Bypass passive double-throat vectoring nozzle with reverse thrust function

A vector nozzle and double-throat technology, applied in the field of bypass passive double-throat vector nozzle, can solve the problems of poor reliability, high cost, rare and other problems, and achieve the effect of improving reliability and reducing structural weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

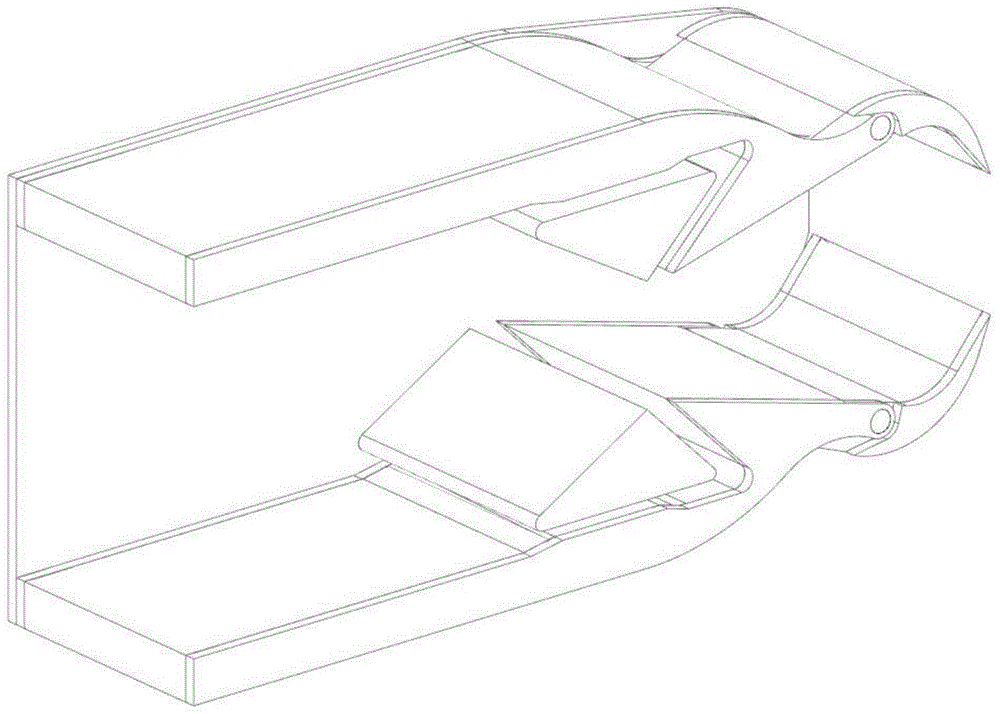

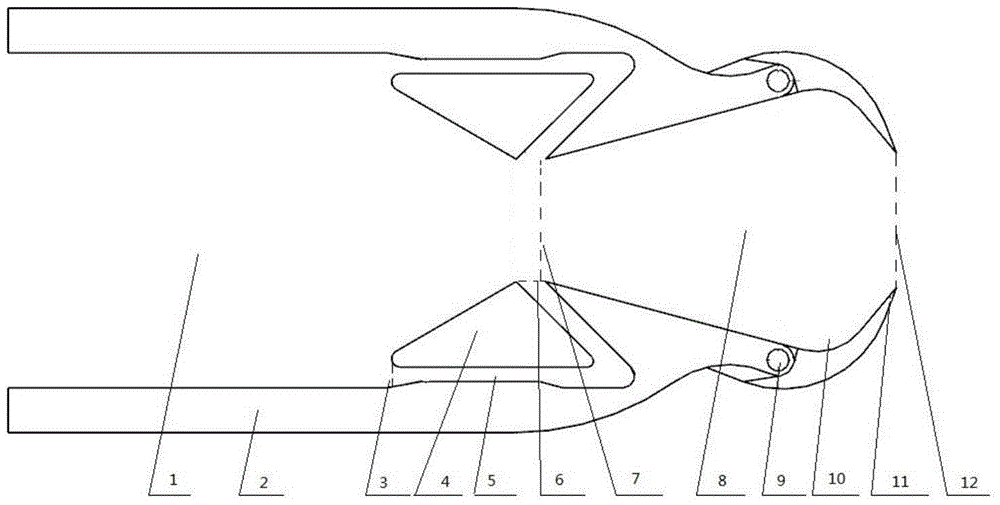

[0028] like figure 1 As shown, the bypass passive dual-throat vectoring nozzle with reverse thrust function disclosed in this embodiment, compared with the bypassing passive dual-throat vectoring nozzle in the prior art, mainly lies in Give the nozzle a reverse thrust function.

