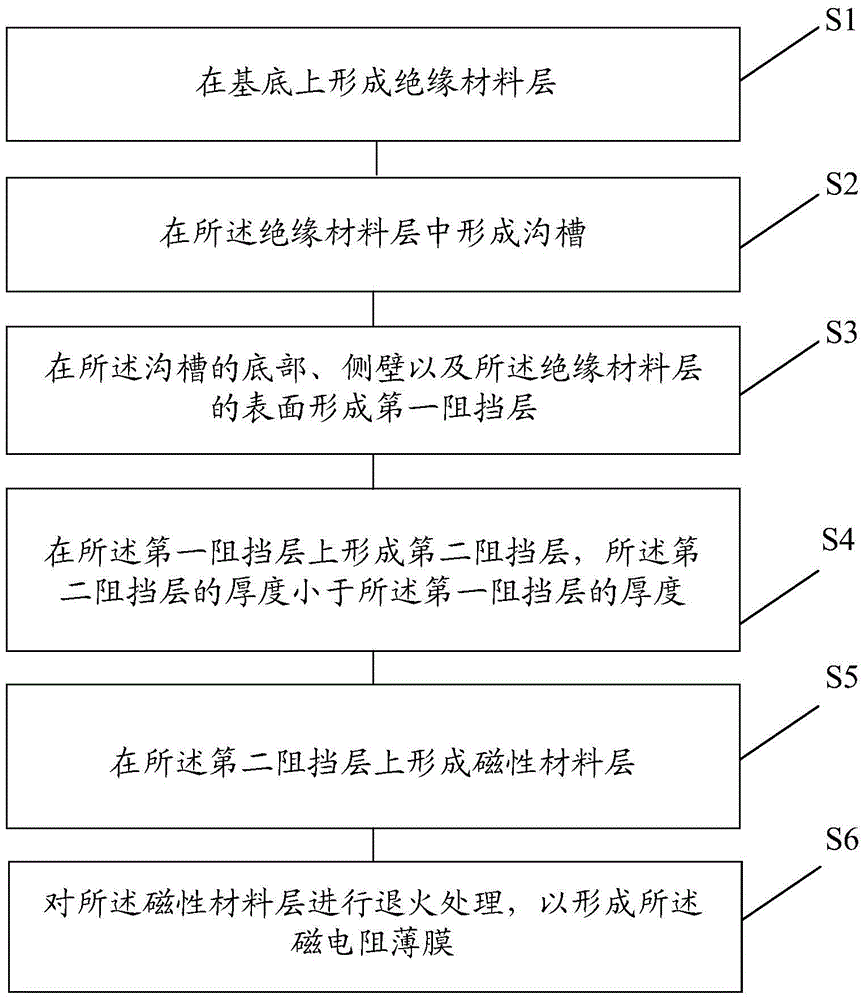

Magnetoresistive thin film and its manufacturing method

A manufacturing method and magnetoresistance technology, applied in the field of magnetic sensors, can solve the problems of poor stability and occupation of information storage devices, and achieve the effects of improving the relative change rate of anisotropic magnetoresistance, increasing the relative change rate, and aligning crystal grains neatly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

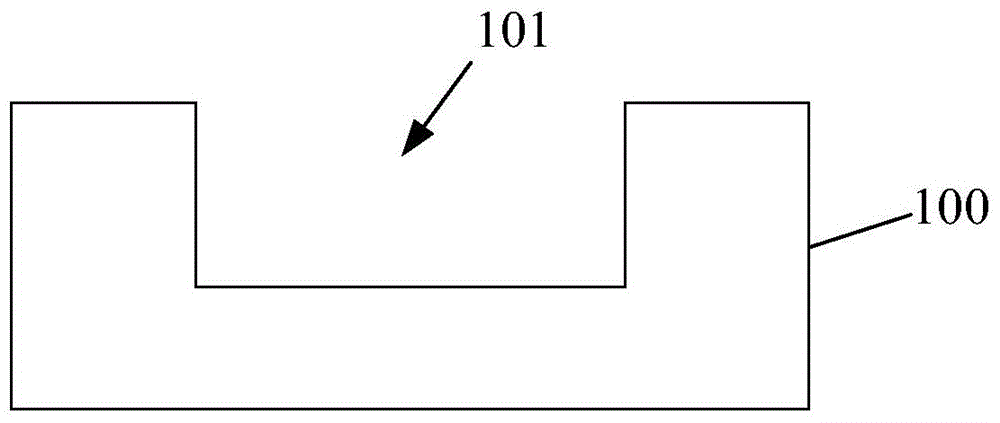

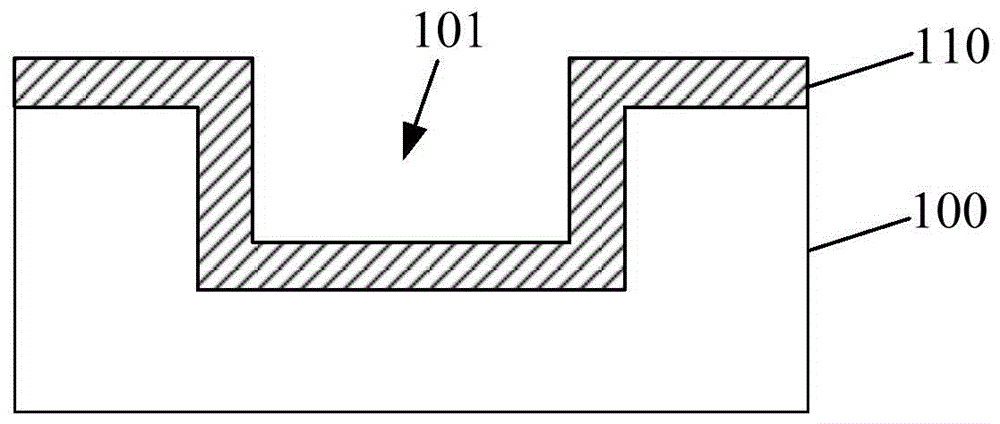

[0037] The relative rate of change of the anisotropic magnetoresistance of the existing magnetoresistance thin film is relatively low. Through the research on the formation process of the magnetic material layer in the anisotropic magnetoresistance, it is found that the orderly degree of crystal grain arrangement in the magnetic material layer is related to that of the magnetic material. The roughness of the layer growth surface is related to:

[0038] The rougher the growth surface of the magnetic material layer is, the more irregular the grain arrangement of the magnetic material layer is. The more irregular the arrangement of the magnetic material layer is, the easier it is to reduce the relative change rate of the anisotropic magnetoresistance of the magnetic material layer.

[0039] Therefore, reducing the roughness of the growth surface of the magnetic material layer is beneficial to the regular arrangement of crystal grains in the magnetic material layer, thereby increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com