A kind of silicon-carbon composite negative electrode material and its preparation method and application

A composite material, in-situ composite technology, applied in nanotechnology, silicon compounds, chemical instruments and methods for materials and surface science to improve capacity, improve conductivity, and avoid agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

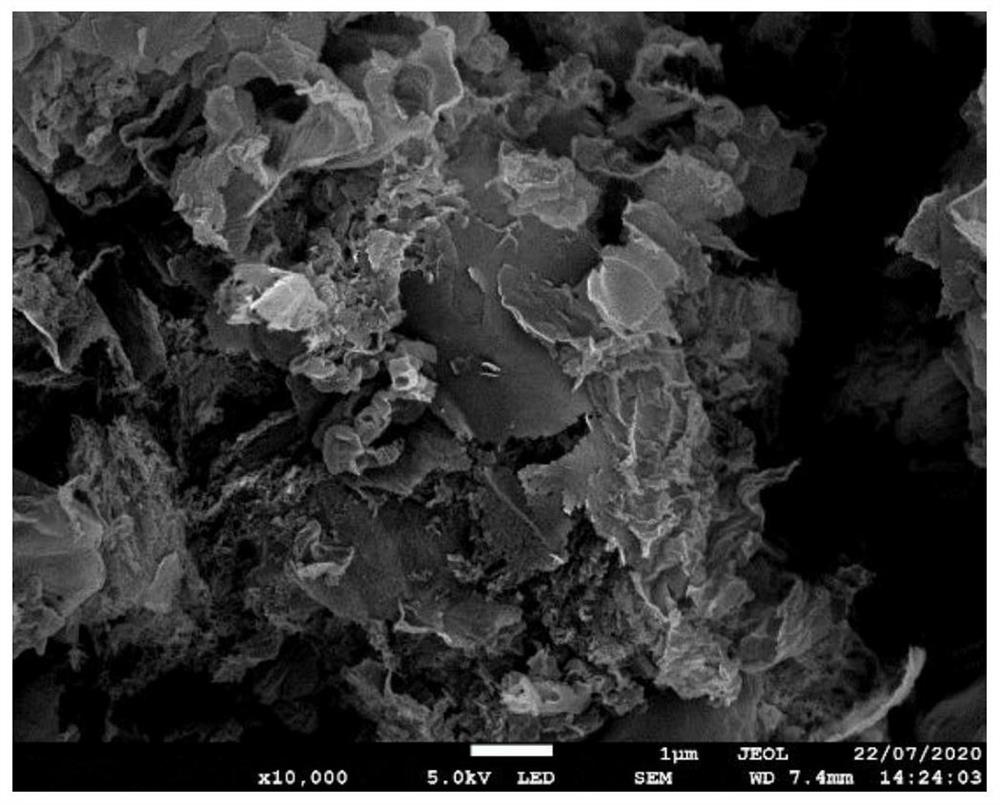

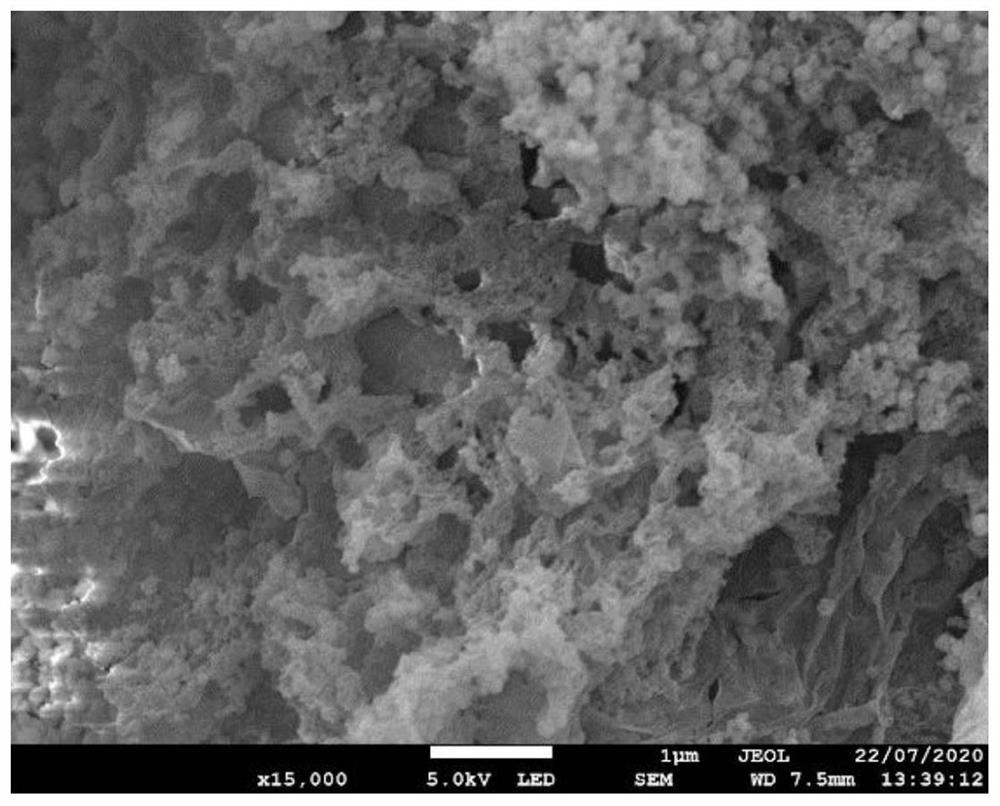

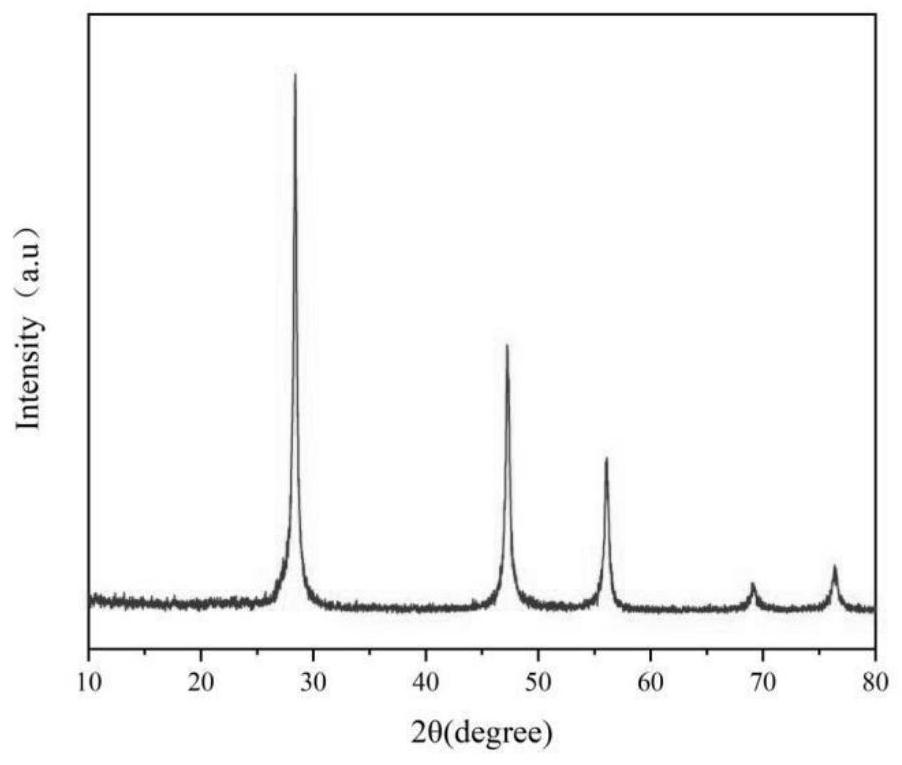

[0077] Use melamine as the precursor, place it in a muffle furnace, raise the temperature to 500°C at a rate of 2°C in an air atmosphere, keep it warm for 2 hours, and obtain a light yellow block-like material after primary sintering after cooling; The material continues to heat up to 550°C at a rate of 2°C under the air atmosphere in the muffle furnace, and is kept for 4 hours. After cooling, a white thin-layered material after secondary sintering is obtained; the material after secondary sintering is 0.1g / The amount of 100mL is evenly dispersed in the reaction solution composed of ammonia water, deionized water, organic dispersion (ethanol) and CTAB (wherein the volume ratio of ammonia water, deionized water and ethanol is 1:50:15, and the amount of CTAB added is 0.2g / 100mL), then slowly add tetraethyl orthosilicate, the addition amount is 5v.t.% (based on the reaction liquid system, the following cases, unless otherwise stated, the addition amount of silicate is based on t...

Embodiment 2

