Disc cutting device

A technology for cutting devices and discs, applied in printing devices, printing, etc., can solve the problems of waste of cutting processing time, large movement of the circular knife, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the disk cutting device according to this embodiment will be described in detail with reference to the drawings. In addition, the embodiment described below is only an example of this invention, As long as the structure of each part can achieve the object of this invention, it cannot be overemphasized that it can change or amend suitably within the range.

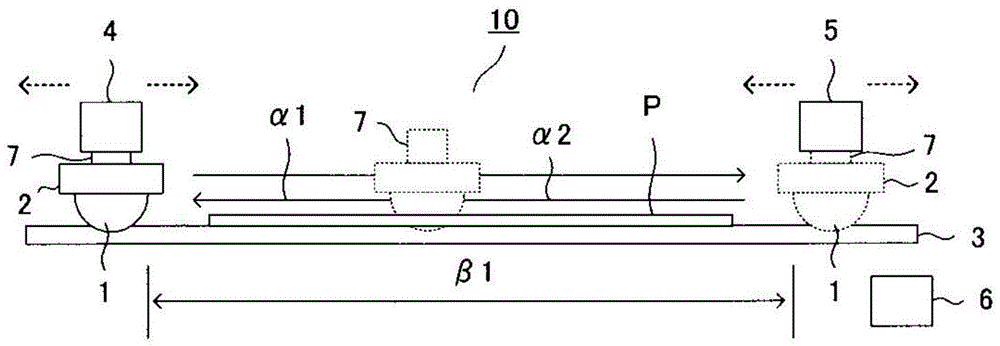

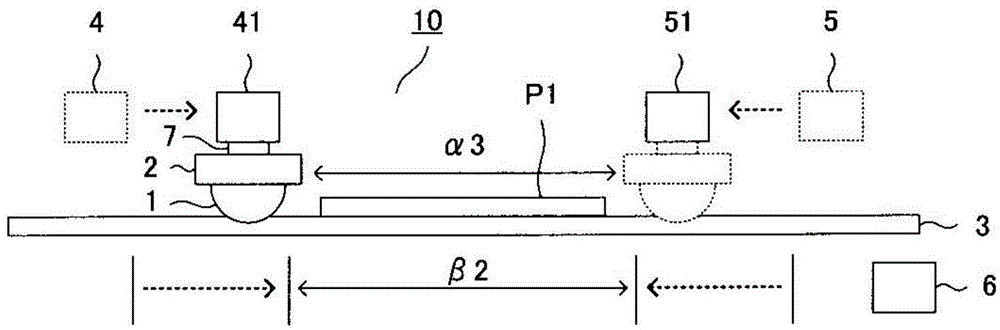

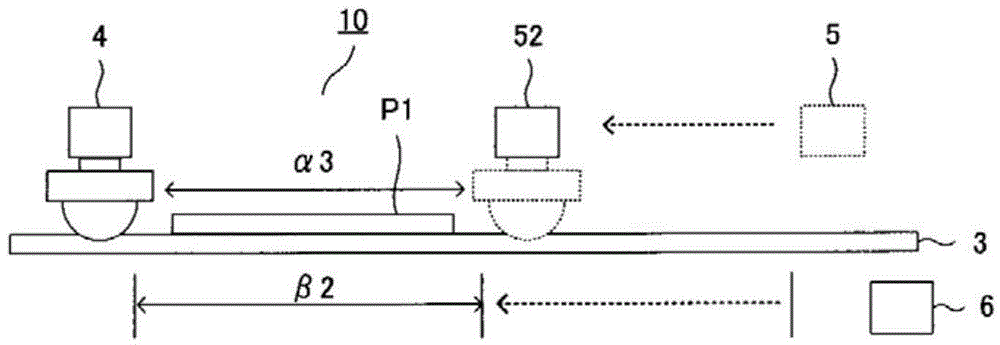

[0024] figure 1 is a schematic configuration diagram of a disk cutting device according to this embodiment, figure 2 Yes means applicable to figure 1 Diagram of the disc cutting device in the case of narrow-width media P1, image 3 is to indicate that the figure 2 The diagram of the disc cutting device in which the printing reference in is set to one side.

[0025] The disc cutting device (disc cutter device) related to this embodiment is used in thermal duplication and thermal printers having a thermal head for printing labels or price tag A device that cuts the medium P into a specified length.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com