An Injection Molding Production Process for Reducing Warping of Plastic Flat Plates

A production process and plastic technology, which is applied in the field of production requirements of plastic shading plates for photographic lamps, can solve the problems of prolonged molding time, expansion of cooling water pipe diameter, and increase in injection cost, so as to reduce warpage deformation, shorten production time, The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

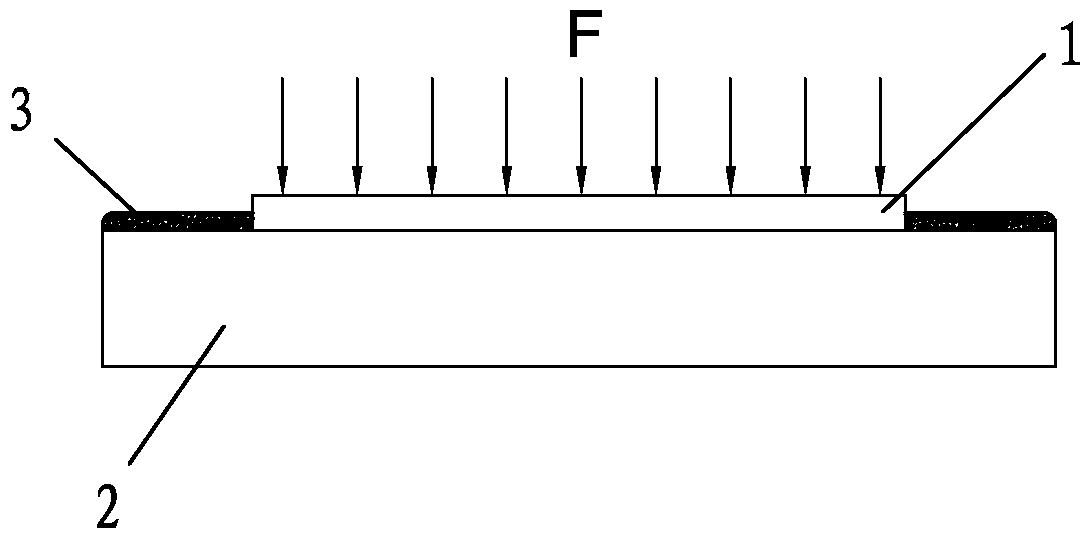

[0034] Example 1: Please refer to figure 1 Shown step 1, setting a smooth platform 2, to described smooth platform 2

[0035] Add liquid 3 to the surface to evenly distribute liquid 3 on the surface of the smooth platform;

[0036] Step 2, making the plastic flat plate 1 into shape through injection molding process;

[0037] Step 3, placing the plastic plate 1 after demoulding on the smooth platform 2;

[0038] Step 4, apply force to make the plastic plate 1 rub against the surface of the smooth platform 2 where the liquid is distributed and pass the liquid 3

[0039] Make the plastic plate 1 and the smooth platform 2 vacuum-adsorb, and remove the applied force;

[0040] Step 5, further cooling and shaping the vacuum-adsorbed plastic plate 1 and the smooth platform 2 .

[0041] Step 6. Remove the cooled and shaped plastic plate 1 from the smooth platform 2, and pick up the plastic plate 1.

Embodiment 2

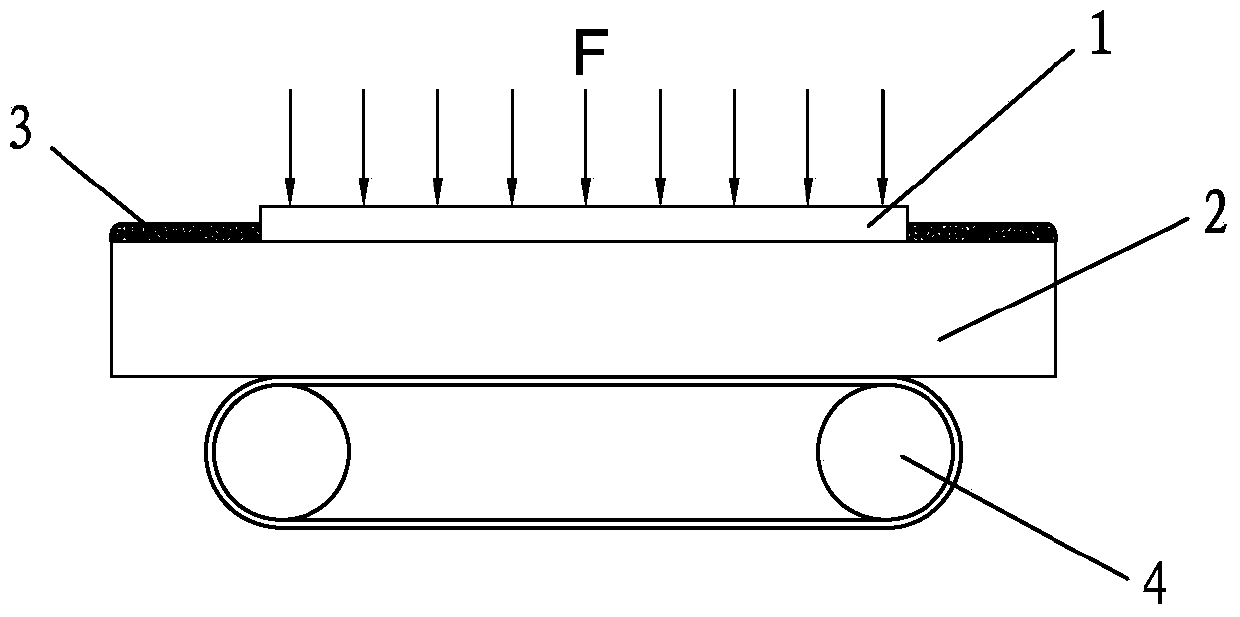

[0042] Example 2: Please refer to figure 2 Shown step 1, setting a smooth platform 2, to described smooth platform 2

[0043] Add liquid 3 to the surface to evenly distribute liquid 3 on the surface of the smooth platform;

[0044] Step 2, making the plastic flat plate 1 into shape through injection molding process;

[0045] Step 3, placing the plastic plate 1 after demoulding on the smooth platform 2;

[0046] Step 4, apply force to make the plastic plate 1 pass the vibrator 4 on the surface of the smooth platform 2 where the liquid is distributed, and vibrate

[0047] The smooth platform is moved, and the plastic plate and the smooth platform are vacuum-adsorbed by the liquid, and the force is removed;

[0048] Step 5, further cooling and shaping the vacuum-adsorbed plastic plate 1 and the smooth platform 2 .

[0049] Step 6. Remove the cooled and shaped plastic plate 1 from the smooth platform 2, and pick up the plastic plate 1.

Embodiment 3

[0050] Example 3: Please refer to figure 1 Shown step 1, setting a smooth platform 2, to described smooth platform 2

[0051] Add liquid 3 to the surface to evenly distribute liquid 3 on the surface of the smooth platform;

[0052] Step 2, making the plastic visor 1 of the photography light through injection molding process;

[0053] Step 3, placing the plastic shade 1 of the photographic light after demoulding on the smooth platform 2;

[0054] Step 4, apply force to make the plastic shading plate 1 of the photography light pass through the friction on the surface of the smooth platform 2 where the liquid is distributed.

[0055] Through the liquid 3, the plastic visor 1 of the photography light and the smooth platform 2 are vacuum-adsorbed, and the applied force is removed;

[0056] Step 5. Further cooling the plastic shading plate 1 and the smooth platform 2 of the vacuum-adsorbed photography lamp

[0057] Shaping, cooling and shaping the best time is 20min. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com