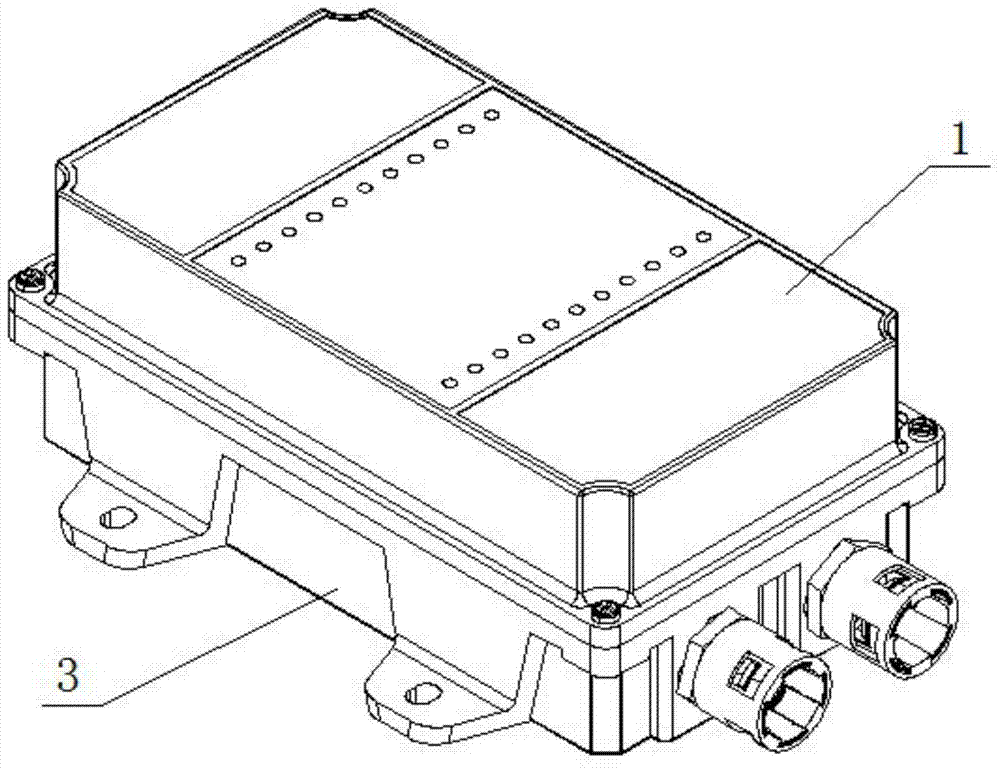

Waterproof and dustproof electric control box cooling structure

A waterproof, dust-proof, heat-dissipating structure technology, applied in cooling/ventilation/heating transformation, sealed enclosures, etc., can solve the problems of obstructing the discharge of hot air, unsatisfactory heat dissipation effect, and difficult to discharge hot air, to improve reliability, Good heat dissipation effect and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

