Eucalyptus yarding equipment

A technology of skidding and equipment, applied in the field of skidding equipment for eucalyptus, can solve the problems of small application range and high cost, and achieve the effects of wide application range, energy saving, and increased freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing:

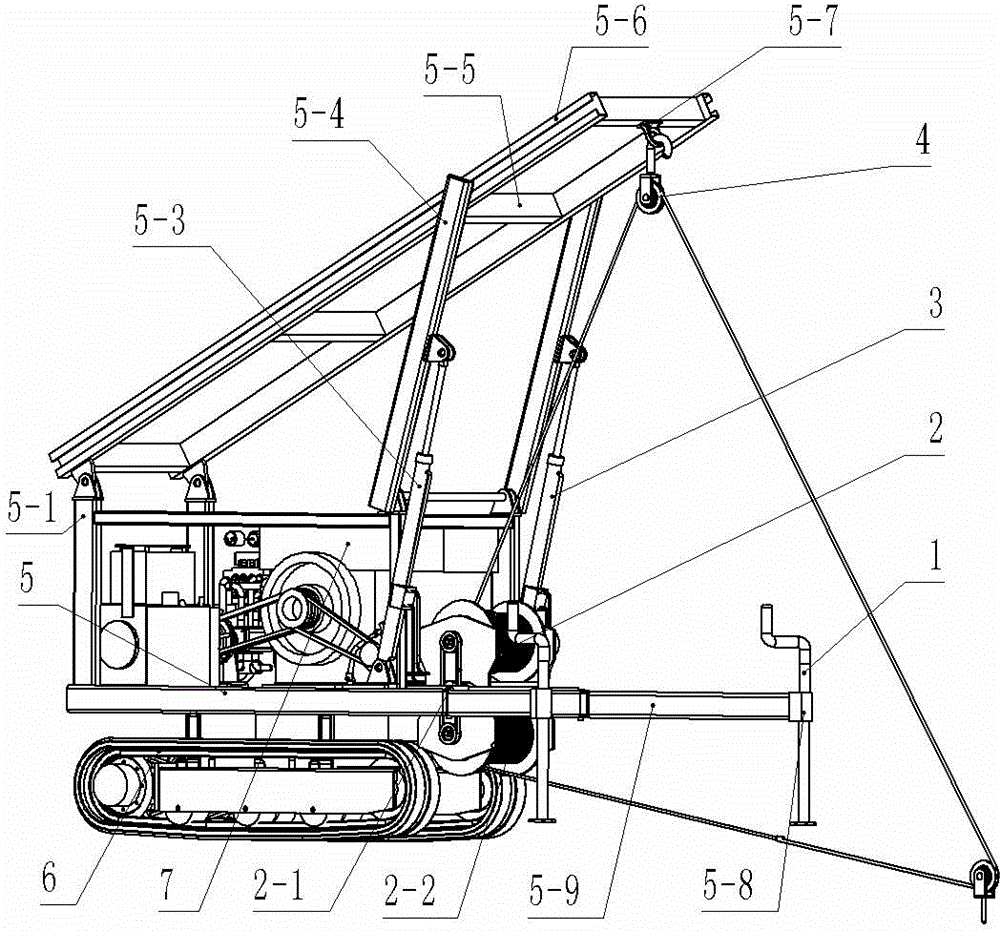

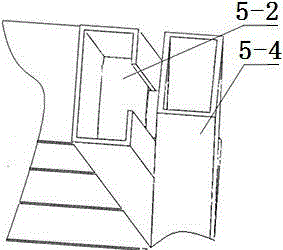

[0012] Such as figure 1 The eucalyptus skidding equipment shown includes a vehicle frame 5 with a traveling device 6 and a hydraulic winch mounted on the front of the vehicle frame 5. The hydraulic winch includes two hoists 2 arranged up and down, and the two hoists 2 are installed in front of the vehicle frame 5. On the support of the part, two winches 2 driven by the power machine are connected by belt 2-1 transmission, and the power machine of the present embodiment is a diesel engine 7; wherein a winch 2 installed on the top of the vehicle frame 5 support is wound with a steel wire rope, Another winch 2-2 that is contained in vehicle frame 5 support bottoms is wound with the rope that is connected with described wire rope, and present embodiment is equipped with a movable pulley 4 with hook and a movable pulley with nail on wire rope and rope; Mounting frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com