A kind of dual-source trolleybus electricity control method

A trolleybus and electric control technology, applied in electric vehicles, electric traction, power lines, etc., can solve the problems of voltage jump, damage to the power collection system and line network, etc., to prevent voltage jump, line network internal resistance loss The effect of reducing and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

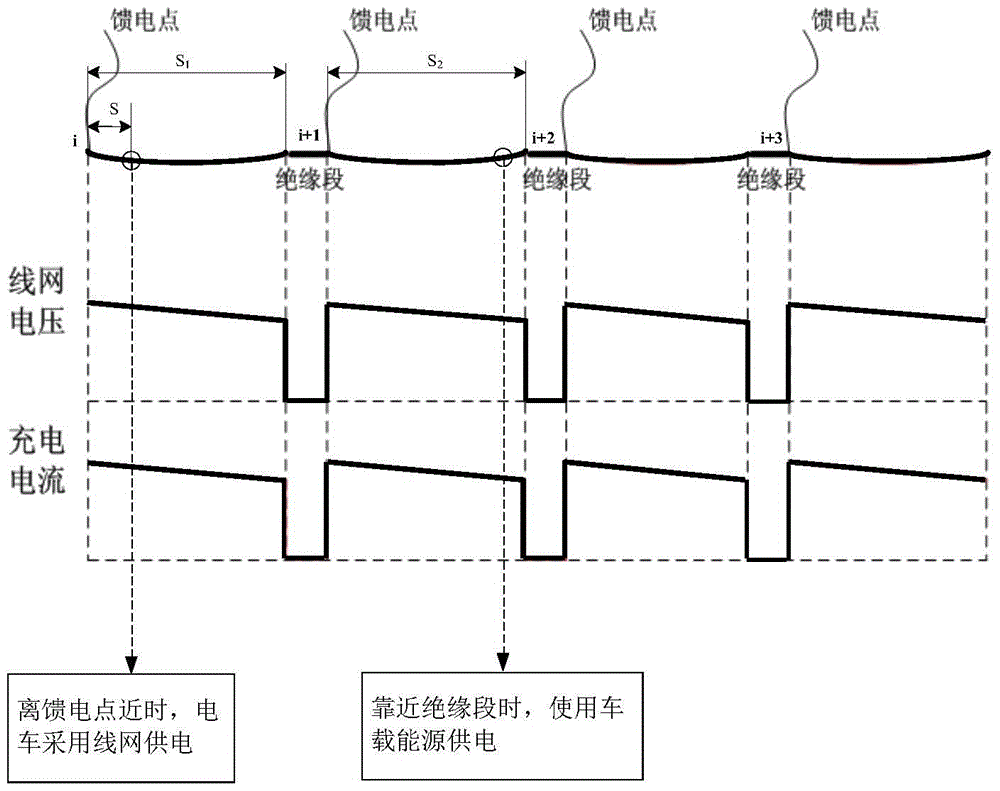

[0020] The invention provides a dual-source trolleybus electricity control method. The control principle of the method is as follows: the power supply line network of the trolleybus is divided into several operating sections, and each operating section consists of a power supply section capable of supplying power and an adjacent section The power supply section is composed of an insulating section that cannot supply power. The feed point of the power supply section is connected to the power grid through a wire. When the feed point or in the insulation section, the line network power supply is stopped, and the tram is powered by the on-board energy to achieve the purpose of actively eliminating voltage jumps.

[0021] Such as figure 1 As shown, the insulation segment i and its adjacent length are S 1 The power supply section constitutes the i-th operating interval, and the insulation section i+1 and its adjacent length are S 2 The power supply section constitutes the i+1th op...

