Timing signal fault diagnosis device for electronic control internal combustion engine

An internal combustion engine, engine technology, applied in the direction of internal combustion piston engine, combustion engine, engine control, etc., can solve problems such as lack of availability and inability of the engine to run

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Timing Signal Failure Detection Mode

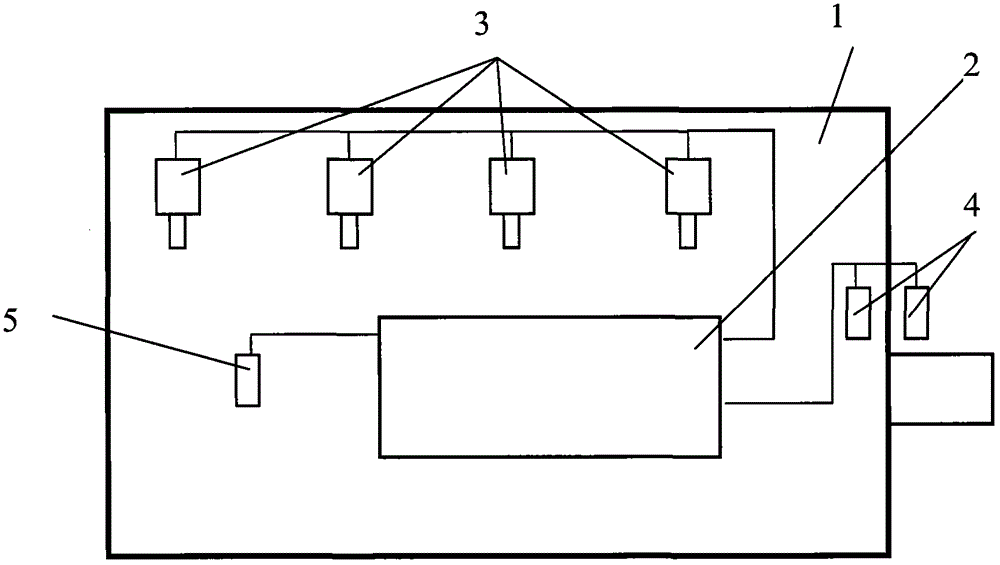

[0051] An EFI engine 1 can still run. The ECU fault code indicates a failure of one timing signal.

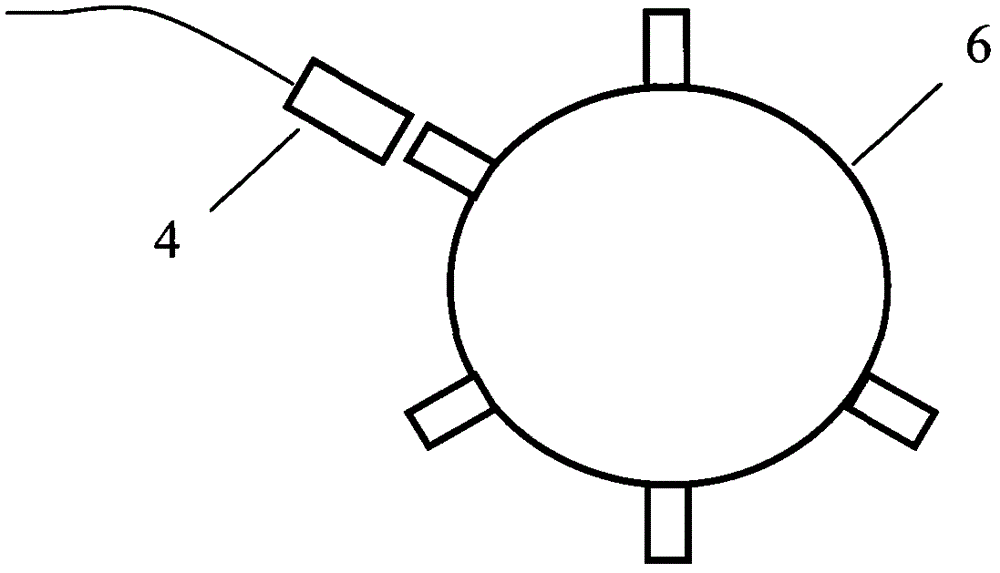

[0052] Connect two timing sensors 4 of engine, engine ECU2 and two timing signal input terminals 14 of the present invention with two three-way cables. Like this engine ECU2 and the present invention 9 can detect the signal of 2 road timing sensors 4 simultaneously.

[0053] Select the model of the engine to be tested through the user interface 13 . The central processing unit 11 reads in the corresponding timing signal characteristic parameters in the database 12 .

[0054] Start the engine, steady at idle. The start of detection of the timing signal is instructed through the user interface 13 .

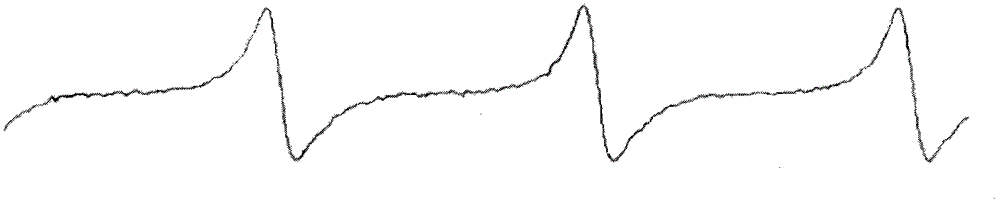

[0055] The input timing signal 14 becomes a square wave signal through the shaping circuit 16, and the identification input timing signal module 17 identifies the two-way timing square-wave signal to generate two time sequences bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com