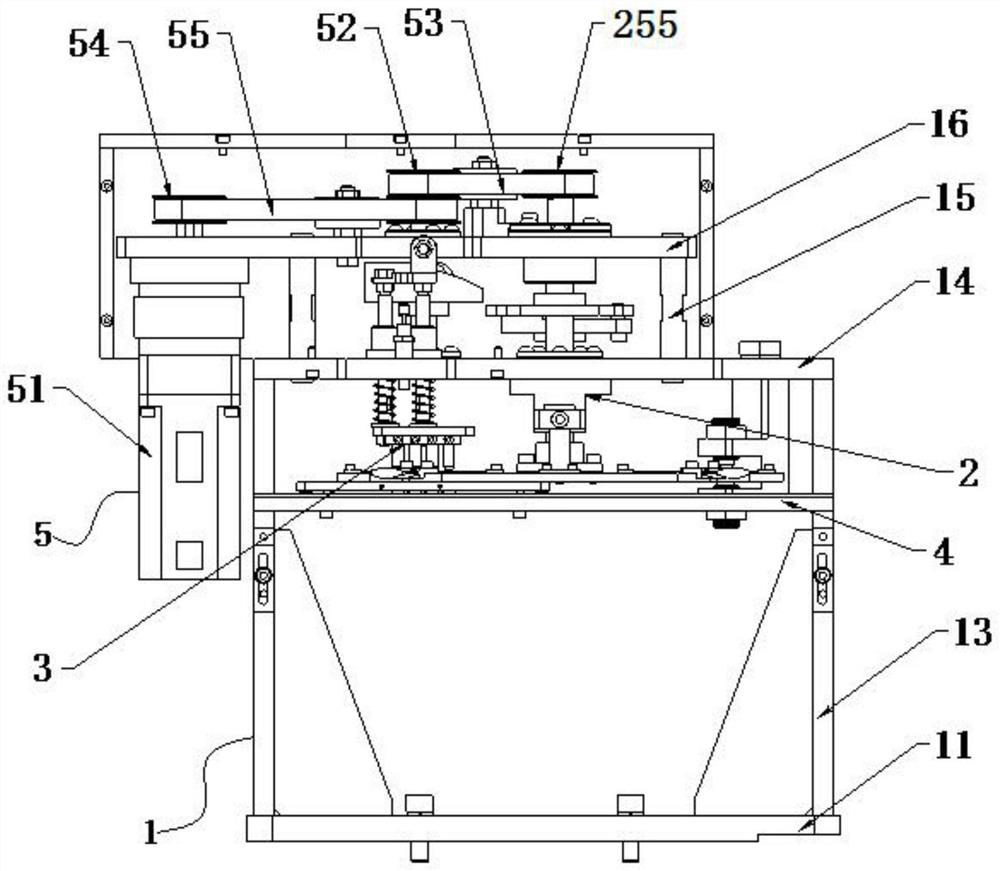

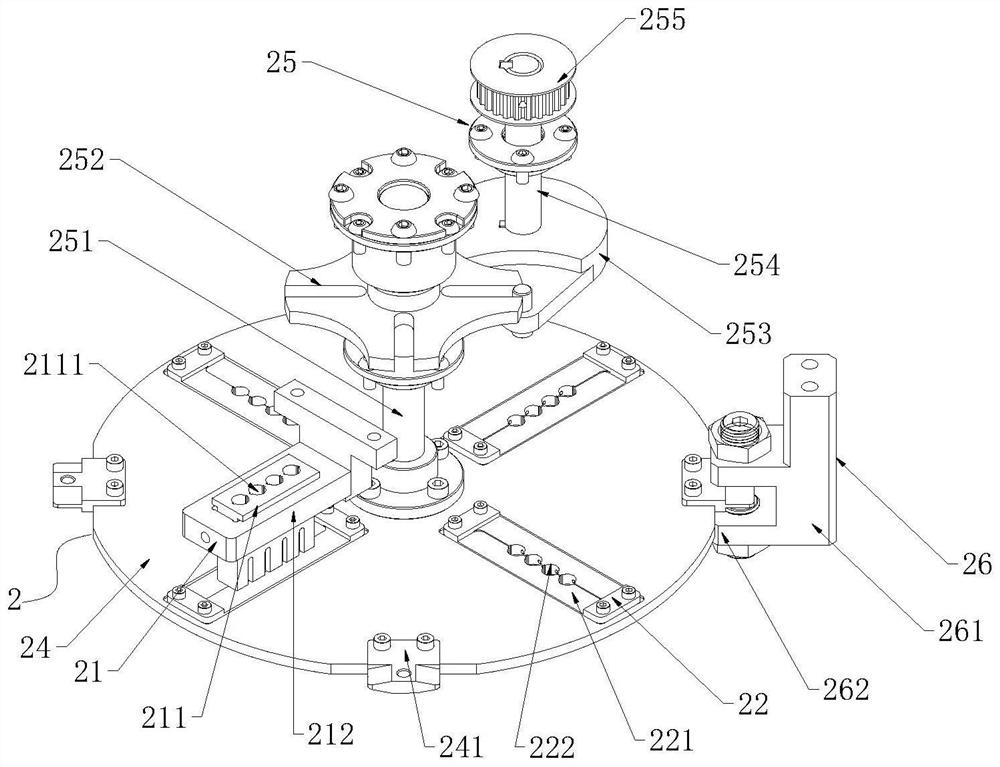

[0057] In this implementation, the aligning mechanism 2 and the punching mechanism 3 are driven by synchronous belts, including a power mechanism 5 for driving the alignment mechanism 2 and the punching mechanism 3 to move. The power mechanism 5 includes a motor 51 for connecting with the first slave The first driving wheel 52 corresponding to the driving wheel 255 , the second driving wheel 54 corresponding to the second driven wheel 36 , the first driving wheel 52 and the first synchronous belt 53 connected to the first driven wheel 255 , the second driving wheel 54 and the second driven wheel 36 are connected with a second timing belt 55, the motor 51 is mounted on the second mounting plate 16, and the second driving wheel 54 is mounted on the rotor of the motor 51, so The first driving wheel 52 is connected with the first driven wheel 255, the first driving wheel 52 is coaxially installed with the second driven wheel 36, and the outer sides of the first timing belt 53 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com