Reciprocating piston mechanism engine

A technology of reciprocating piston and piston mechanism, which is applied in the open gas positive displacement engine factory and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

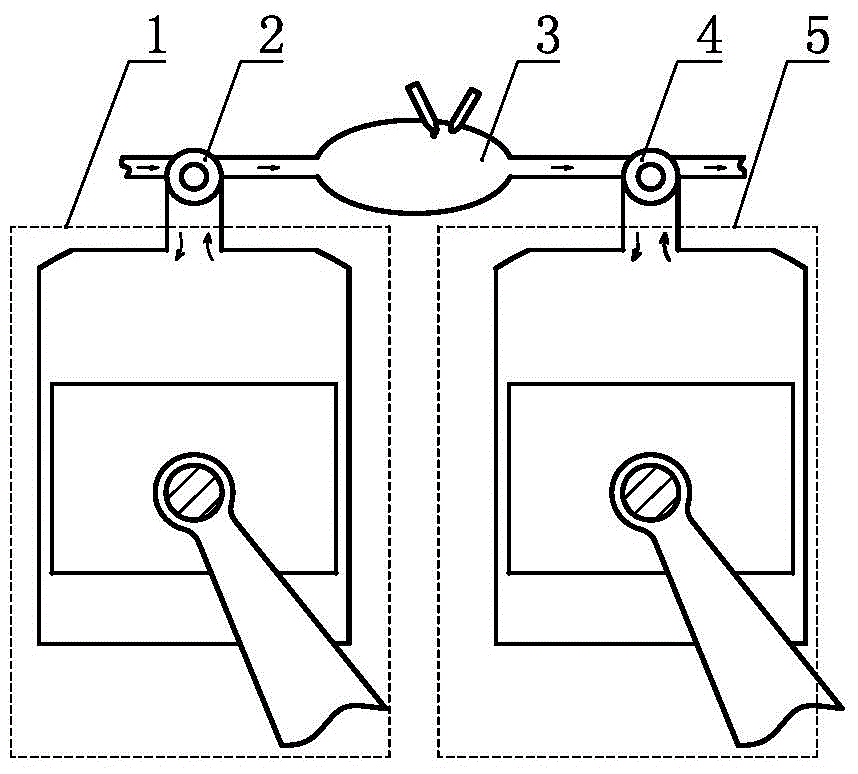

[0045] A reciprocating piston mechanism engine, such as figure 1 As shown, it includes a reciprocating cylinder-piston mechanism 1 for compression, a gas compression rotary control valve 2, a continuous working medium heater 3, a gas expansion rotary control valve 4, and a reciprocating cylinder-piston mechanism 5 for expansion. The gas compression rotary control valve 2 and The reciprocating cylinder-piston mechanism 1 for compression is correspondingly arranged to form a part of the reciprocating piston rotary valve compression unit, and the gas expansion rotary control valve 4 is correspondingly arranged to form a part of the reciprocating piston rotary valve expansion unit with the reciprocating cylinder-piston mechanism 5 for expansion. , the working medium outlet of the reciprocating piston rotary valve compression unit communicates with the working medium inlet of the reciprocating piston rotary valve expansion unit through the working medium continuous heater 3, and the...

Embodiment 2

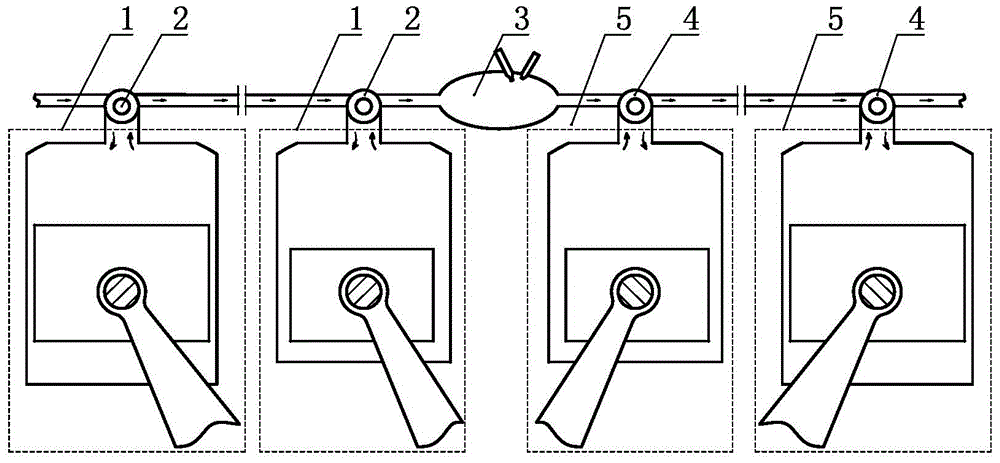

[0050] A reciprocating piston mechanism engine, such as figure 2 As shown, on the basis of Embodiment 1, there are more than two reciprocating piston rotary valve compression units with different displacements, and all the reciprocating piston rotary valve compression units are connected in sequence from large to small in displacement. All the reciprocating piston rotary valve compression units are connected in descending order of displacement, and the working medium outlet of the reciprocating piston rotary valve compression unit with the smallest displacement is connected with the continuous working medium heater 3 . Preferably, there are more than two reciprocating piston rotary valve expansion units with different displacements, all the reciprocating piston rotary valve expansion units are connected in sequence from small to large displacement, and the reciprocating piston rotary valve with the smallest displacement The working fluid inlet of the expansion unit communicat...

Embodiment 3

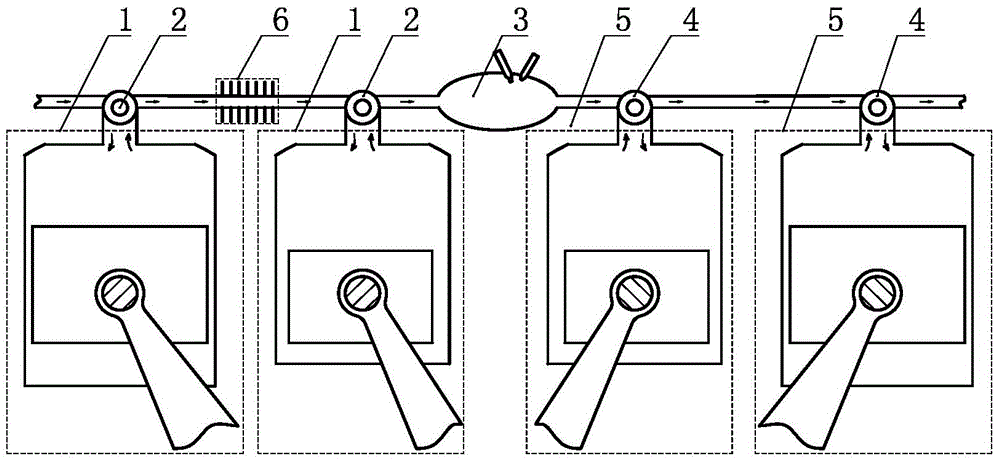

[0053] A reciprocating piston mechanism engine, such as image 3 As shown, on the basis of Embodiment 2, a cooler 6 is arranged in series between at least two adjacent reciprocating piston rotary valve compression units.

[0054] As a changeable implementation manner, embodiment 1 and embodiment 2 and their changeable implementation manners can further have a cooler 6 arranged in series between at least two adjacent reciprocating piston rotary valve compression units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com