Rolling technique capable of lowering depeth of steel rail decarburized layer

A decarburization layer and depth technology, applied in the field of rail rolling production, can solve the problems of traffic safety impact, cumbersome heating control process control, reduce the decarburization layer of the rail head, etc., and achieve the effect of simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

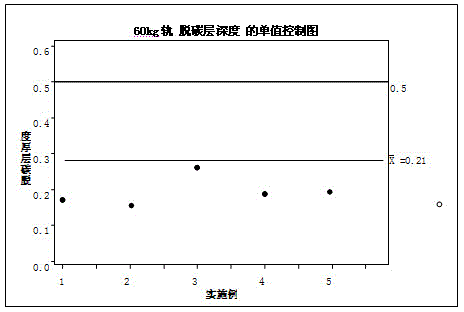

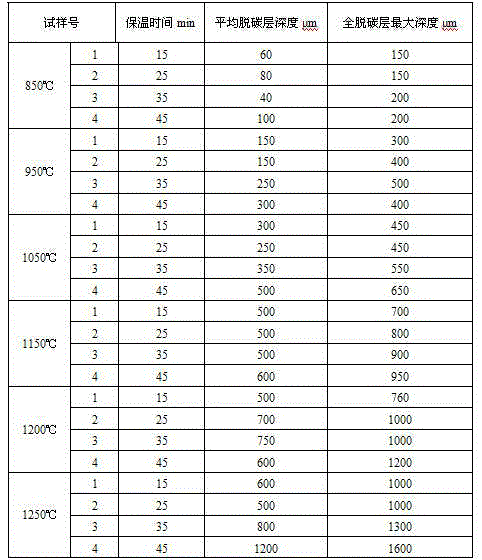

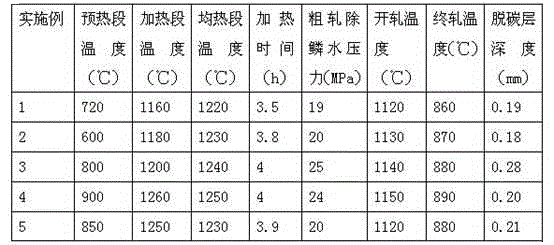

[0017] The present invention is a rolling process capable of reducing the depth of decarburization layer of rails, which includes continuous casting slab heating, high-pressure water descaling, BD1 rolling mill billet opening, BD2 rolling mill billet opening, rough rolling high-pressure water descaling, universal rolling mill rolling and UF In the finishing rolling step, the continuous casting slab is heated using a walking heating furnace, wherein the temperature of the preheating section is <900°C, preferably 600°C to 750°C; the temperature of the heating section is between 1160°C and 1260°C, preferably 1180°C to 1260°C; The temperature of the hot section is 1220°C~1250°C, preferably 1220°C~1240°C; the heating temperature difference of the continuous casting slab does not exceed 30°C, and the heating time is 3.5~4.0h; the pressure of the rough rolling descaling water is ≥19MPa, and the rolling start temperature is 1120~1150 ℃, and the final rolling temperature is controlled a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com