A kind of manganese source powder with core-shell structure for powder metallurgy and preparation method thereof

A technology of core-shell structure and powder metallurgy, which is applied in the field of powder metallurgy, can solve the problems of low oxygen content mechanical properties, manganese-containing low alloy steel, reduce the oxidation degree of manganese source powder, and high manganese content, and achieve good oxidation resistance and easy parameters control, nitrogen content controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

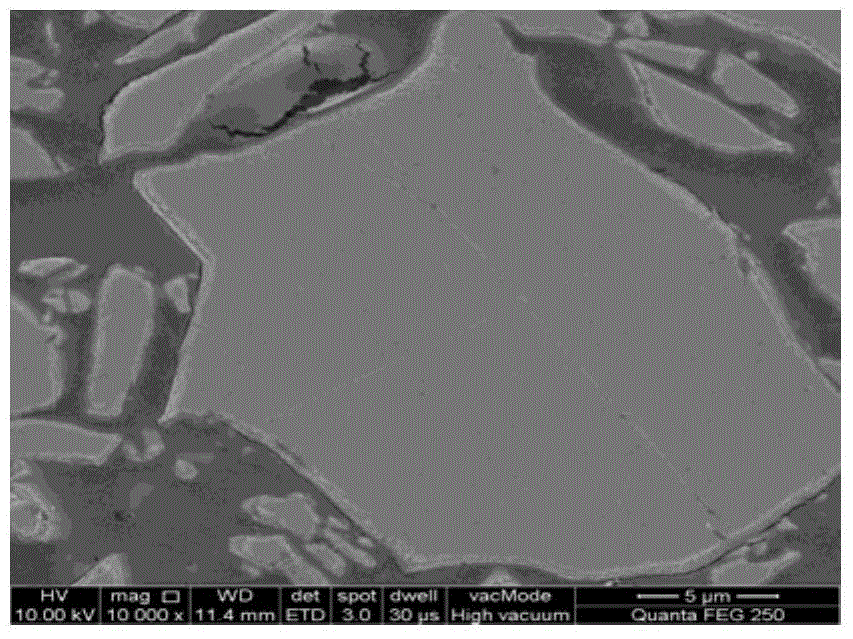

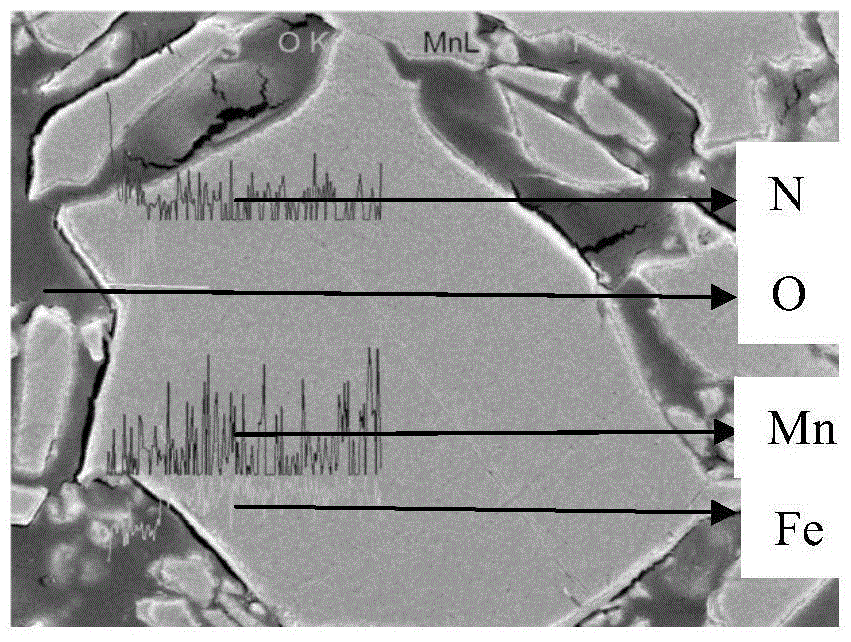

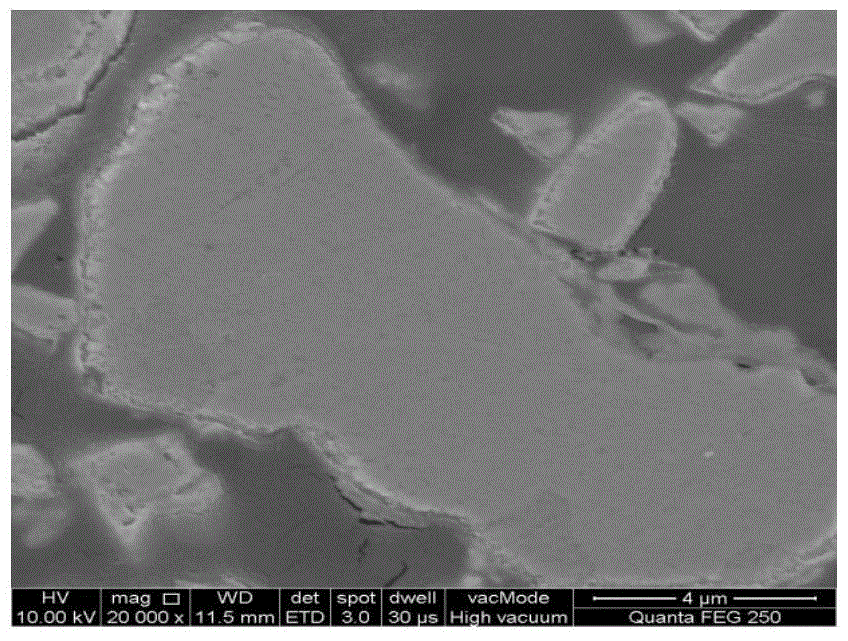

[0045] Pass 100g of electrolytic manganese powder with a content greater than 99% through a 300-mesh sieve, and put it into a 40×20×12mm 3 In the porcelain boat, and then put the porcelain boat into the high temperature electrolytic furnace. The heating rate is 20°C / min, and the porcelain boat is kept at a temperature of 600°C for 60, 90, 120, and 180 minutes, and the atmosphere is 75% H 2 +25%N 2 , the pressure is normal pressure, and the gas flow rate is 3L / min. After the holding time is over, push the porcelain boat to the water circulation cooling area to cool for 15 minutes and then take it out. The measured nitrogen content of the manganese nitride powder is shown in Table 1.

[0046] Table 1 Effect of treatment process on nitrogen content of manganese-containing powder

[0047]

Embodiment 2

