Core board for fireproof door

A fire door core and board technology, applied in the field of fireproof materials, can solve the problems of moisture absorption, brine return, waste, serious corrosion of the fire door steel substrate, etc., and achieve the effect of improving the flexural and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

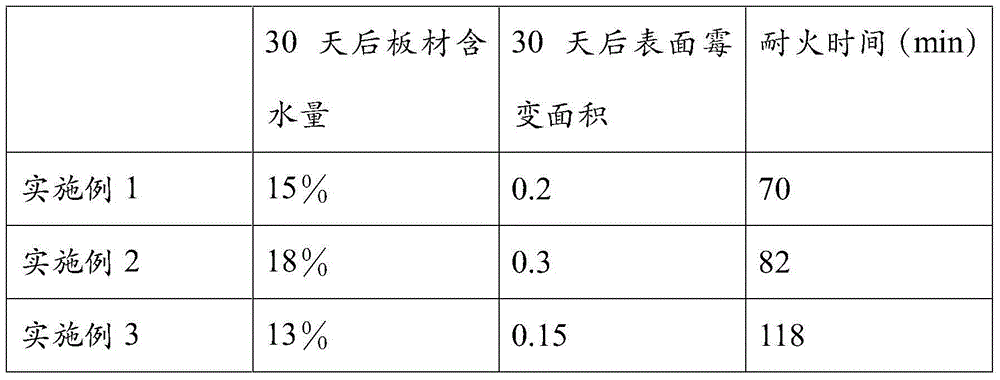

Examples

Embodiment 1

[0078] A fire door core plate, composed of the following components in mass percentage:

[0079] Solid material 60%, liquid material 40%;

[0080] Taking the total amount of solid material as 100%, among them,

[0081] MgSO 4 ·7H 2 O, 30%;

[0082] MgO, 60%;

[0083] Silica powder, 11%;

[0084] Admixture, 3%;

[0085] Taking the total amount of liquid material as 100%, among them,

[0086] Magnesium sulfate aqueous solution, 50%;

[0087] Foaming agent, 3%;

[0088] water, 40%,

[0089] Its preparation method is: take the total material 1000g as an example

[0090] Step 1. Weigh the required MgSO in proportion 4 Add a certain amount of tap water to 7H2O in a large beaker, and stir to dissolve in a constant temperature water bath at 50°C;

[0091] Step 2. Weigh the required MgO and silicon micropowder in proportion, and fully mix them in a barrel for later use;

[0092] Step 3. After the magnesium sulfate in step 1 is completely dissolved, take it out, add a proport...

Embodiment 2

[0097] A fire door core plate, composed of the following components in mass percentage:

[0098] 70% solid material, 30% liquid material;

[0099] Taking the total amount of solid material as 100%, among them,

[0100] MgSO 4 ·7H 2 O, 35%;

[0101] MgO, 50%;

[0102] Silica powder, 13%;

[0103] Admixture, 2%;

[0104] Taking the total amount of liquid material as 100%, among them,

[0105] Magnesium sulfate aqueous solution, 60%;

[0106] Foaming agent, 2%;

[0107] water, 45%,

[0108] The preparation method is the same as in Example 1.

Embodiment 3

[0110] A fire door core plate, composed of the following components in mass percentage:

[0111] Solid material 66.47%, liquid material 33.53%;

[0112] Taking the total amount of solid material as 100%, among them,

[0113] MgSO 4 ·7H 2 O, 30.91%;

[0114] MgO, 54.91%;

[0115] Silica powder, 12.12%;

[0116] Admixture, 2.06%;

[0117] Taking the total amount of liquid material as 100%, among them,

[0118] Magnesium sulfate aqueous solution, 54.75%;

[0119] Foaming agent, 2.52%;

[0120] Water, 42.73%.

[0121] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com