Round cutter box capable of having disc cutter replaced bidirectionally

A technology of disc-shaped hobs and circular knives, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of reducing the overall strength of the cutterhead, affecting the overall structure of the cutterhead, cracking of welds, etc., and shortening downtime , The overall structure design is reasonable, the effect of avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

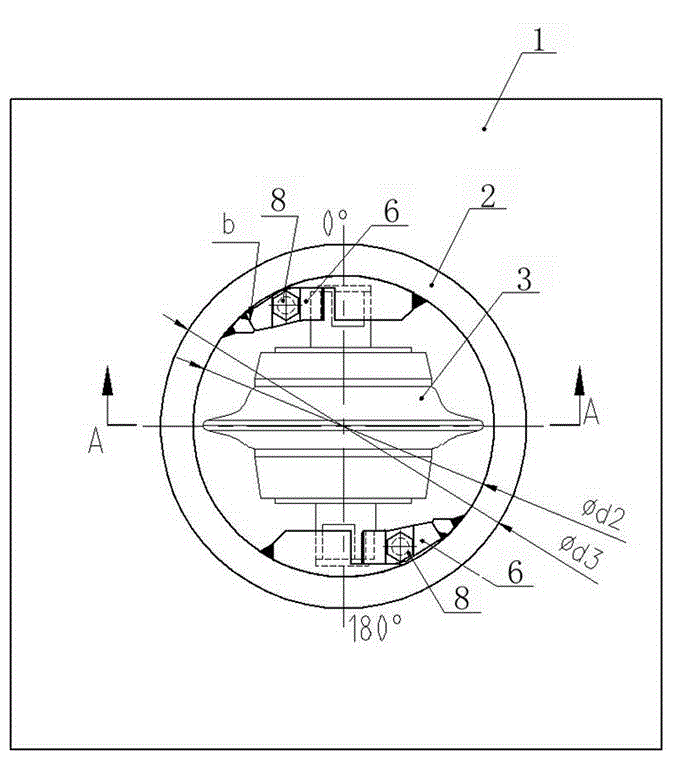

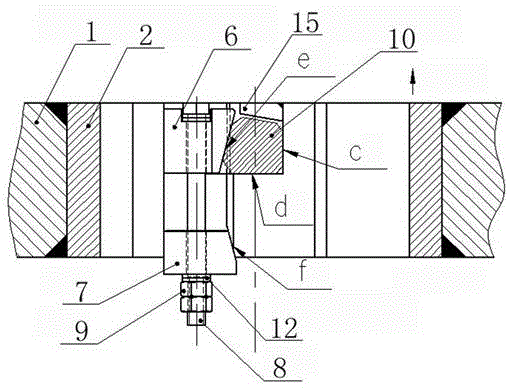

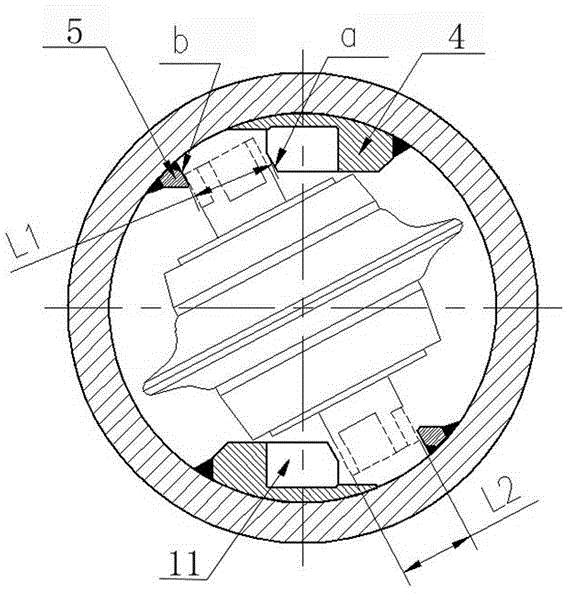

[0024] see Figure 1-Figure 4 , a circular knife box capable of bidirectionally replacing disc-shaped hobs, including a cylindrical ring-shaped knife box body fixed on the cutter head and two center-symmetric rollers arranged inside the knife box body. The cutter shaft fastening unit, the hob shaft fastening unit includes a load-bearing guide bar fixed on the inner wall of the knife box box, a limiter fixed on the inner wall of the knife box box and correspondingly set at a certain angle with the load-bearing guide bar Position guide bar, and wedge-shaped compression block, wedge-shaped tension block, tension bolt, lock washer and two nuts that are matched between the load guide bar and the limit guide bar, the load guide bar faces the limit One side of the guide bar is provided with a stepped bearing platform, the hob shaft is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com