[0029] In the prior art, the disclosed bypass type passive double-throat vector nozzle includes a nozzle body, and the inner flow path of the nozzle body includes a converging section 1 at the front of the throat, a throat 7, The expansion and convergence section 8 at the front of the second throat 12, the throat cavity 10 and the second throat 12, the convergence section 1 at the front of the throat is provided with a bypass passage 5 next to a throat 7, and the entrance of the bypass passage 3 is set facing the fluid inlet of the inner flow channel of the nozzle body, and the outlet 6 of the bypass channel is located at the first throat 7; at the same time, the bypass channel 5 passes through the b...

Embodiment 2

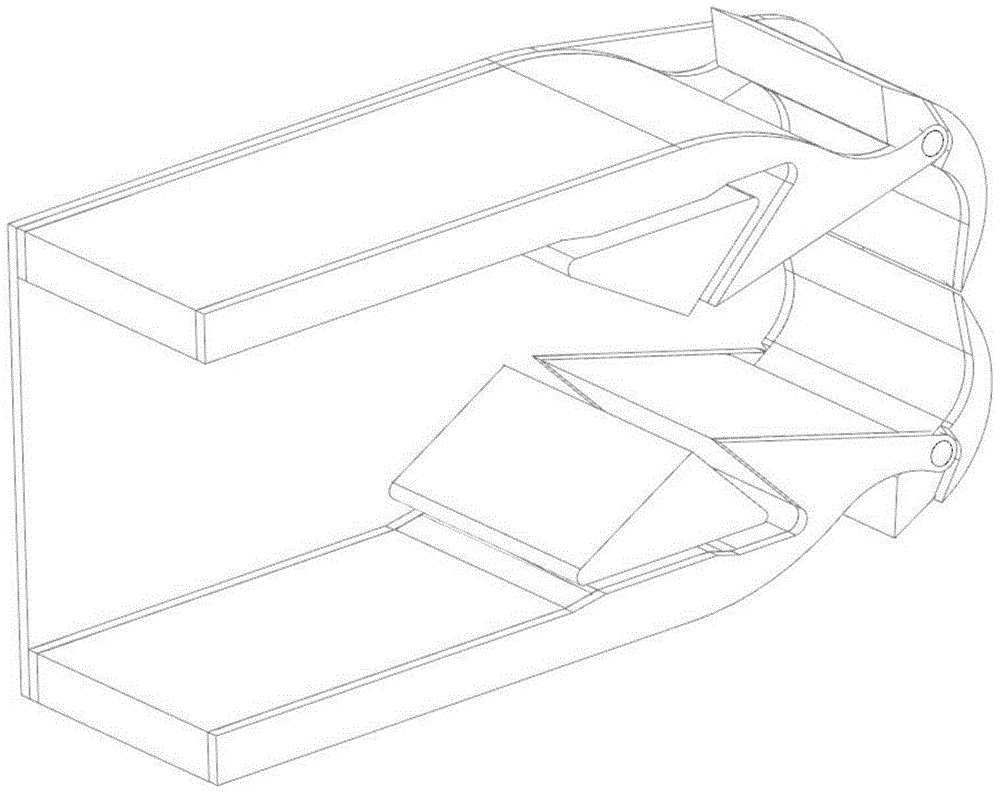

[0035] The technical solution disclosed in this embodiment is generally consistent with that of Embodiment 1, which is a further improvement of the embodiment. In this embodiment, the structure of the anti-thrust formation part is specifically disclosed: the outer surface of the rotating shaft support 2 of the rear body of the nozzle close to the fixed end of the rotating shaft is set as a concave arc surface, and the concave arc surface and the two throats The internal profiles of the expansion and convergence section 8 at the front part are smoothly connected; thus, when the air flow escapes from the reverse thrust airflow channel formed between the nozzle rear body and the nozzle rear body shaft support 2, it can be opposite to the slope surface. Thrust is generated, which is opposite to the thrust generated by the fluid in the nozzle body, and has the effect of reducing the flow velocity of the aircraft.

Embodiment 3

[0037] The technical solution disclosed in this embodiment is generally consistent with that of Embodiment 1, which is a further improvement of the embodiment. In this embodiment, the rear body of the nozzle and the arrangement position of the shaft support 2 of the rear body of the nozzle are specifically disclosed. According to the applicant's multiple tests, the parameters with better anti-thrust effect are: the length from the rotating shaft to the outlet of the nozzle is 10%-85% of the expansion and convergence section 8 at the front of the second throat, and the rotating part at the tail mainly refers to Yes, the rotation angle of the upper plate and the lower plate of the rear body of the nozzle is 0°-120°.

[0038] In addition, the splicing position between the rear body of the nozzle and the shaft support 2 of the rear body of the nozzle is at the most extreme position: the inner cavity of the rear body of the nozzle is formed by the expansion and convergence section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com