Diffuser vane for a compressor device and diffuser assembly comprised thereof

A diffuser and compressor technology, applied in the field of compressor devices, can solve problems such as reducing the efficiency of variable diffuser guide vanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

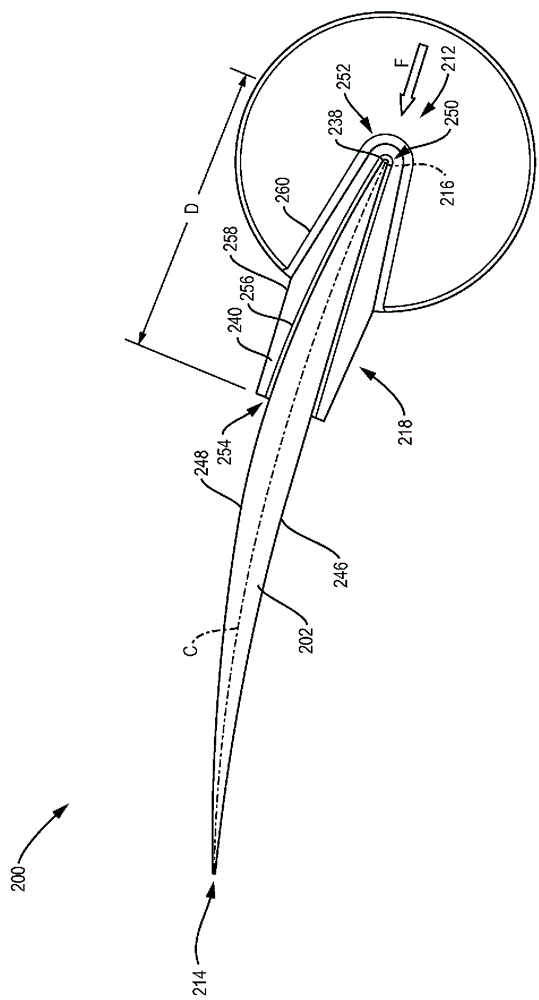

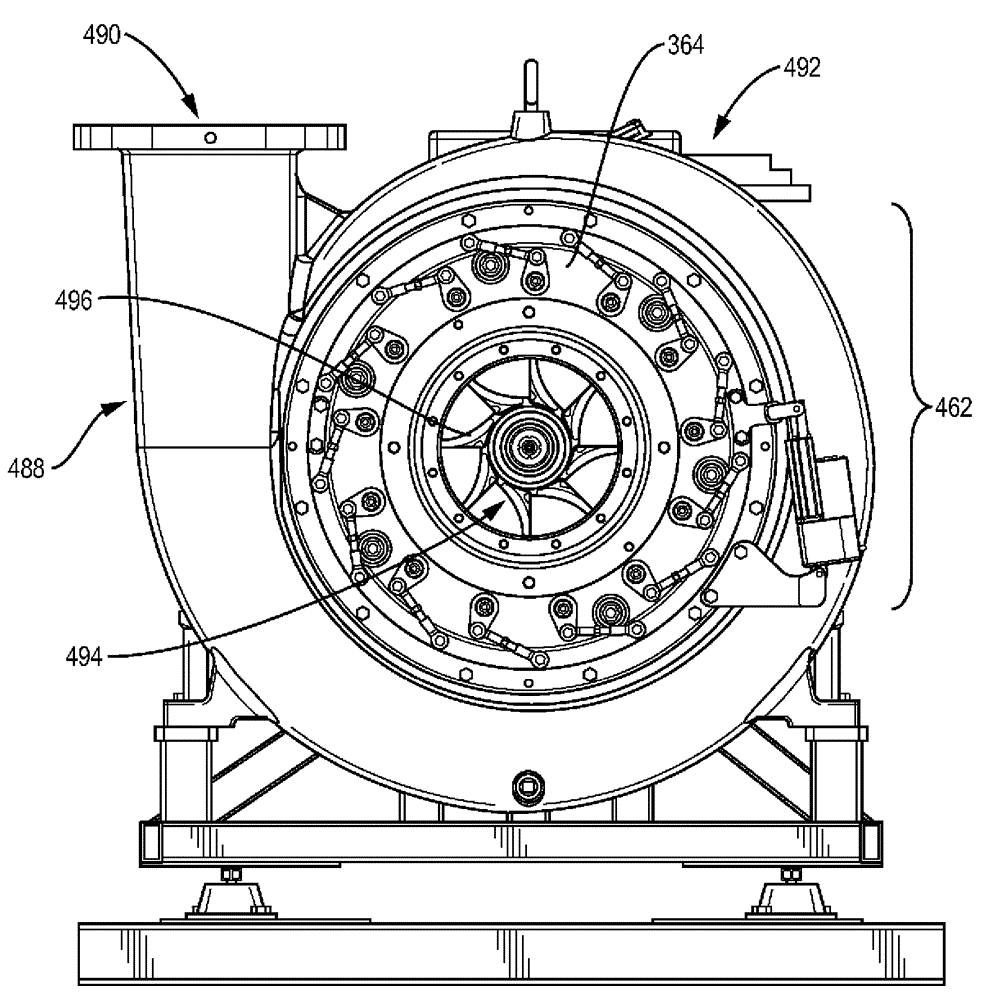

[0018] The following discussion focuses on the construction and implementation of diffuser guide vanes for better performance of compressor devices (eg centrifugal compressors). In one aspect, the design for the diffuser guide vanes allows the trailing edge to rotate to various angular positions while maintaining the orientation of the leading edge with