Connection device between motor and oil pump

A connecting device and oil pump technology, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of difficult connection, increased noise, increased equipment expenditure, etc., and achieves compact connection structure, extended service life, and increased versatility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

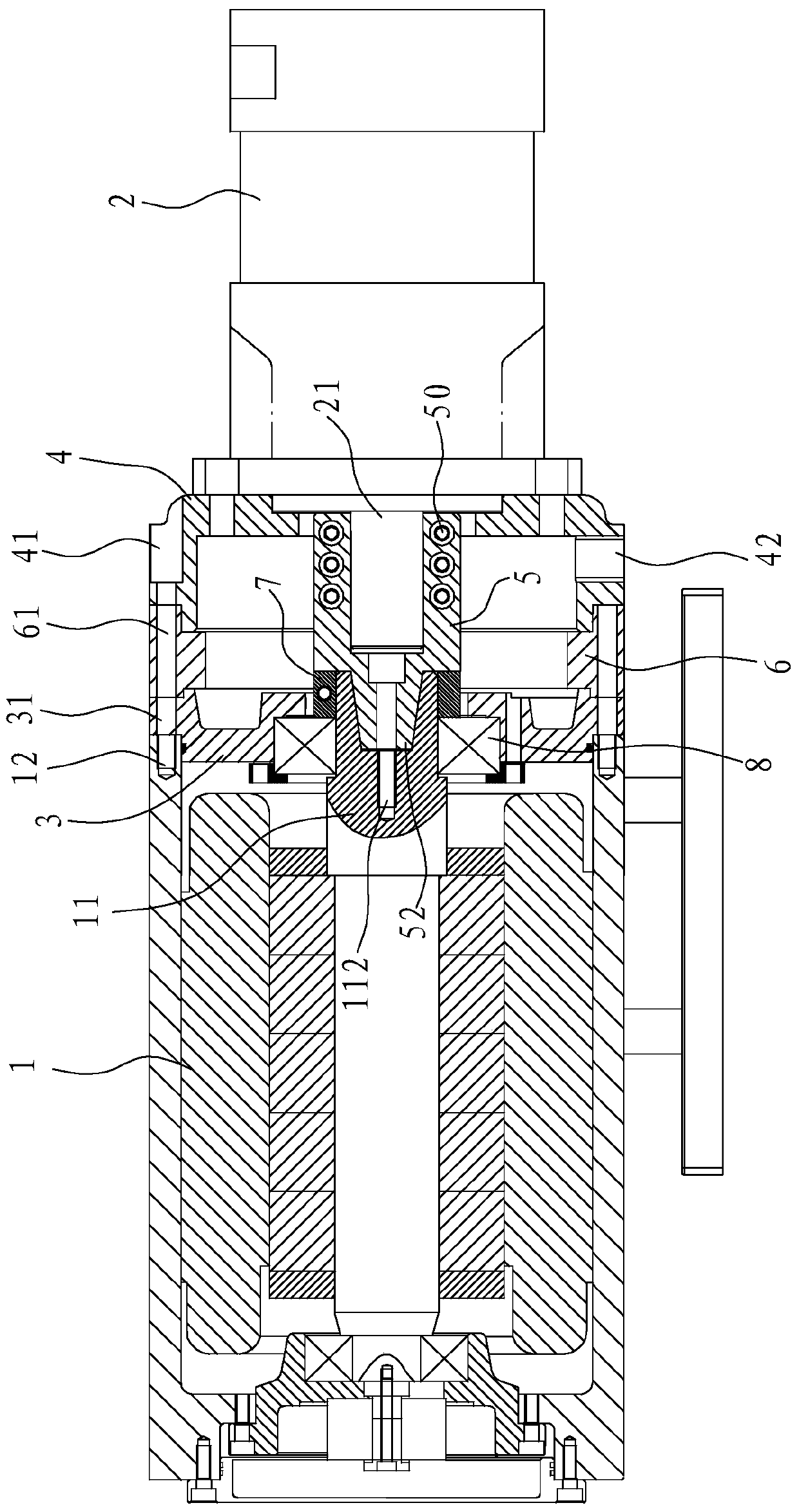

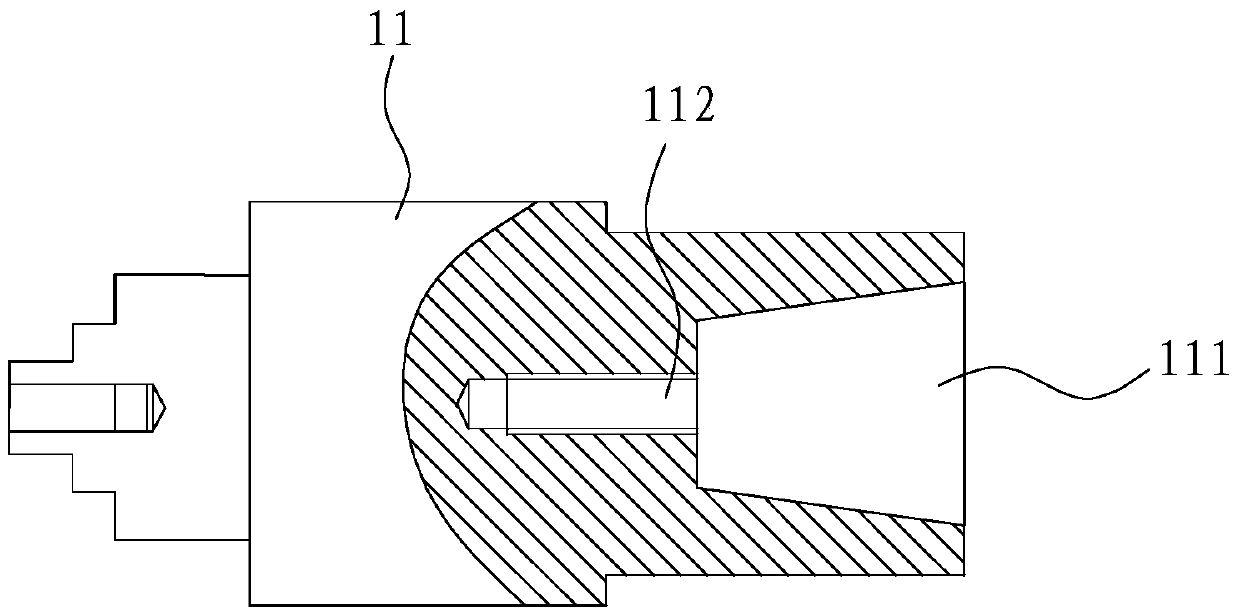

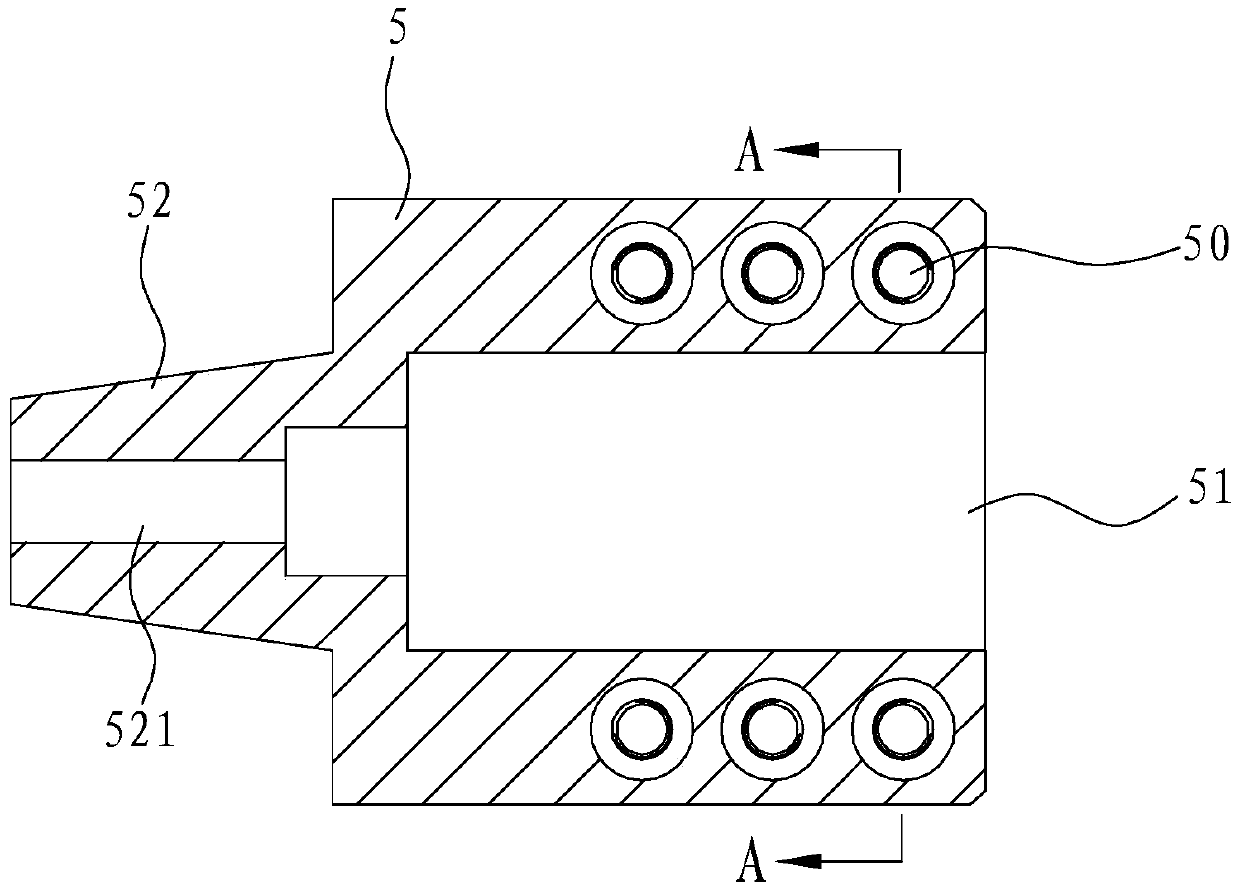

[0028] A connection device between a motor and an oil pump, such as Figure 1~4 As shown, it includes a first end cover 3 and a second end cover 4 connected to the motor 1 and the oil pump 2 respectively. The first end cover 3 is provided with a first mouth extending from the output shaft 11 of the power supply. The second end cover 4 is provided with a second mouth part protruding from the input shaft 21 of the oil supply pump, and the first end cover 3 and the second end cover 4 are respectively provided with matching connecting mechanisms. The second threaded hole 12, the connection mechanism is the second through hole 31 and the third through hole 41 respectively opened on the first end cover 3 and the second end cover 4, the second through hole 31, the third through hole 41 and the first through hole 41 The two threaded holes 12 are arra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap