A rail-type iron driller's turnbuckle pliers

An iron driller and twist pliers technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problem that the synchronization of the movement of the slider at both ends cannot be fully guaranteed, the movement trajectory of the slider cannot be completely straight, and it is not easy to install and Maintenance and other issues to achieve the effect of improving the neutrality, ensuring the neutrality, and facilitating installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

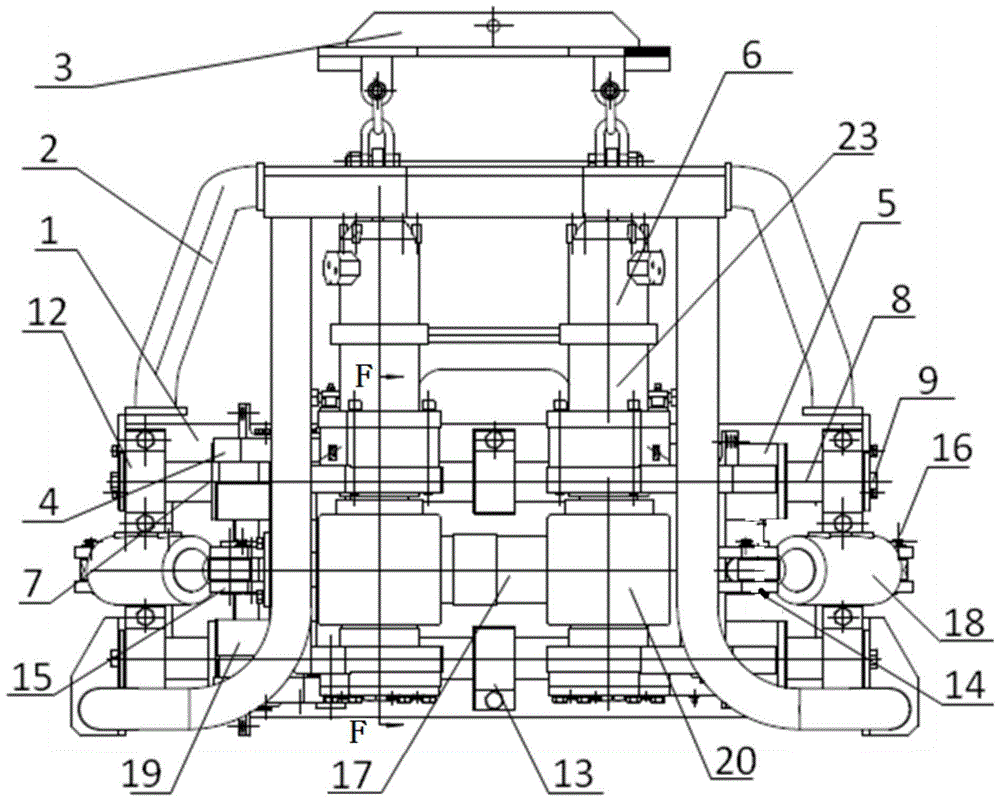

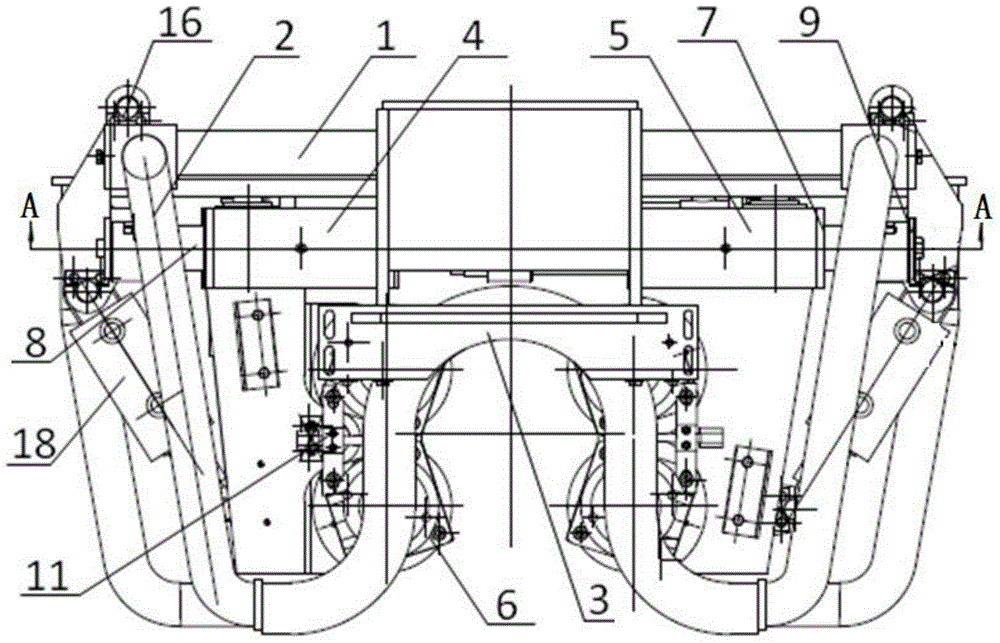

[0024] refer to figure 1 , figure 2 , image 3 , the structure of the present invention is to include a mounting bracket 1, the cross-sectional structure of the mounting bracket 1 is similar to an "F" shape, and a shackle frame 3 is connected to the mounting bracket 1;

