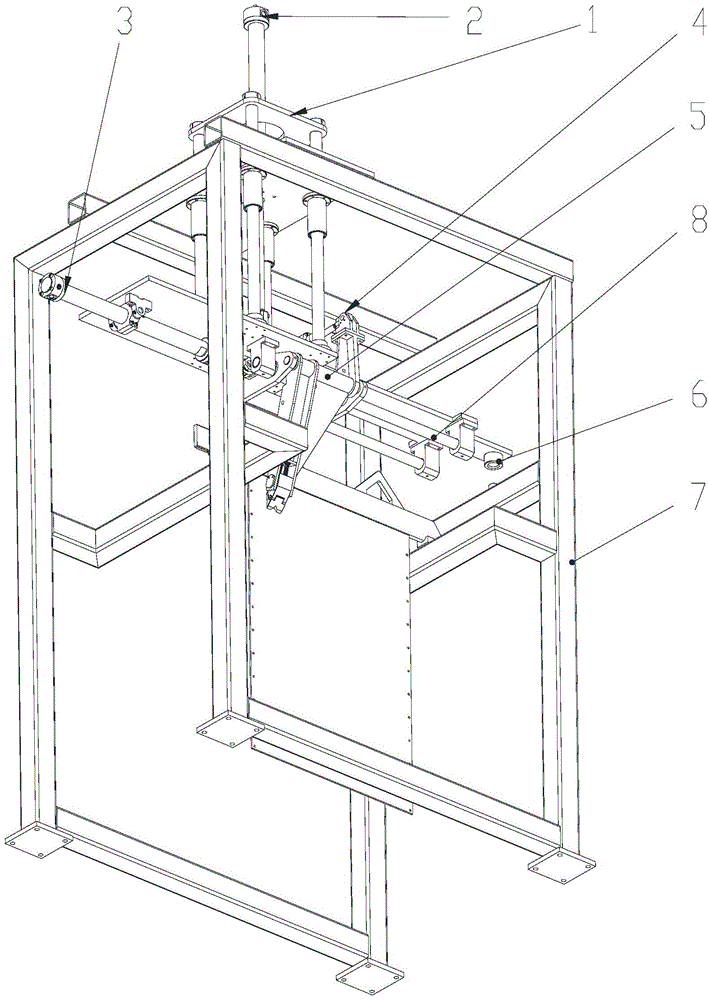

Cathode zinc plate pre-stripping device

A pre-stripping, cathode zinc technology, applied in the direction of photography technology, instruments, photography auxiliary technology, etc., can solve the problems such as time-consuming and laborious manual chisel, high production cost, unfavorable opening, etc., to achieve simple and reliable structure and reduce noise on production site. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

