Clamping plate type anti-shearing lock of electric vehicle

An electric vehicle and anti-shear technology, applied in padlocks, building locks, bicycle accessories, etc., can solve the problems of limited anti-theft function, high cost and high processing difficulty, and achieve lower production matching accuracy, lower production costs, and convenient production and processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] Specific embodiments: (the present embodiment does not have limitative effect to claim, is only a part of many embodiments, is not the whole content of claim)

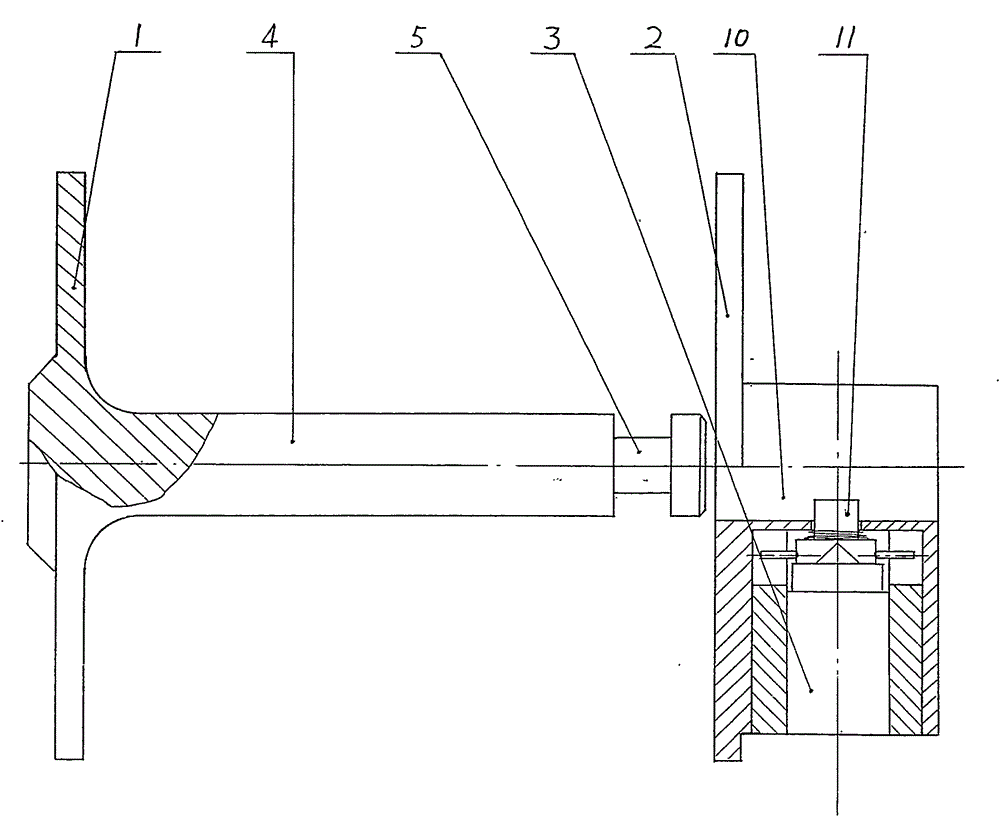

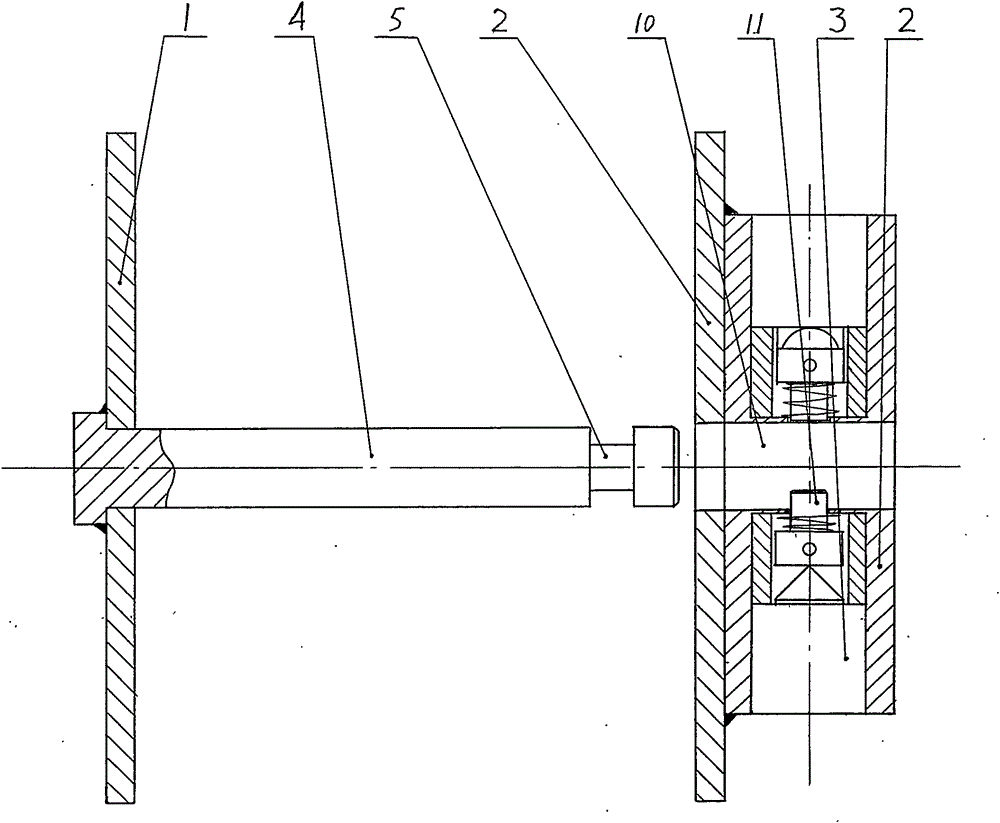

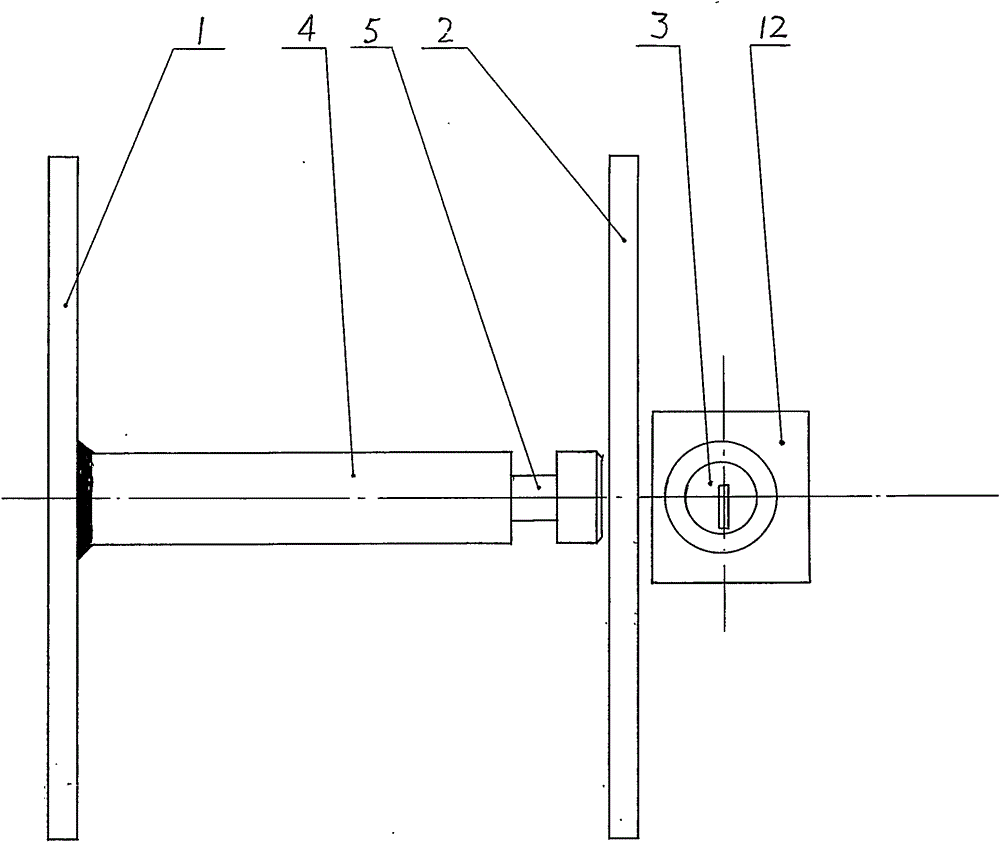

[0036] Specific embodiments of the present invention are as figure 1 Shown: the present invention is mainly made up of lock bar frame 1, lock seat frame 2, lock head 3, is characterized in that: lock bar frame 1 is provided with one or several lock bars 4, and the other end of lock bar 4 is provided with for The groove 5 or concave hole that deadbolt snaps in or is provided with the deadbolt 6 that lock head 3 drives, perhaps lock rod frame 1 is provided with one or several through holes 7 for the lock rod to insert, and one end of lock rod 4 is provided with There is a lock cap 8 that is larger than the size of the lock bar and the other end is provided with a groove 5 or a concave hole for the lock tongue to snap in or is provided with a lock tongue 6 driven by the lock head 3, or the lock bar frame 1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com