Touch control display panel, touch control display device and production method

A touch display panel and touch display device technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of increased production cost and unfavorable production efficiency, and achieve simplified structure and offset Effect of Potential Disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

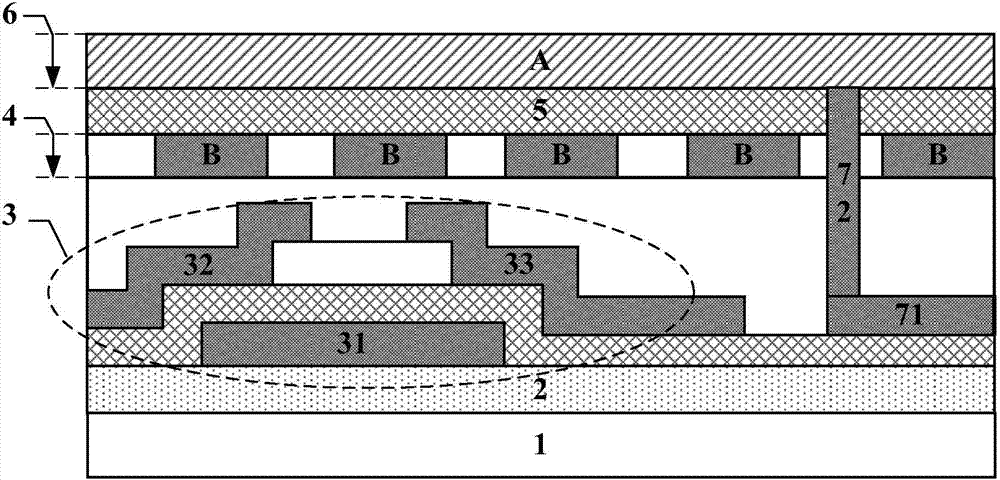

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0031] The solution of the present invention provides a brand-new touch display panel with a built-in touch screen structure. The cathode used as a common electrode is multiplexed as a touch electrode to achieve the purpose of simplifying the structure, thereby reducing the manufacturing process of the touch display panel. and reduce manufacturing costs.