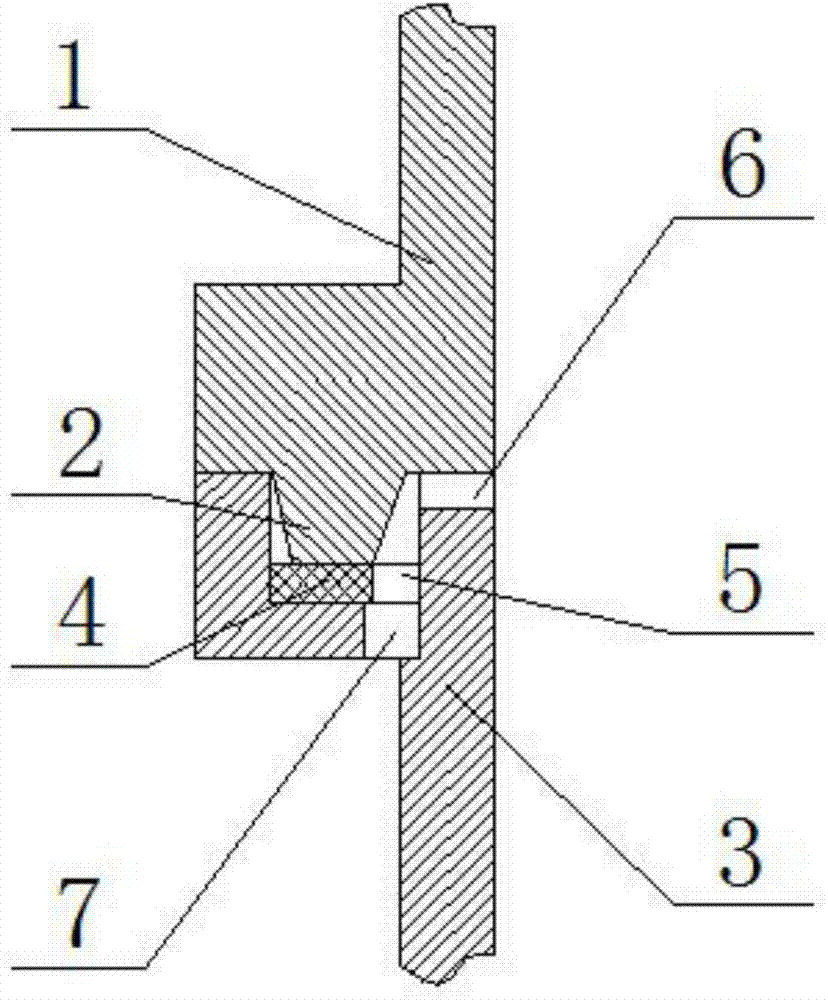

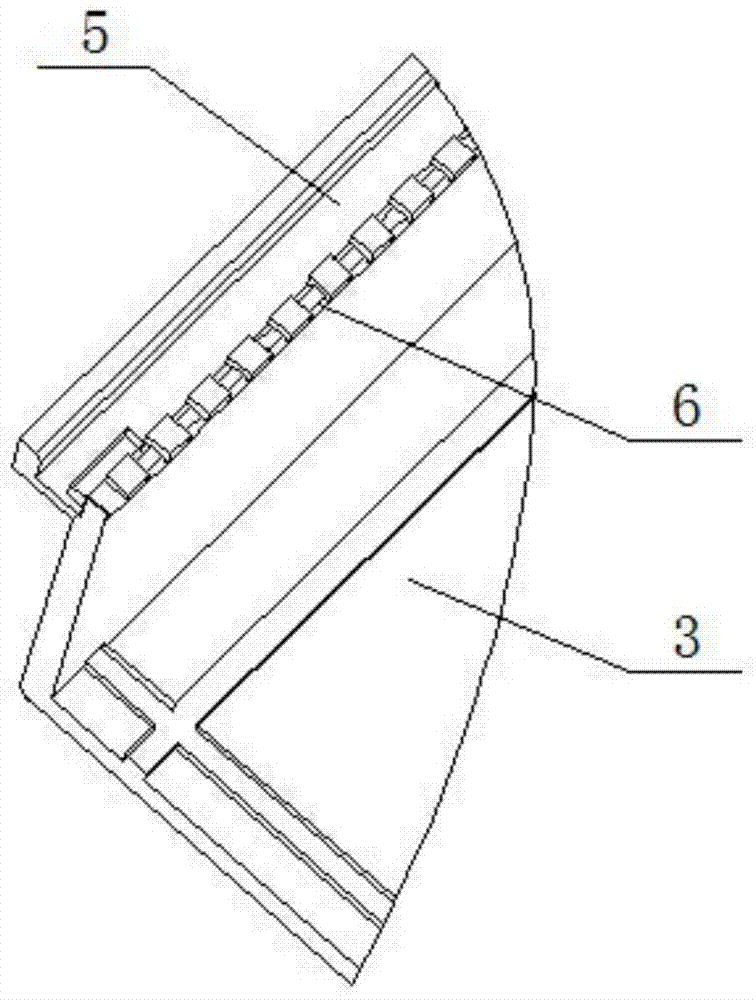

[0025] When the box cover 1 is closely matched with the box bottom 3, the internal temperature of the control box will rise due to the working environment or load. At this time, if Figure 6 , Figure 7 As shown, the internal heat of the box body enters the gap between the inner side of the boss 2 and the inner wall of the sealing groove 5 through the cooling hole 6, and then passes through the exhaust groove at the bottom of the sealing groove 5 under the guidance of the inclined surface of the inner side of the boss 2. Groove 8 and exhaust hole 7 are discharged to the outside of the control box, which makes it easier to discharge the internal heat of the product, adjusts the internal temperature of the product more efficiently, plays a good heat dissipation effect, and ensures the timely heat dissipation of the internal components of the product, thereby ensuring The product quality is improved, and the service life of the product is improved; after the box body is assembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com