Permanent magnetic differential drive mechanism

A differential transmission and permanent magnet technology, which is applied in the field of transmission mechanism and permanent magnet differential transmission mechanism, can solve the problems of not being suitable for large-scale use, unable to change the transmission ratio, and high technical requirements, so as to reduce the moving distance and save permanent magnets , Improve the effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing of description, the present invention will be further described.

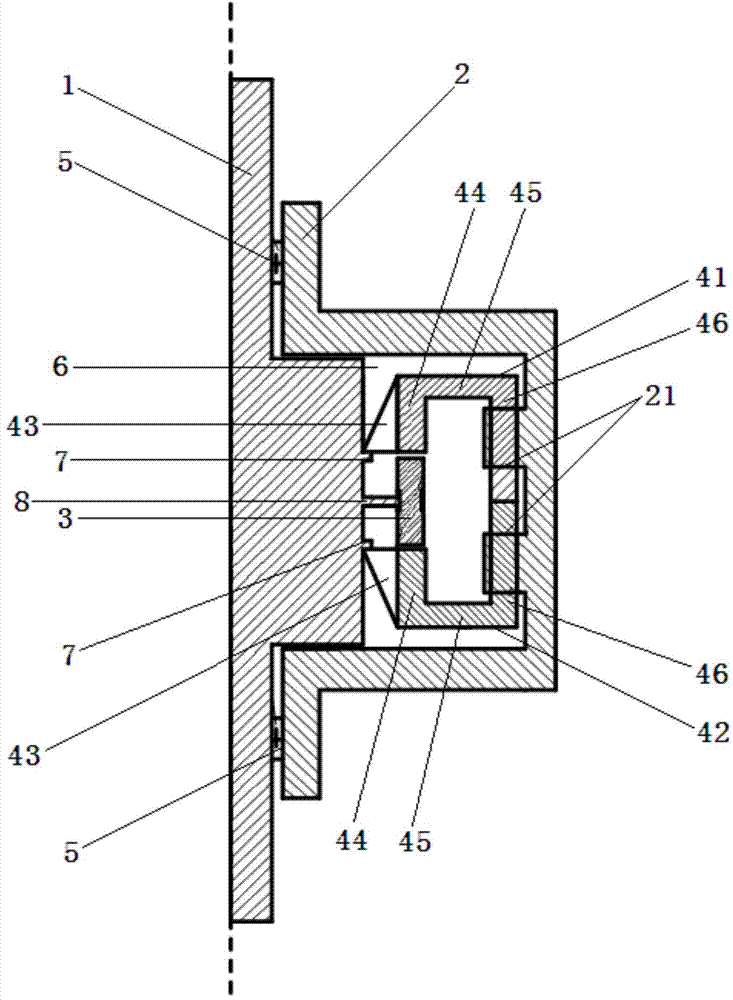

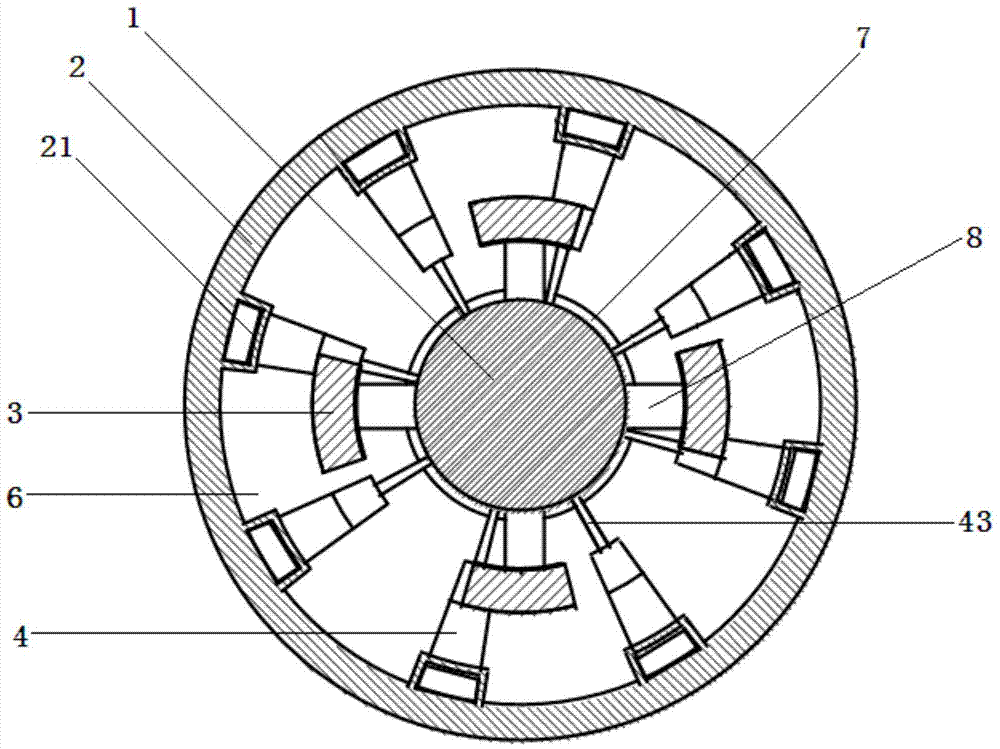

[0029] Such as figure 1 and figure 2 As shown, a permanent magnet differential transmission mechanism includes an inner shaft 1, an outer shaft 2, a permanent