Production process of environment-friendly colored non-woven fabric

A production process and non-woven technology, applied in the production process field of environmentally friendly colored non-woven fabrics, can solve the problems of unfavorable color non-woven fabric aesthetics, lack of anti-wrinkle and anti-folding processing technology, non-woven fabrics prone to creases and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

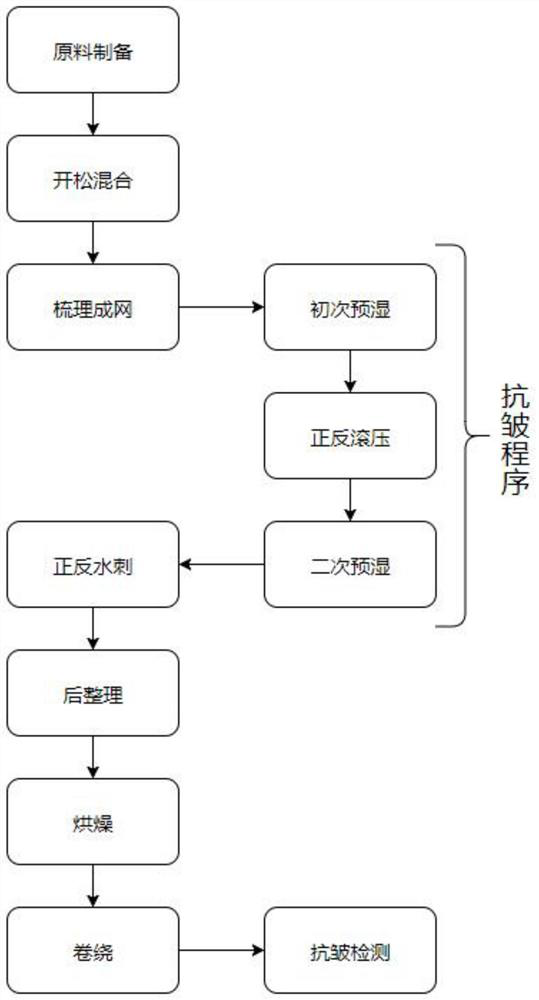

[0030] see figure 1 , the present invention provides a technical solution: a production process of environmentally friendly colored non-woven fabrics, comprising the following steps:

[0031] Step 1, raw material preparation, prepared according to weight: 20 parts of polypropylene, 2 parts of bamboo fiber, 1 part of flax, 2 parts of coconut shell fiber, 1 part of kapok fiber, 5 parts of sisal hemp, 3 parts of sawdust, 1.5 parts of silk;

[0032] Step 2, opening and mixing, the polypropylene is divided into two equal parts, and the two equal parts polypropylene and the remaining raw materials in step 1 are mixed and opened respectively;

[0033] Step 3. Combing into a net, combing all raw materials except polypropylene into a base layer, and then carding two equal parts of polypropylene into a covering layer, and using an adhesive to adhere the two covering layers to the upper and lower surfaces of the base layer respectively , to form a fiber net; the covering layer is the ex...

Embodiment 2

[0049] see figure 1 , the present invention also provides a technical solution: a production process of environmentally friendly colored non-woven fabrics, comprising the following steps:

[0050] Step 1, raw material preparation, prepared according to weight: 25 parts of polypropylene, 3 parts of bamboo fiber, 3 parts of flax, 5 parts of coconut shell fiber, 2 parts of kapok fiber, 7 parts of sisal hemp, 4 parts of wood chips, and 3 parts of silk;

[0051] Step 2, opening and mixing, the polypropylene is divided into two equal parts, and the two equal parts polypropylene and the remaining raw materials in step 1 are mixed and opened respectively;

[0052] Step 3. Combing into a net, combing all raw materials except polypropylene into a base layer, and then carding two equal parts of polypropylene into a covering layer, and using an adhesive to adhere the two covering layers to the upper and lower surfaces of the base layer respectively , to form a fiber net; the covering lay...

Embodiment 3

[0068] see figure 1 , the present invention also provides a technical solution: a production process of environmentally friendly colored non-woven fabrics, comprising the following steps:

[0069] Step 1, raw material preparation, prepared according to weight: 22 parts of polypropylene, 2.5 parts of bamboo fiber, 1.5 parts of flax, 3 parts of coconut shell fiber, 1.6 parts of kapok fiber, 6.3 parts of sisal, 3.5 parts of wood chips, 2.2 parts of silk;

[0070] Step 2, opening and mixing, the polypropylene is divided into two equal parts, and the two equal parts polypropylene and the remaining raw materials in step 1 are mixed and opened respectively;

[0071] Step 3. Combing into a net, combing all raw materials except polypropylene into a base layer, and then carding two equal parts of polypropylene into a covering layer, and using an adhesive to adhere the two covering layers to the upper and lower surfaces of the base layer respectively , to form a fiber net; the covering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com