[0081] Use melamine as the precursor, place it in a muffle furnace, raise the temperature to 450°C at a rate of 1°C in an air atmosphere, keep it warm for 3 hours, and obtain a light yellow block-like material after primary sintering after cooling; The material continues to be heated to 500°C at a rate of 1°C under the air atmosphere in the muffle furnace, and is kept for 6 hours. After cooling, a white thin-layered material after secondary sintering is obtained; the material after secondary sintering is 0.05g / The amount of 100mL is evenly dispersed in the reaction solution composed of ammonia water, deionized water, organic dispersion (ethanol) and CTAB, wherein the volume ratio of ammonia water, deionized water and ethanol is 1:70:10, and the amount of CTAB added is 0.3 g / 100mL, then slowly add tetraethyl orthosilicate in an amount of 5v.t.%, react at 50°C for 24 hours, wash the product repeatedly with ethanol and deionized water, and dry at 80°C to obtain a silicon-carbon c...

Embodiment 3

[0084] Use melamine as the precursor, place it in a muffle furnace, raise the temperature to 550°C at a rate of 10°C in an air atmosphere, keep it warm for 1 hour, and obtain a light yellow block-like material after primary sintering after cooling; The material continues to be heated to 600°C at a rate of 10°C in the air atmosphere of the muffle furnace, and is kept for 2 hours. After cooling, a white thin-layered material after secondary sintering is obtained; the material after secondary sintering is 0.5g / The amount of 100mL is evenly dispersed in the reaction solution composed of ammonia water, deionized water, organic dispersion (ethanol) and AOT, wherein the volume ratio of ammonia water, deionized water and ethanol is 1:40:40, and the amount of AOT added is 0.1g / 100mL, then slowly add tetraethyl orthosilicate, the addition amount is 5v.t.%. After reacting at 50°C for 24 hours, the product is washed repeatedly with ethanol and deionized water, and dried at 80°C to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com