[0049] Ball mill FeMn (manganese content is 76%) alloy powder for 1h, the median diameter of the powder after ball milling is 21.72μm, weigh 100g of FeMn alloy powder after ball milling, and pack it into 40×20×12mm 3 In the porcelain boat, and then put the porcelain boat into the high temperature electrolytic furnace. The heating rate is 20°C / min, the porcelain boat is kept at 600°C for 60 and 180min, and the atmosphere is 75% H 2 +25%N 2 , the pressure is normal pressure, and the gas flow rate is 3L / min. After the holding time is over, push the porcelain boat to the water circulation cooling area to cool for 15 minutes and then take it out. The measured nitrogen content of the iron-manganese nitride powder is shown in Table 2.

[0050] Table 2 Effect of nitriding treatment on nitrogen content of manganese-containing powder

[0051]

Embodiment 3

[0053] Pass 100g of electrolytic manganese powder with a content greater than 99% through a 300-mesh sieve, and put it into a 40×20×12mm 3 In the porcelain boat, and then put the porcelain boat into the high temperature electrolysis furnace. The heating rate is 5°C / min, the porcelain boat is kept at a temperature of 600°C for 12 hours, and the atmosphere is 75%H 2 +25%N 2 , the pressure is normal pressure, the gas flow rate is 3L / min, after the holding time is over, it is cooled with the furnace, and the circulation of nitrogen-containing atmosphere is maintained during the cooling process. The nitrogen content and oxygen content of the manganese nitride powder were measured to be 3.50% and 0.702%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com