magnet rotor 3 and a magnetically permeable rotor 4. The magnetically permeable rotor 4 includes a first ferromagnetic block 41 and a second ferromagnetic block 41 arranged symmetrically. Two ferromagnetic blocks 42.

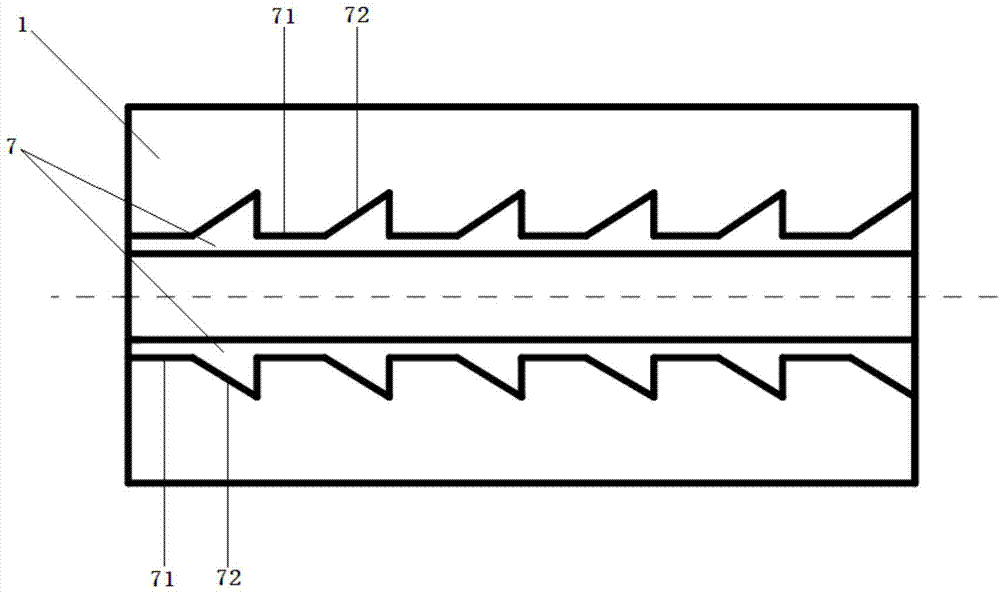

[0030] The inner shaft 1 is connected to the outer shaft 2 through a bearing 5, and an accommodating cavity 6 is provided between the inner shaft 1 and the outer shaft 2 for accommodating the permanent magnet rotor 3 and the magnetic permeable rotor 4; the permanent magnet rotor The quantity ratio of 3 and magnetic permeable rotor 4 is 1:2, and they are evenly spaced; the inner shaft 1 is connected to the permanent magnet rotor 3, and the circumferential surface of the inner shaft 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com