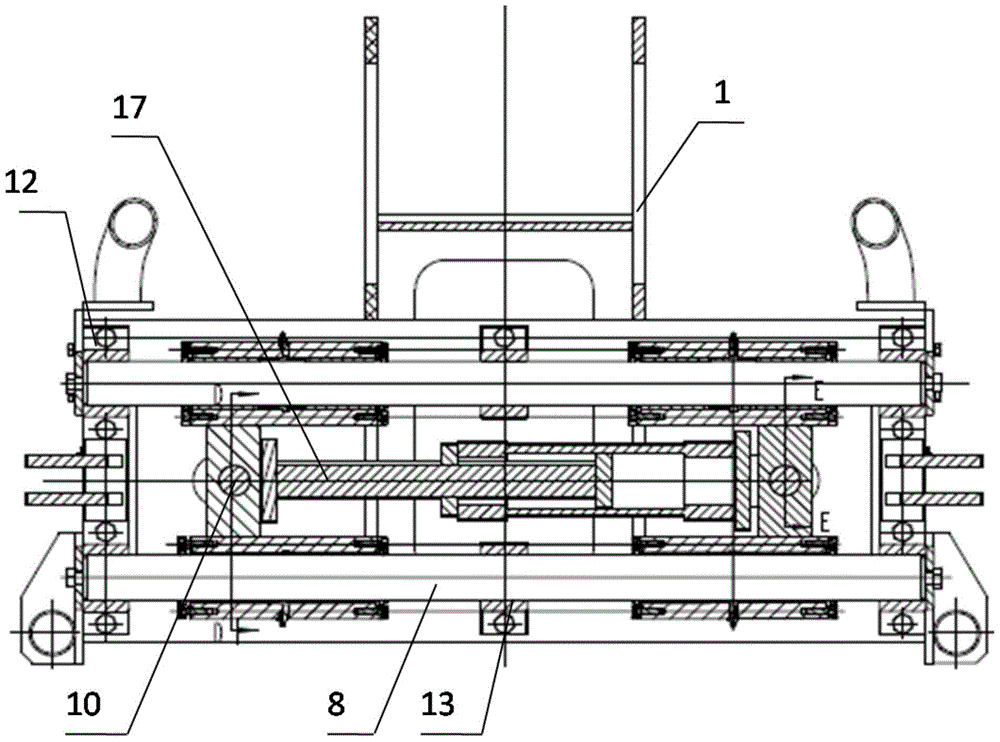

[0025] Mounting bracket 1 rear end both sides up and down respectively are respectively installed with a fixed seat-12 by bolt, between the fixed seats-12 on both sides correspondingly wear guide rod 8, each guide rod 8 two ends stretch out the fixed seat-12 The ends are respectively provided with a sealing plate 9, and the sealing plate 9 and the guide rod 8 are fixedly connected by bolts; the middle position of each guide rod 8 is sleeved with a fixing seat 2 13, and each fixing seat 2 13 is connected to the mounting bracket by bolts. 1 fixedly connected to strengthen t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com