Dual-drive jogging holder

A dynamic clamping and dual-drive technology, applied in the field of manufacturing, can solve problems such as complex structures, achieve the effects of simplifying the mechanical structure, minimizing the motion transmission chain, and improving motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

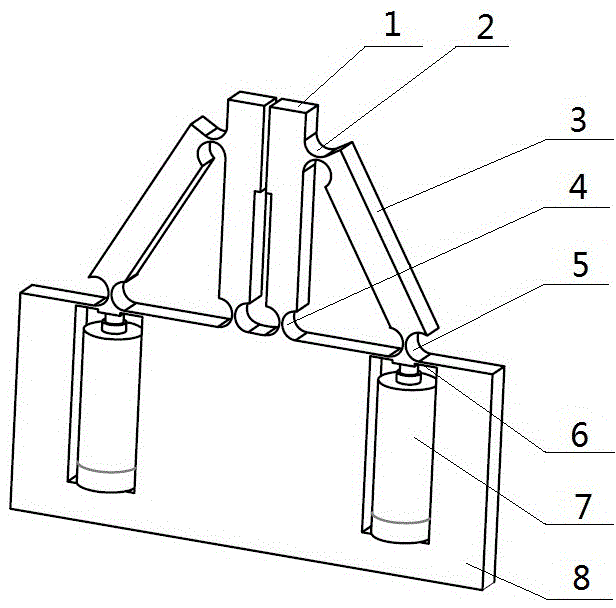

[0010] The clamping fingers 1 are two whose lower ends are connected to the fixed platform 8 through the elastic rotating pair 4 and installed face to face. The two branch chains are symmetrically distributed on both sides of the symmetrical plane of the two clamping fingers 1. It includes a connecting rod 3, an elastic thin plate 6 and a micro-displacement driving device 7, wherein one end of the connecting rod 3 is connected to the upper end of the clamping finger 1 through the elastic rotating pair 2, and the other end is connected to the elastic thin plate 6 through the elastic rotating pair 5. The middle part of one side is fixedly connected, the middle part of the other side of the elastic thin plate 6 is fixedly connected with one end of the micro-displacement driving device 7, the other end of the micro-displacement driving device 7 is fixedly connected with the fixed platform 8, and both ends of the elastic thin plate 6 are connected with the fixed platform. 8 fixed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com