A hydraulic concrete internal anchor method for hanging cables with two-way perforated steel plates

A hydraulic concrete and concrete technology, which is applied in textile cables, construction, textiles and papermaking, etc., to achieve the effect of simple and easy technology, safe and durable operation, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

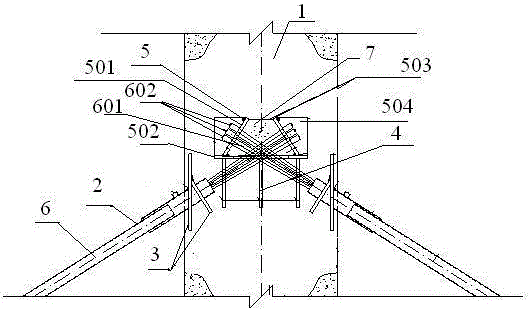

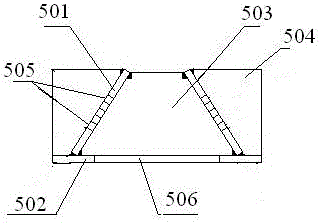

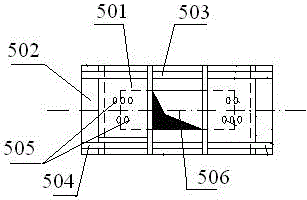

[0051] In the tower frame 4, the internal anchoring force structure of the fixed connection is a two-way perforated steel plate hook structure 5, and each prepared drag cable 6 is passed through the fixed steel plate, and the extrusion head 602 is hung on the fixed steel plate 501, by The extrusion head transmits the cable force to the tower concrete 1 through the two-way perforated steel plate;

[0052] (1) The manufacturing method of the cable:

[0053] The cable is composed of multiple low-relaxation steel strands 601 anchoring end cables, and the production method of one of the low-relaxation steel strand anchoring end cables is as follows:

[0054] If it is a new low-slack steel strand, there is an oil layer, use acetone to clean the extruded area; if there is floating rust on the steel strand, it should be derusted and phosphated first, and brushed with liquid steel surface derusting and phosphating agent Or wash the steel strand, which can directly remove rust and phos...

Embodiment 2

[0084] In the tower frame 4, the internal anchoring force structure of the fixed connection is a two-way perforated steel plate hook structure 5, and each prepared drag cable 6 is passed through the fixed steel plate, and the extrusion head 602 is hung on the fixed steel plate 501, by The extrusion head transmits the cable force to the tower concrete 1 through the two-way perforated steel plate;

[0085] (1) The manufacturing method of the cable:

[0086] The cable is composed of multiple low-relaxation steel strands 601 anchoring end cables, and the production method of one of the low-relaxation steel strand anchoring end cables is as follows:

[0087] If it is a new low-slack steel strand, there is an oil layer, use acetone to clean the extruded area; if there is floating rust on the steel strand, it should be derusted and phosphated first, and brushed with liquid steel surface derusting and phosphating agent Or wash the steel strand, which can directly remove rust and phos...

Embodiment 3

[0122] In the tower frame 4, the internal anchoring force structure of the fixed connection is a two-way perforated steel plate hook structure 5, and each prepared drag cable 6 is passed through the fixed steel plate, and the extrusion head 602 is hung on the fixed steel plate 501, by The extrusion head transmits the cable force to the tower concrete 1 through the two-way perforated steel plate;

[0123] (1) The manufacturing method of the cable:

[0124] The cable is composed of multiple low-relaxation steel strands 601 anchoring end cables, and the production method of one of the low-relaxation steel strand anchoring end cables is as follows:

[0125] If it is a new low-slack steel strand, there is an oil layer, use acetone to clean the extrusion area; if there is floating rust on the steel strand, it should be derusted and phosphated first, and brush with liquid steel surface derusting and phosphating agent Or wash the steel strand, which can directly remove rust and phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com