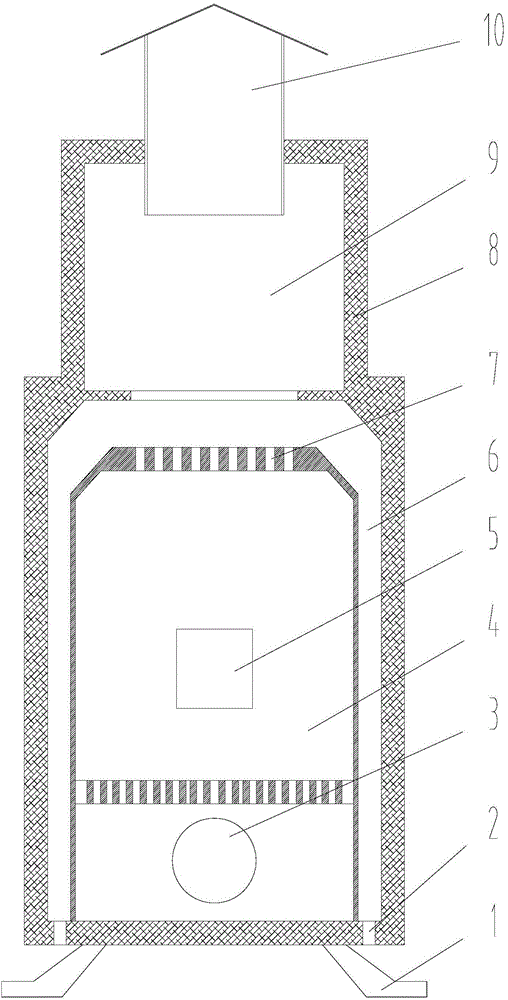

Incinerator

A technology for incinerators and combustion chambers, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as insufficient combustion, achieve the effects of low content of harmful substances in flue gas, simplified structure, and reduced use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Plastic extruders require a metal filter and these need to be replaced frequently. A lot of plastics are adhered to the surface of the used filter screen, and the present invention is used to incinerate the used filter screen. Put the used filter screen into the primary combustion chamber of the present invention for incineration, and control the temperature in the primary combustion chamber to be 500-600°C by adjusting the size of the primary combustion air inlet; control the secondary combustion by adjusting the size of the secondary combustion air inlet The indoor temperature is 900-1100°C.

[0029] Measured by an infrared thermometer, the temperature in the primary combustion chamber is 600°C, and the temperature in the secondary combustion chamber is 1100°C. The used filter screen is burned in the primary combustion chamber, and the plastic attached to it is burned and removed. The pyrolysis gas and particles produced by the combustion enter the secondary combusti...

Embodiment 2

[0032] Waste wires contain copper cores. If the copper cores are recovered by manually stripping the wire sheath, the efficiency is low and the labor cost is high. Use the present invention to incinerate waste and old electric wires, put the waste and old electric wires into the primary combustion chamber of the present invention for incineration, and control the temperature in the primary combustion chamber to be 500-600°C by adjusting the size of the primary combustion air inlet; by adjusting the size of the secondary combustion air inlet, Control the temperature in the secondary combustion chamber to be 900-1100°C.

[0033] Measured by an infrared thermometer, the temperature in the primary combustion chamber is 580°C, and the temperature in the secondary combustion chamber is 1000°C. The waste wires are burned in the primary combustion chamber, and the sheath on them is burned and removed. The cracked gas and particles produced by the combustion enter the secondary combust...

Embodiment 3

[0036] Disposal of leftovers of carbon fiber products. There is usually a layer of resin on the surface of carbon fiber products. To recycle carbon fiber, the resin layer on the surface must be removed. Using the present invention to incinerate the leftovers of carbon fiber products, put the leftovers of carbon fiber products into the primary combustion chamber of the present invention for incineration, by adjusting the size of the primary combustion air inlet, the temperature in the primary combustion chamber is controlled to be 500-600°C; by adjusting the secondary combustion air The size of the inlet controls the temperature in the secondary combustion chamber to be 900-1100°C.

[0037] Measured by an infrared thermometer, the temperature in the primary combustion chamber is 580°C, and the temperature in the secondary combustion chamber is 1000°C. The carbon fiber product waste is burned in the primary combustion chamber, and the outer resin layer is burned and removed. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com