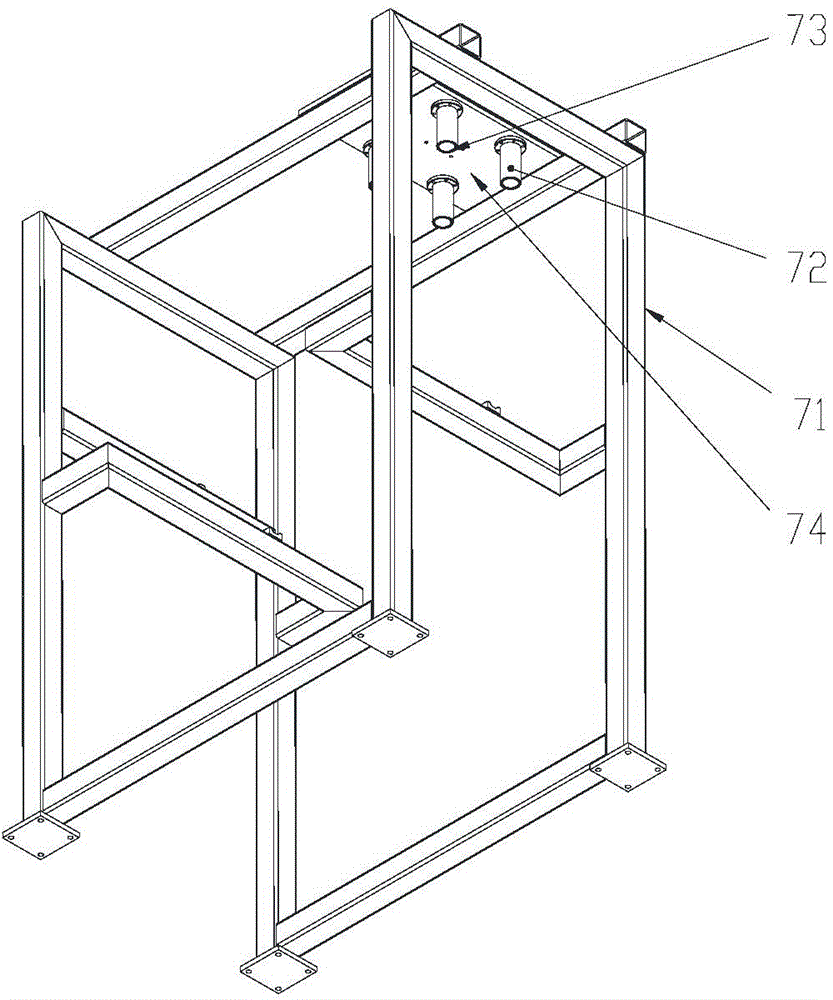

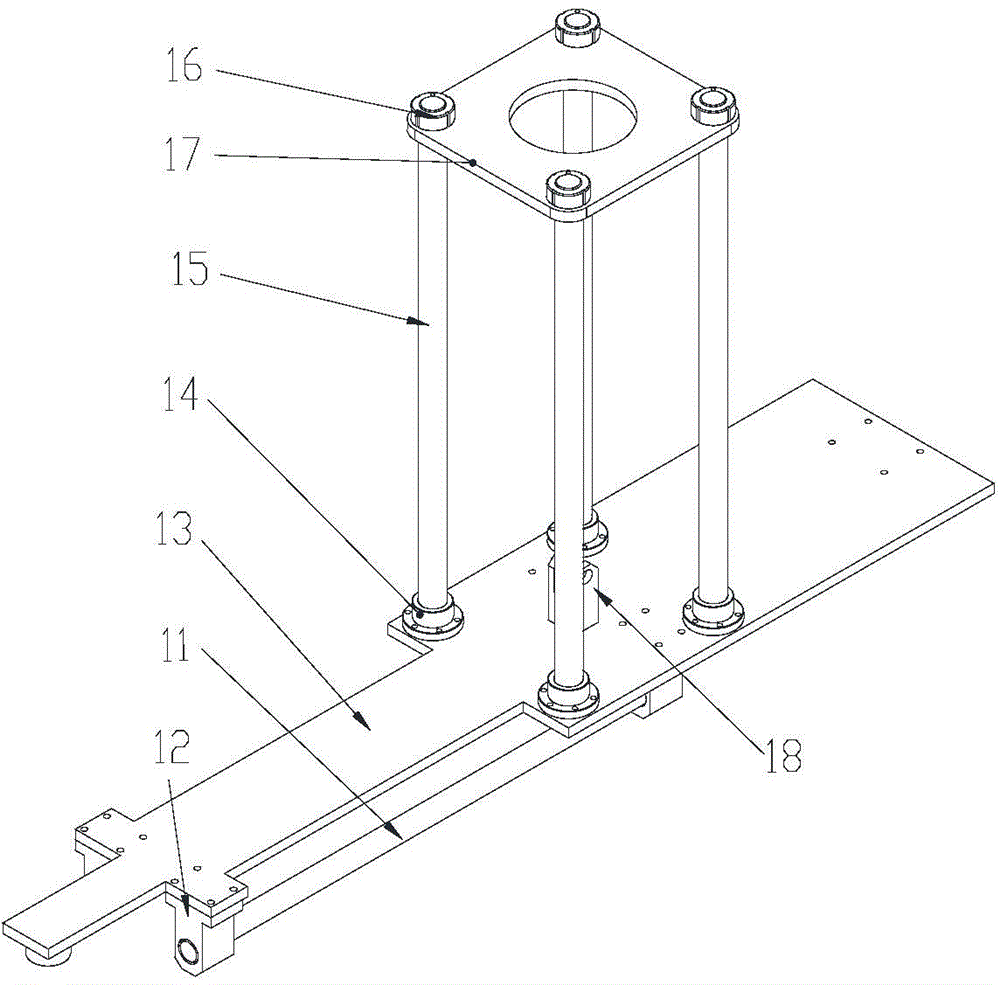

[0014] The present invention will be described in detail below in conjunction with accompanying drawing: Figures 1 to 4 As shown, the present invention comprises frame 7, up and down sliding four-column frame 1, pocket knife swing arm mechanism 5 and peeling knife frame 8, and described up and down sliding four-column frame 1 includes four guide posts 15 that are equally distributed, two Symmetrically distributed horizontal guide posts 11, moving plates 13 and hinge points 18, the frame 7 includes four guide sleeves 72 equally distributed, and the four-post frame 1 that slides up and down passes through the four guide posts 15 It is connected with the four guide sleeves 72 in the frame 7, and is hingedly connected with the hinge point 18 provided on the moving plate 13 through the four-column drive cylinder 2; the stripping knife frame 8 includes two symmetrically distributed Stripping sliding frame 81, first shaft pin 82, this stripping knife frame 8 is connected with the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com