Inner fork chute type axially sliding constant-velocity-ratio universal joint

An inner fork slideway type, constant velocity universal joint technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problem of affecting product assembly clearance, performance and efficiency, poor anti-centrifugal and anti-deformation effects, Increase raw material consumables and other issues to achieve good assembly effect, low cost, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention are now described in detail in conjunction with the accompanying drawings:

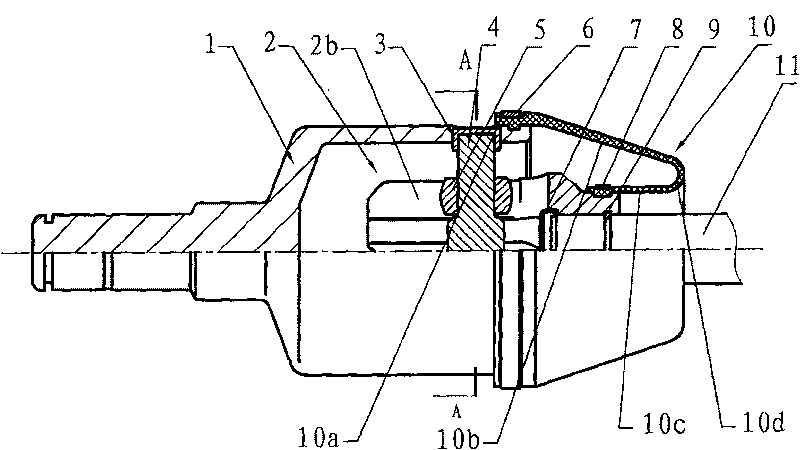

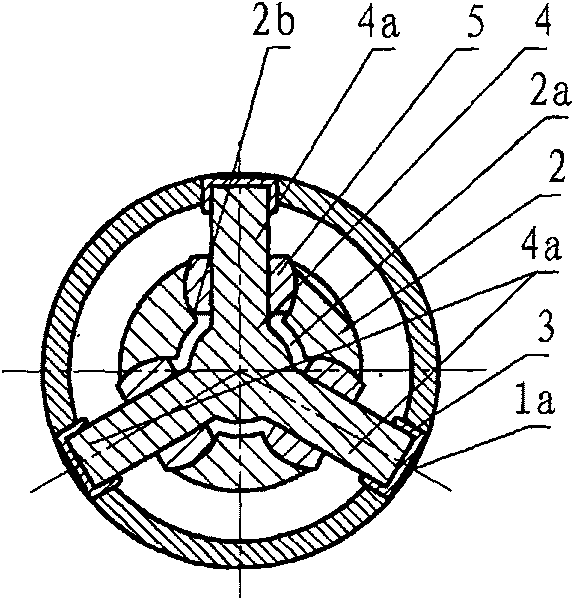

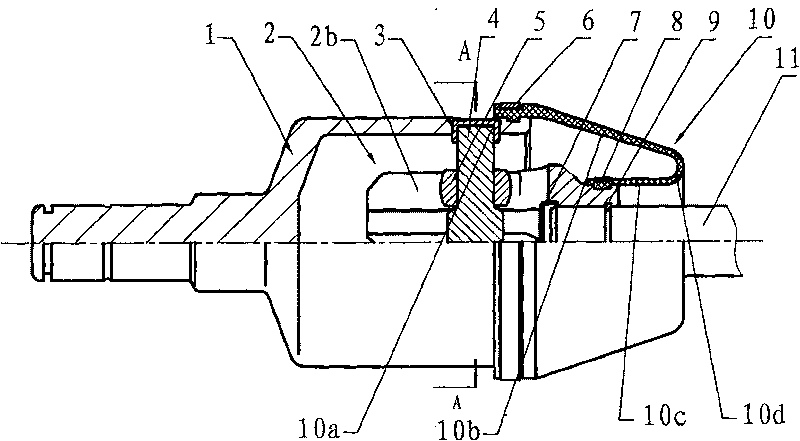

[0012] Such as figure 1 , figure 2 As shown, an embodiment of an inner fork slideway type constant velocity universal joint that can slide axially in the present invention includes a housing 1 and a three-pin frame 4 , each leg of which is slidably sleeved on the three-pin frame 4 The ball ring 5 on the shaft 4a, the ball lane and the dust cover 10 matched with the ball ring 5 also include a three-pointed joint 2, and the three-pointed joint 2 is uniformly distributed in the circumferential direction with three ballways 2b (uniformly distributed in the circumferential direction refers to three ballways). 2b is distributed in three equal parts on the circumference of the trident), the axis is provided with a member with a central hole 2a, the trident 2 is fixed on one end of the intermediate shaft 11, and the central hole 2a communicates with the three ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com