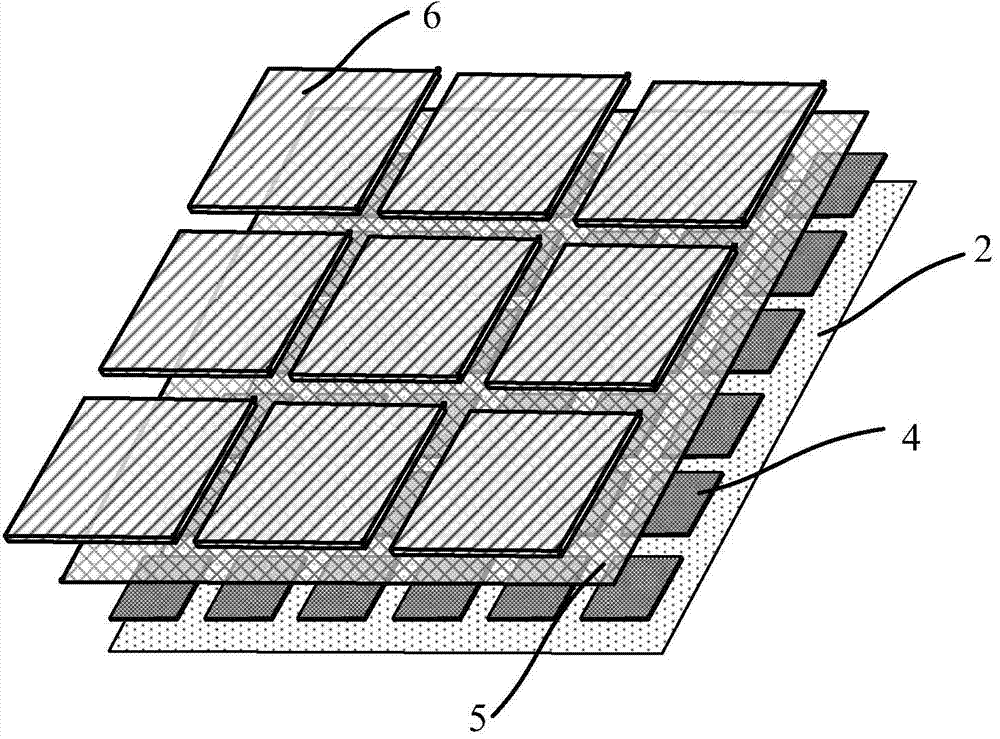

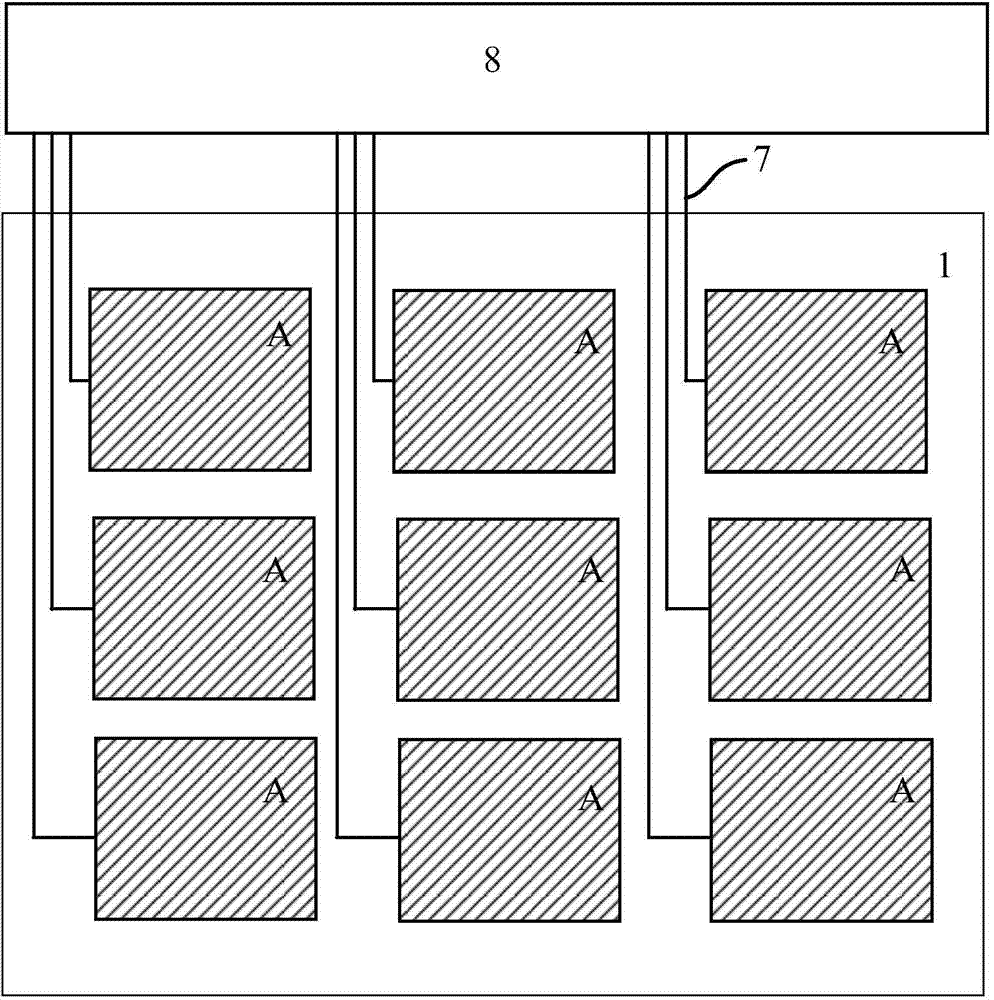

[0032] Wherein, the array substrate mentioned in the embodiment of the present invention includes: an array substrate (that is, the first substrate) and a color filter substrate (that is, the second substrate) that are oppositely arranged, such as figure 1 As shown, the array substrate specifically includes:

[0033] Substrate substrate ( figure 1 not shown);

[0034] An anode 4 formed on the base s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com