Fixture for Automatic Positioning of Axial Holes of Shaft Parts

A technology for automatic positioning and shaft parts, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve problems such as easy loosening and difficult positioning of bolts, and achieve the effects of improving quality, eliminating front-end vibration, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

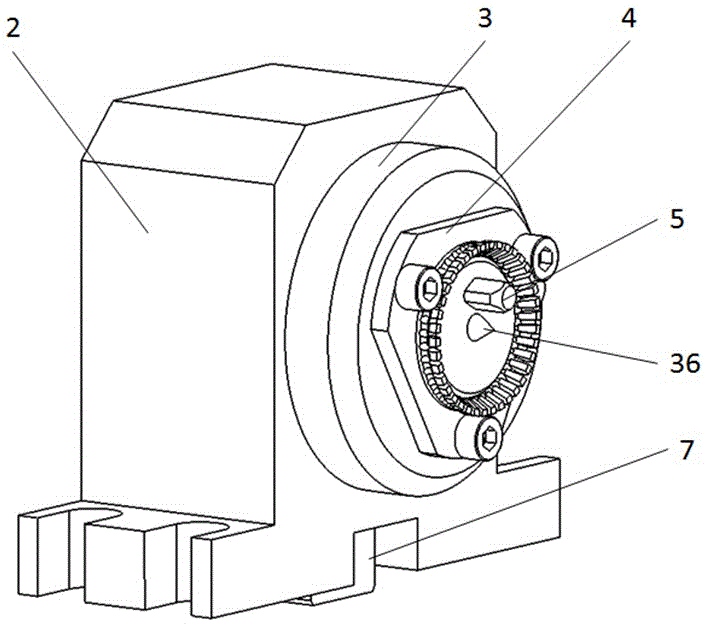

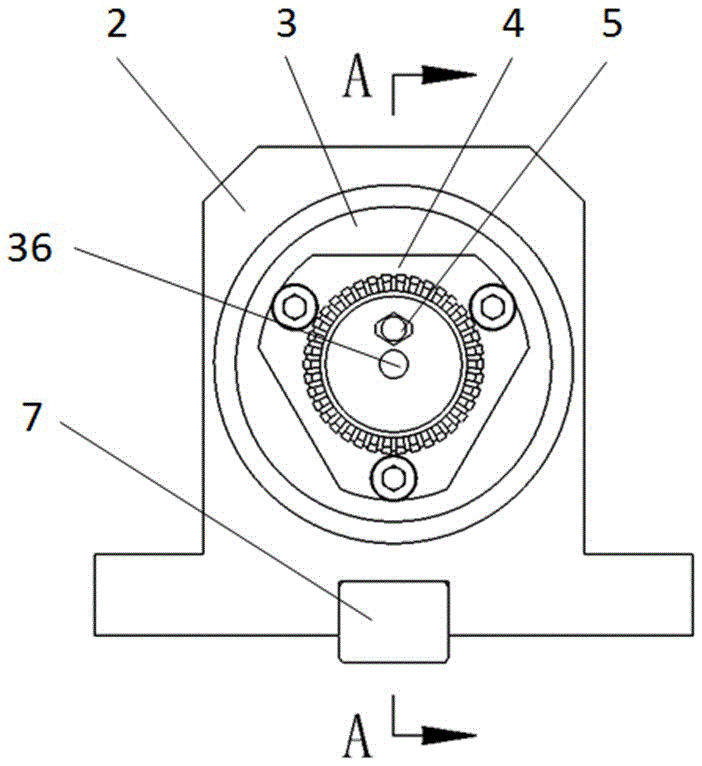

[0035] see figure 1 , a fixture for automatic positioning of axial holes of shaft parts, including a front positioning clamping mechanism, a tail clamping mechanism, more than one middle V-shaped block 6 and a bottom plate 1;

[0036] The bottom plate 1 is a rectangular plate, the middle part of which is provided with a positioning groove 12 along the length direction; the front positioning clamping mechanism and the tail clamping mechanism are respectively fixed at the two ends of the bottom plate 1 in the length direction, and more than one middle V-shaped block 6 is fixed on the middle part of the bottom plate 1;

[0037] The front positioning clamping mechanism includes a baffle plate 2, a baffle plate thimble 3 and a bushing 4;

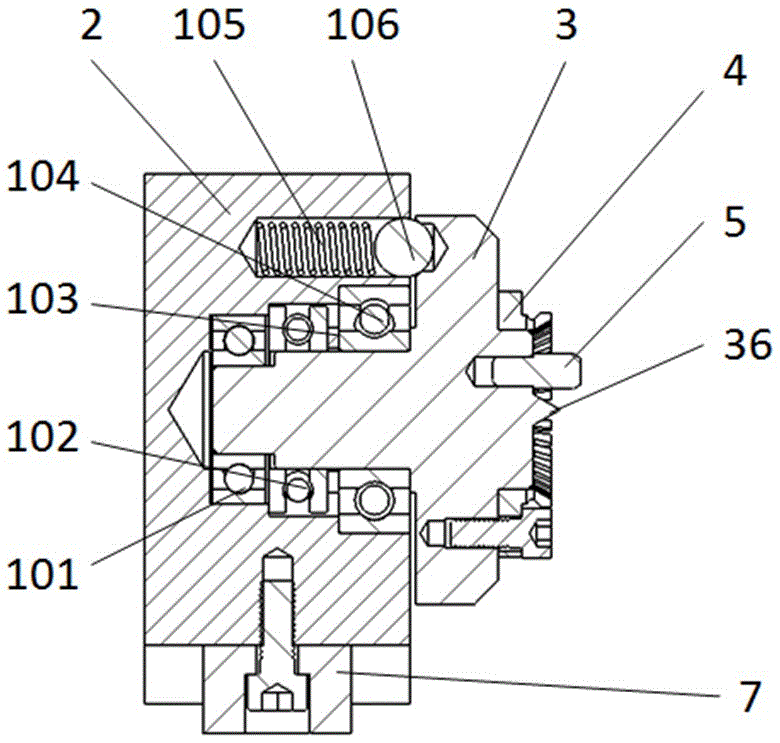

[0038] see Figure 5 , the baffle plate 2 is in the shape of a rectangular block, the middle part of the inner end surface is horizontally recessed with a rotary hole 23, the rotary hole 23 is a stepped hole, the top of the inner end surface is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com