A casing suitable for diameter expansion and deformation and its processing method

A casing and pipe body technology, applied in the field of oil and gas well construction and workover, can solve the problems of low connection strength, detachment of the sealing rubber ring, lack of sealing effect, etc., to increase the contact pressure, improve the sealing performance, improve the The effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

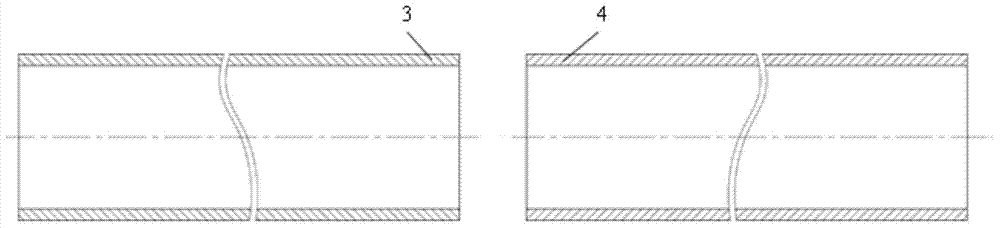

[0046] figure 1 It is two casing light pipes, one end of one sleeve light pipe is the external thread joint 4 of the present invention, and one end of the other sleeve light pipe is the internal thread joint 3 of the present invention. The length of the externally threaded joint 4 and the internally threaded joint 3 is about 200mm-300mm.

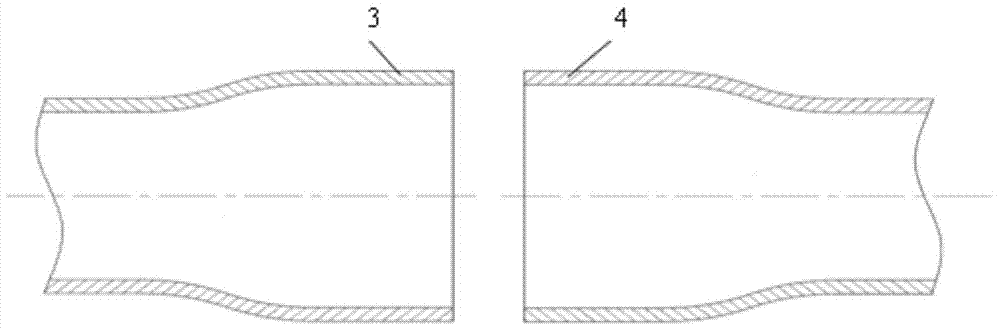

[0047] figure 2 In this method, the externally threaded joint 4 and the internally threaded joint 3 are respectively expanded by using the metal pipe diameter expanding method to increase the diameter by 20%-25%, and the diameter expansion deformation can be realized by cold deformation or hot deformation. After the diameter is expanded, the internal stress caused by the cold deformation of the metal is eliminated by normalizing or annealing heat treatment, and the structure is refined, and the mechanical properties are restored to the same level as the pipe body. The specific heat treatment system depends on the properties of the metal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com