Embodiment 2

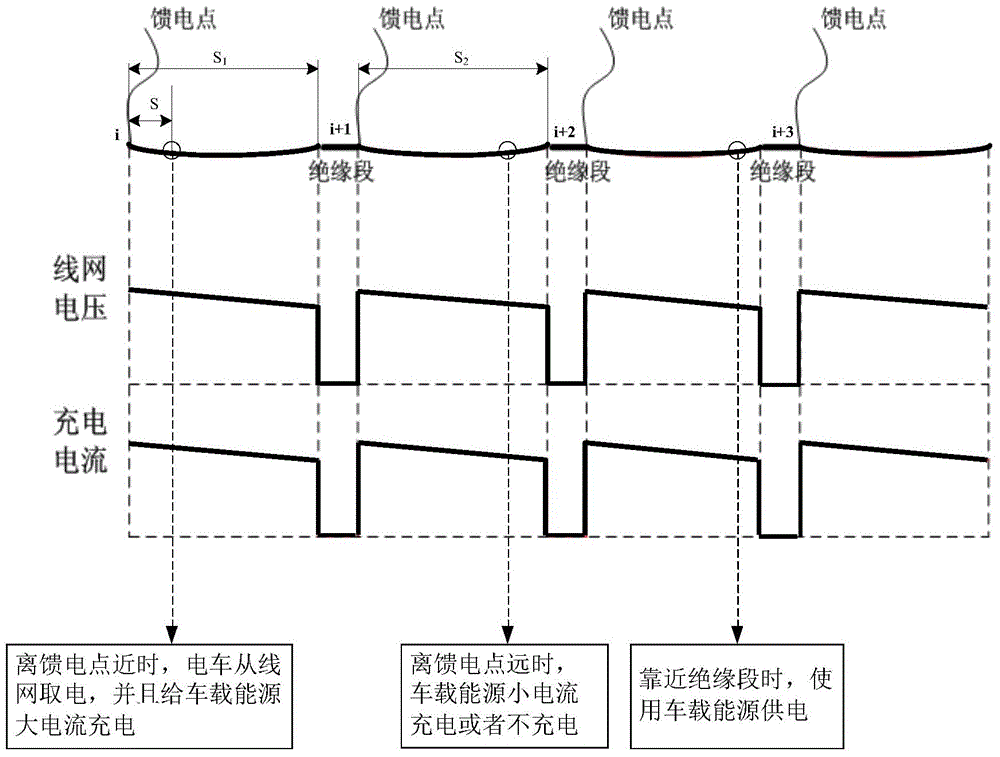

[0024] The difference between this embodiment and Embodiment 1 is that in addition to using different power sources for power supply at different positions in the operating interval, within the set distance close to the feed point, the charging current of the line network to the electric vehicle on-board energy is the same as that in the corresponding operating interval. The distance of the tram from the feed point is related: the greater the distance of the tram from the feed point, the lower the supply current.

[0025] Such as figure 2 As shown, when the tram is close to the feed point, the tram takes power from the line network in the power supply section of the running section, and at the same time, the line network charges the vehicle energy with a large current; when the distance between the tram and the feed point gradually increases, the charging The current gradually decreases; when the distance between the electric car and its nearest insulating section is reduced ...

Embodiment 3

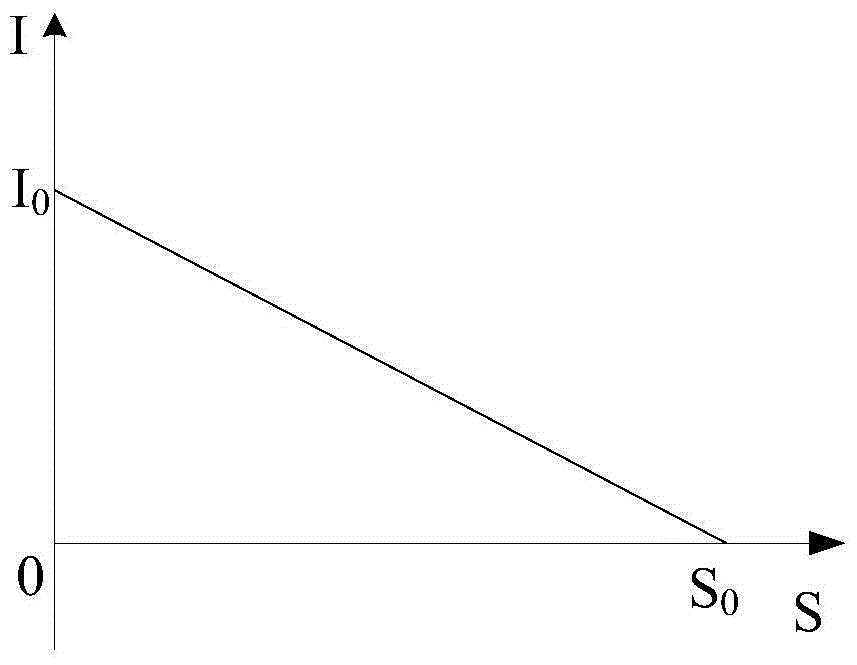

[0027] Such as image 3 As shown, in each operating interval, the charging current value of the on-board power supply decreases linearly with the increase of the distance between the tram and the feeding point of the operating interval, wherein the charging current value at the feeding point I is the maximum I 0 , with the increase of the distance S between the current collector and the feeding point of the operating range, the charging current value I decreases continuously, when S reaches the set distance S 0 When the charging current is the smallest, it can even be directly reduced to 0. According to the distance S between two insulation segments 供 And the calculated S, set up the current coefficient k (0≤k≤1) to control the charging current, that is, k=f(s,s 供 ), the charging current is adjusted according to the constant change of S, and the vehicle controller sends a control signal of the charging current to the collector controller.

[0028] Since the power supply se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com