Pot type water purifying machine and water purifying machine system

A water purifier and pot-type technology, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc. It can solve the problems of large space occupation, difficult production, water leakage, etc. , to achieve the effect of joint pipeline reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in detail below in conjunction with the drawings.

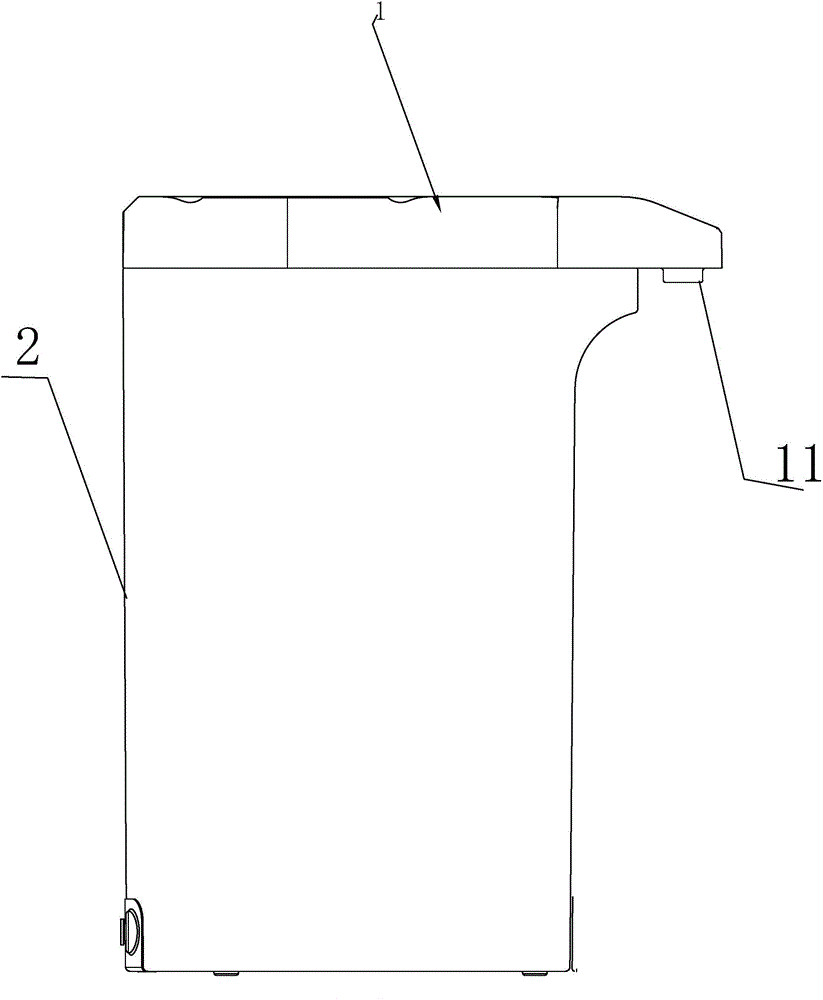

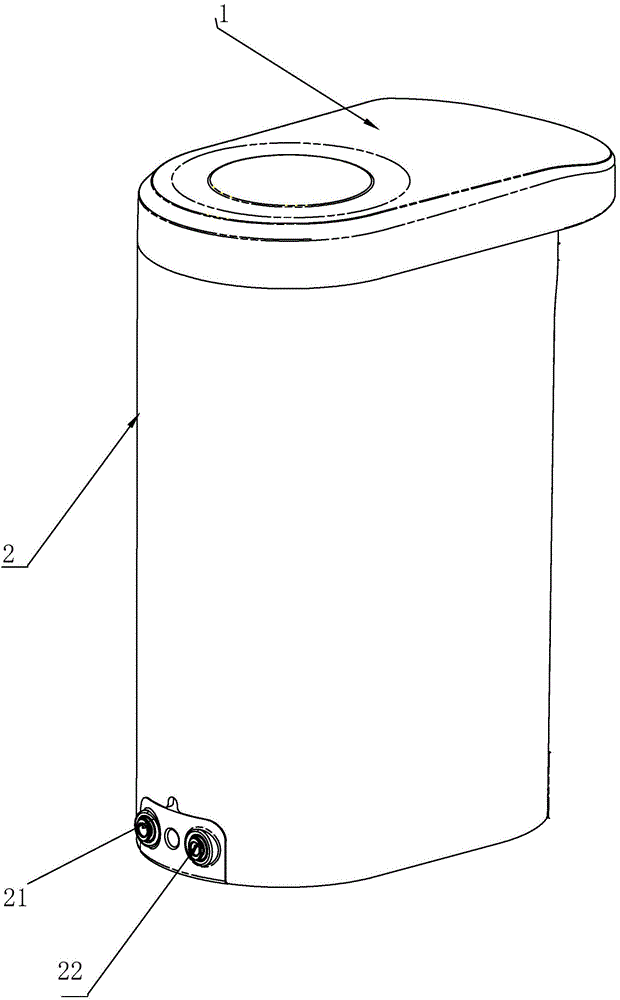

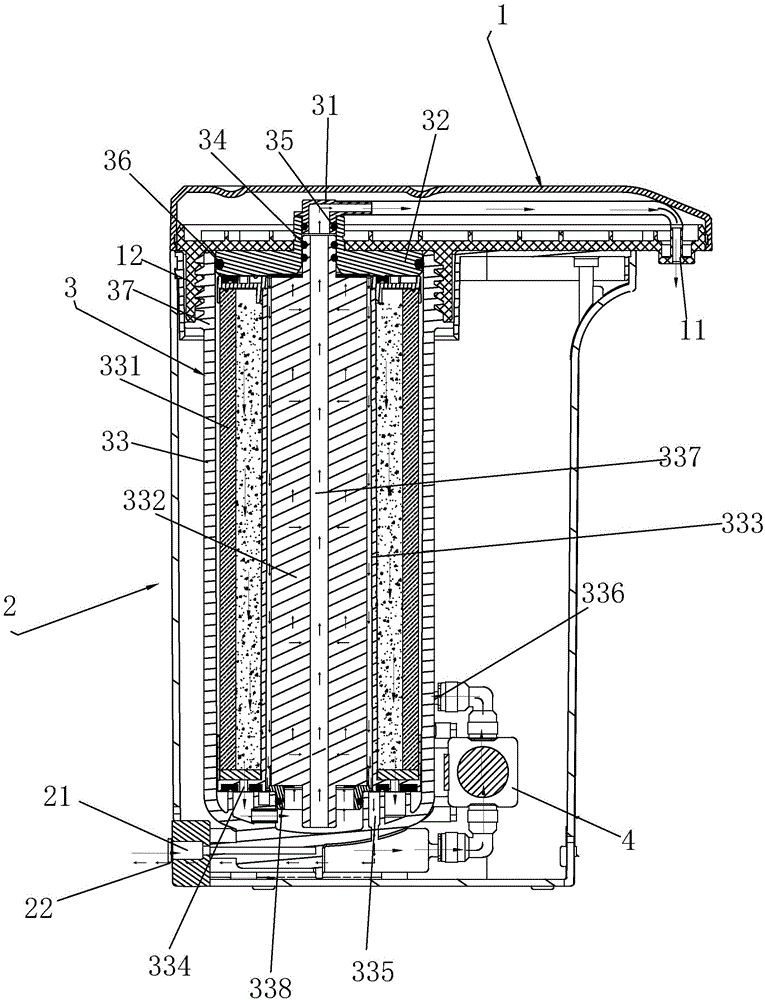

[0024] See figure 1 , figure 2 and image 3 , the pot-type water purifier of the present invention comprises a machine cover 1, a main casing 2, a composite filter cartridge structure 3 and an automatic water cut-off device 4, and the machine cover 1 comprises a water purification port 11, a first connecting structure (not shown) and a second The connecting structure 12, the main casing 2 includes a third connecting structure (not shown) arranged on its top, the main casing 2 further includes a water inlet 21 and a sewage outlet 22 arranged on its side wall near the bottom, the first connecting structure and The third connection structure is used to realize the connection between the main casing 2 and the cover 1, preferably the first connection structure and the third connection structure are movably connected.

[0025] In this embodiment, the compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com