Spraying machine

A spraying machine and spray boom technology, which is applied in the field of agricultural vehicles, can solve problems such as small ground clearance, excessive seedling pressure, and harm to human health, and achieve the effects of improving the life of the vehicle, ensuring spray quality, and improving spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

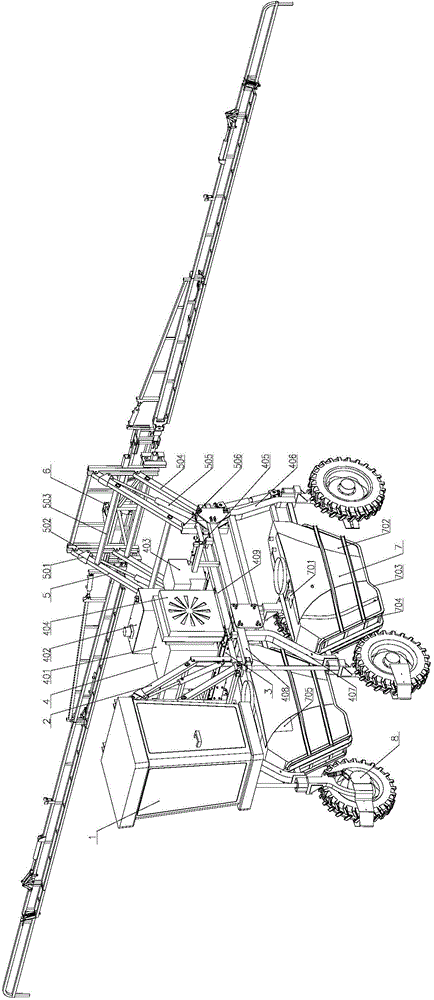

[0051] Such as figure 1 As shown, the sprayer of the present invention includes a cab 1, a cab lifting device 2, a wheel base assembly 3, a chassis power system 4, a spray rack lifting device 5, a spray rod assembly 6, a medicine box assembly 7, a wheel assembly 8. Vehicle hydraulic system.

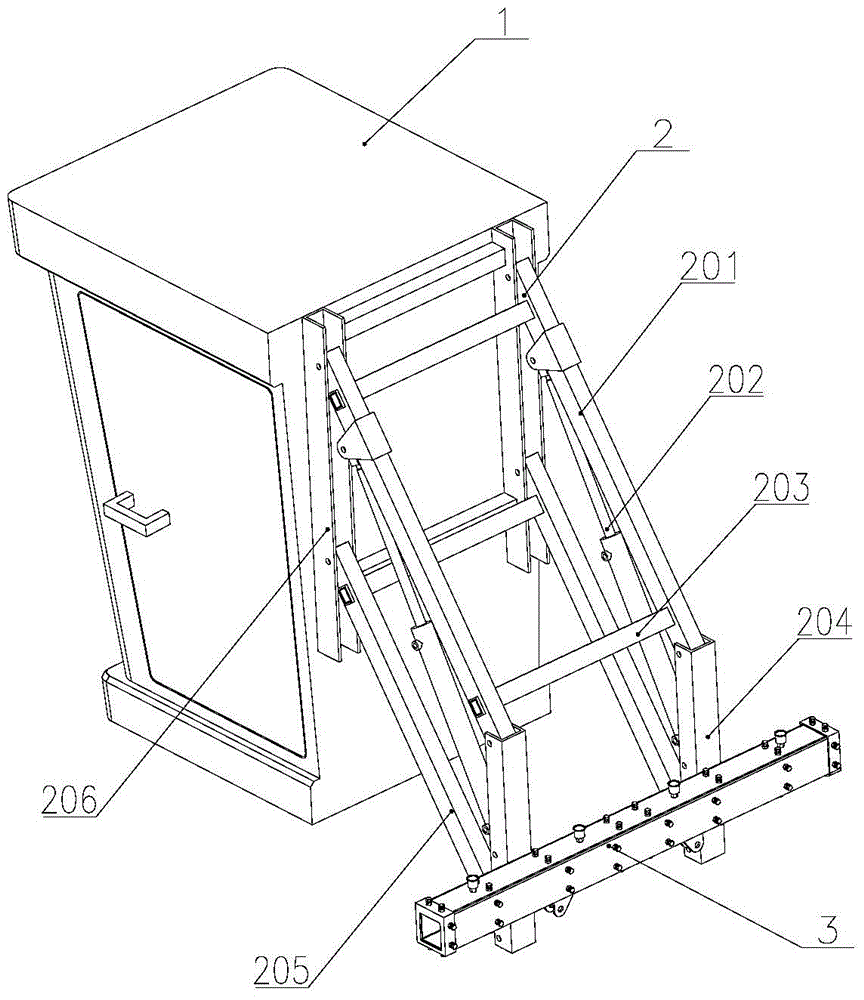

[0052] Such as figure 2 As shown, the cab lifting device includes parallel rods 201 on the cab, cab lifting cylinders 202, cab lateral stabilizer bars 203, cab lifting fixed mounts 204, parallel rods 205 and cab lifting mobile frames 206 under the cab. Wherein the cab lifting mobile frame 206 is welded on the rear portion of the cab 1, and is firmly connected with the cab 1; the cab lifting fixed frame 204 is welded on the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com