Imager module and method for producing an imager module

An imager and support module technology, applied in the directions of instrumentation, image communication, transportation and packaging, can solve the problems of defocusing, damage to image quality, permanent deformation of the receiving part of the lens group, etc., and achieve a low-cost, accurate and reliable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

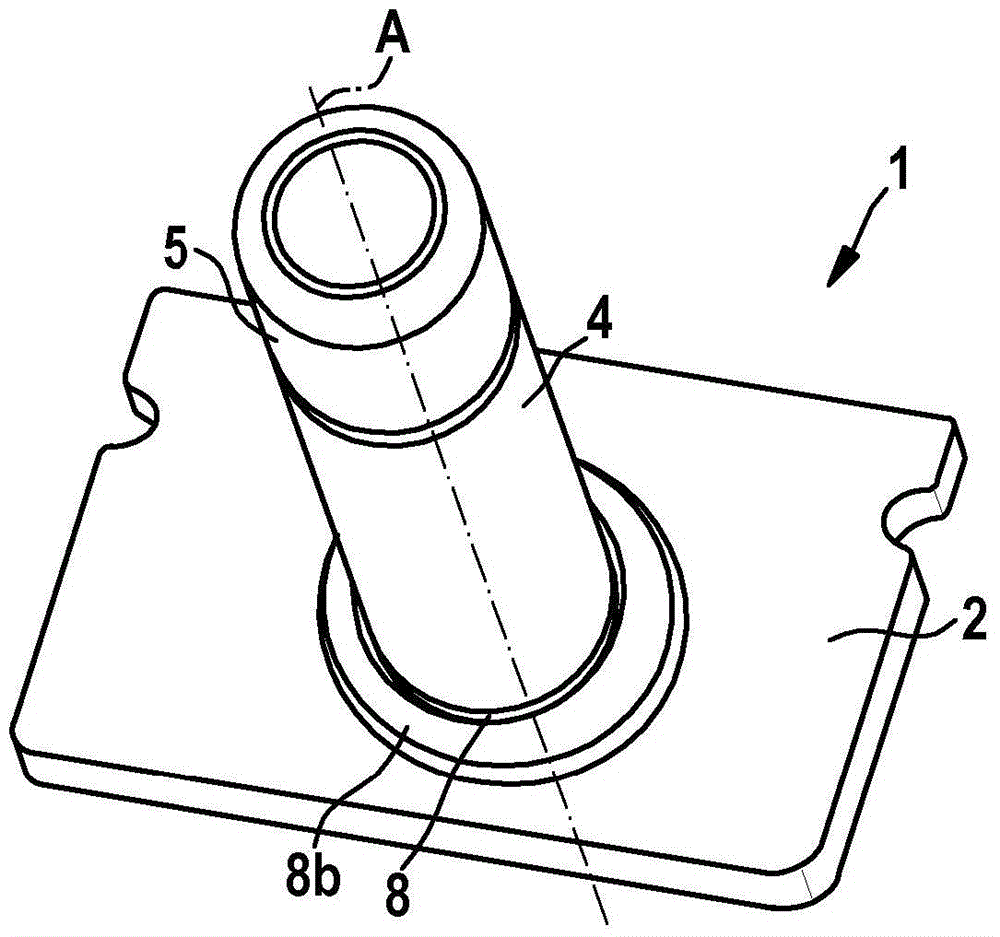

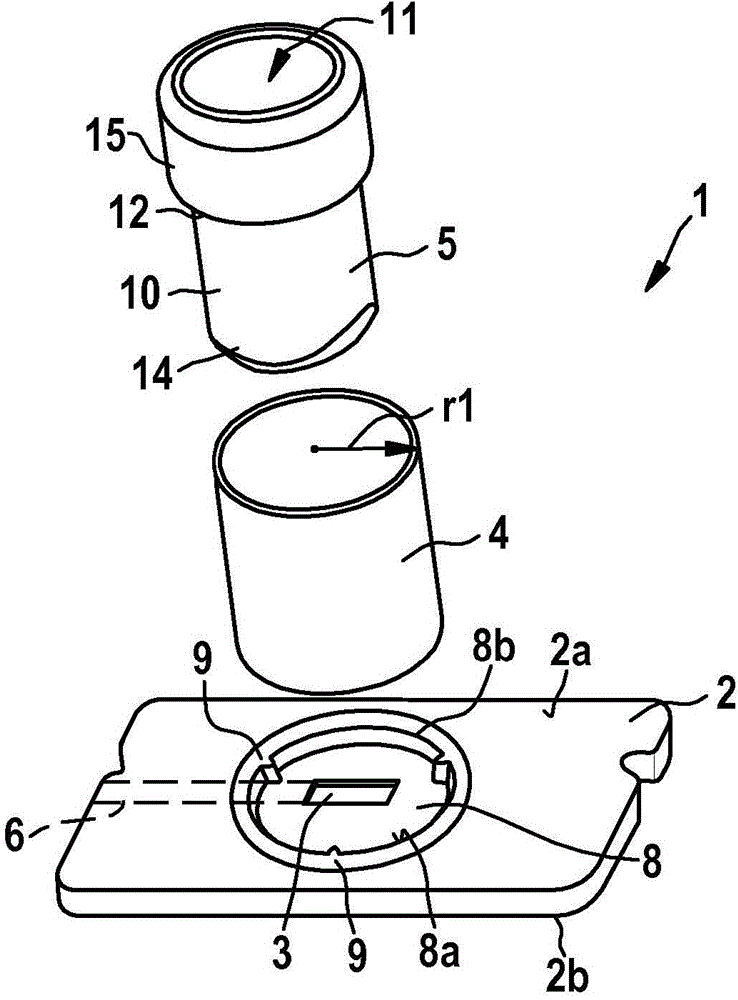

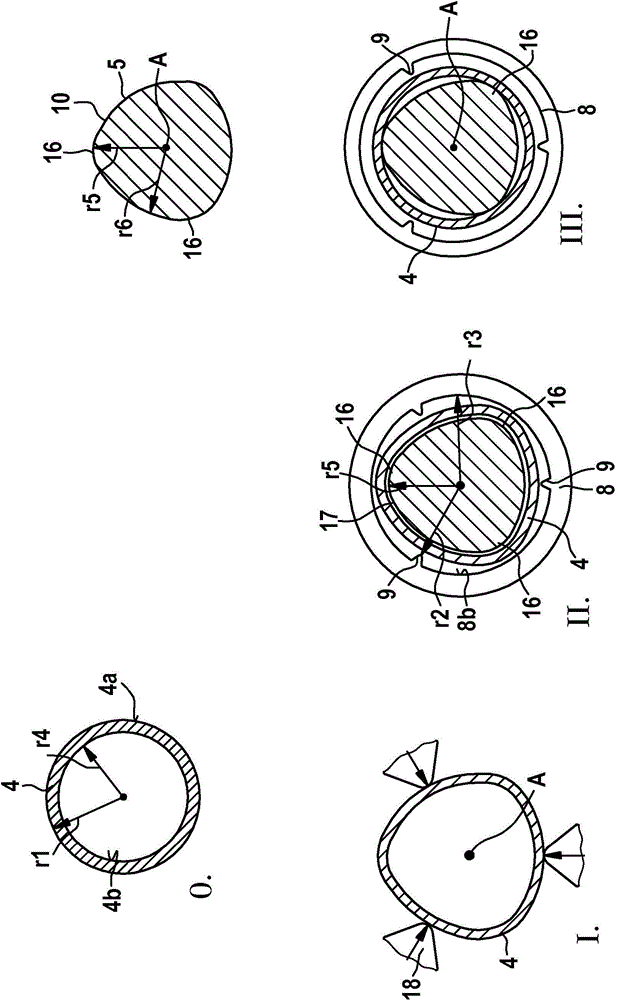

[0031] according to Figures 1 to 5 The imager module 1 has a sensor carrier 2 , an image sensor 3 mounted on the sensor carrier 2 , a substantially tubular clamping sleeve made of elastic material, and an optics 5 .

[0032]The sensor carrier 2 is used for mounting and connecting the image sensor 3 and for receiving the clamping sleeve 4 . The sensor carrier 2 can be, for example, a MID (Molded Interconnect Device) or an injection-moulded circuit carrier and has on its underside 2 b wires or conductor tracks 6 , by means of which the image sensor 3 is connected. A recess 7 is formed in the sensor carrier 2 . In flip-chip technology, image sensor 3 is aligned by means of its sensitive surface to mirror assembly 5 via recess 7 and is connected to conductor track 6 , for example via solder bumps (not shown in further detail). In this case, the sensor may in particular be unencapsulated and be oriented with its sensitive surface through the cutout without further covering; howe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com