respect to the flow direction of the working fluid flowing through the diffuser guide vanes to prevent flow separation. These designs also stabilize the diffuser vanes to prevent vibration of the diffuser vanes in response to excitation frequencies that can damage the diffuser vanes.

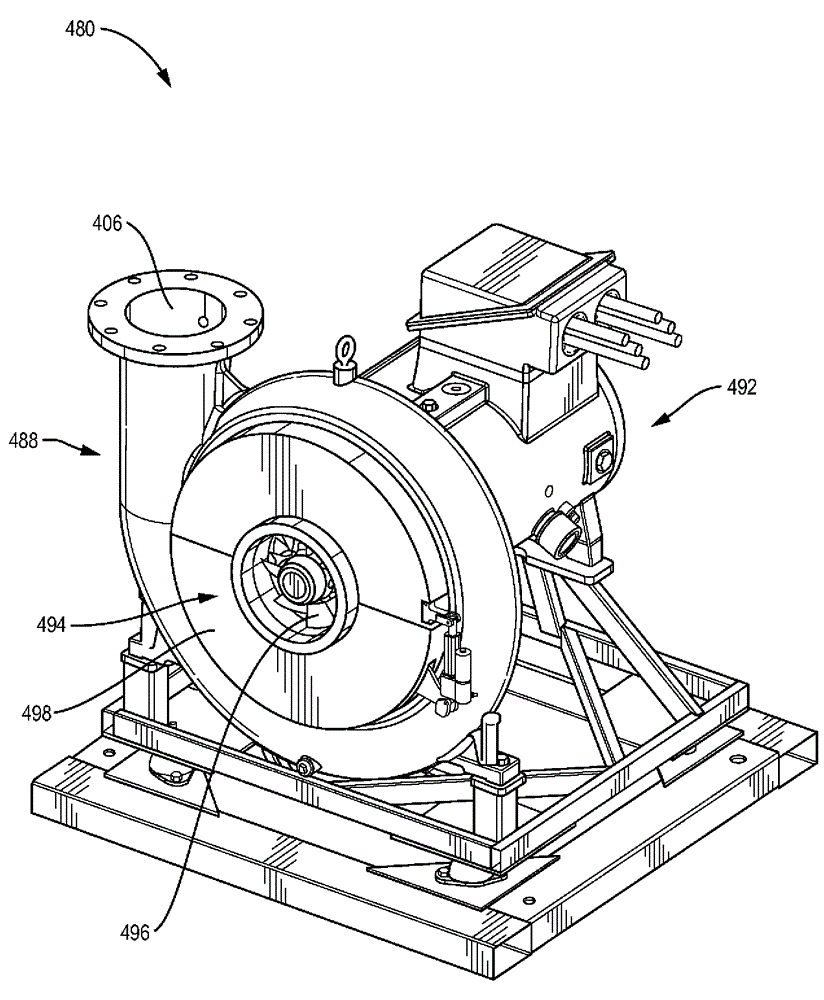

[0019] These diffuser vanes are utilized in a diffuser assembly whose operation can adjust the performance of the compressor. The diffuser assembly may include a plurality of diffuser vanes. In one example, the diffuser assembly couples the diffuser vanes to a conventional actuator to facilitate adjustment of the position of the trailing edge, for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com