A homogeneous valve group

A homogeneous valve and valve core technology, which is applied in grain processing, peptides, organic chemistry, etc., can solve the problems of unprocessable, fragile, and high brittleness, and achieve convenient preparation, high reproducibility, and good product stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

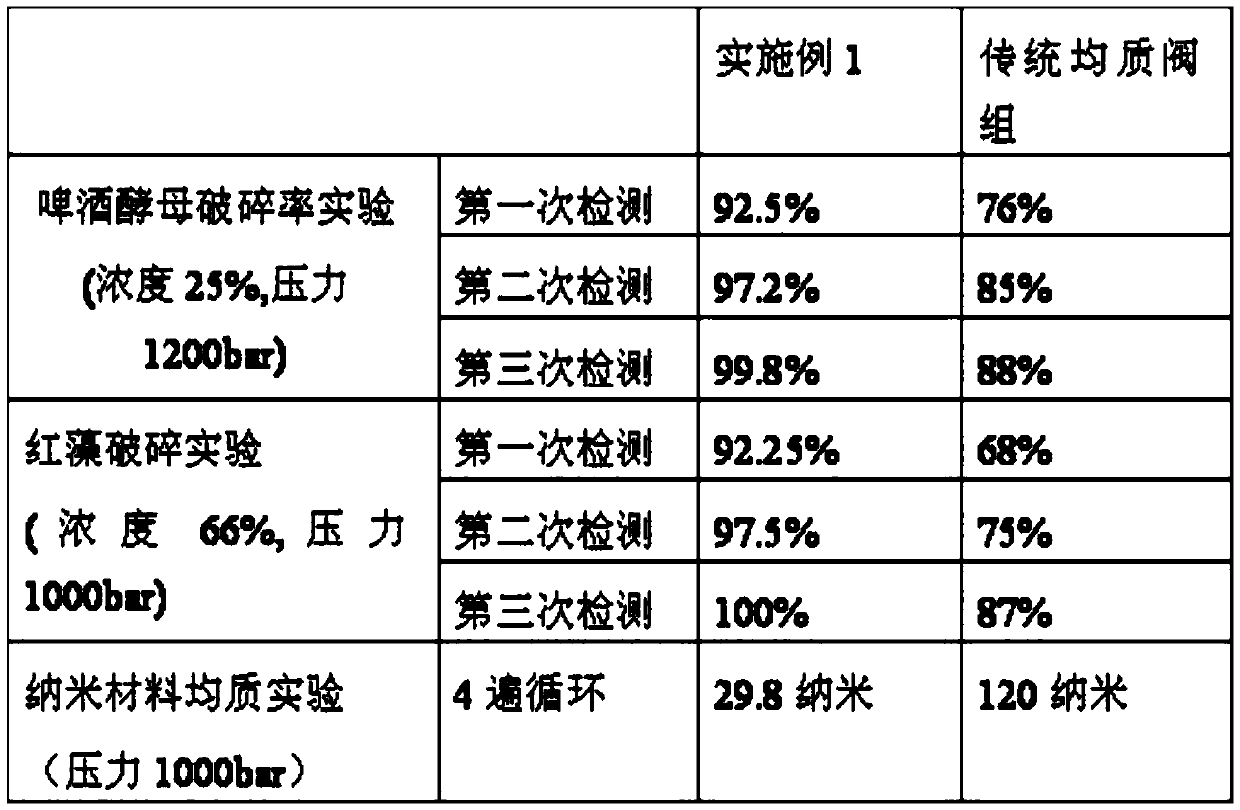

Embodiment 1

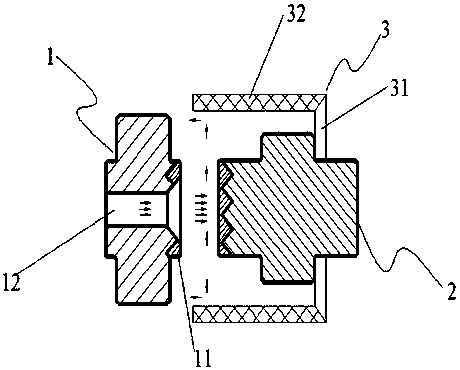

[0015] A homogeneous valve group, including a diamond valve seat 1, a diamond valve core 2 and a retaining ring 3, the diamond valve seat 1 is provided with a bump 11, and the bump 11 is provided with a flow limiting gap 12, the diamond valve The core 2 is a cylinder, and its end faces the flow-limiting slit 12 , and the end of the flow-limiting slit 12 facing the end face of the diamond spool 2 is bell-mouthed. Wherein, the retaining ring 3 includes a root portion 31 and an end portion 32; its root portion 31 is fixed on the outer edge of the diamond spool 2, and its end portion 32 protrudes beyond the end surface of the diamond spool 2 to form a joint with the bump 11 and the diamond spool 2. Collision ring. In practice, the material is ejected from the flow-limiting slit 12 and hits the end surface of the diamond spool 2 to generate a first right-angle shear. After changing the direction of movement, it hits the end 32 to generate a second right-angle shear and splashes out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com