Refrigerator and control method used for cooling draught fan of refrigerator compressor

A heat dissipation fan and control method technology, which is applied in the direction of household refrigeration devices, applications, refrigerators, etc., can solve the problems of reducing speed, energy saving and noise reduction, and achieve the effect of ensuring heat dissipation, good heat dissipation, and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

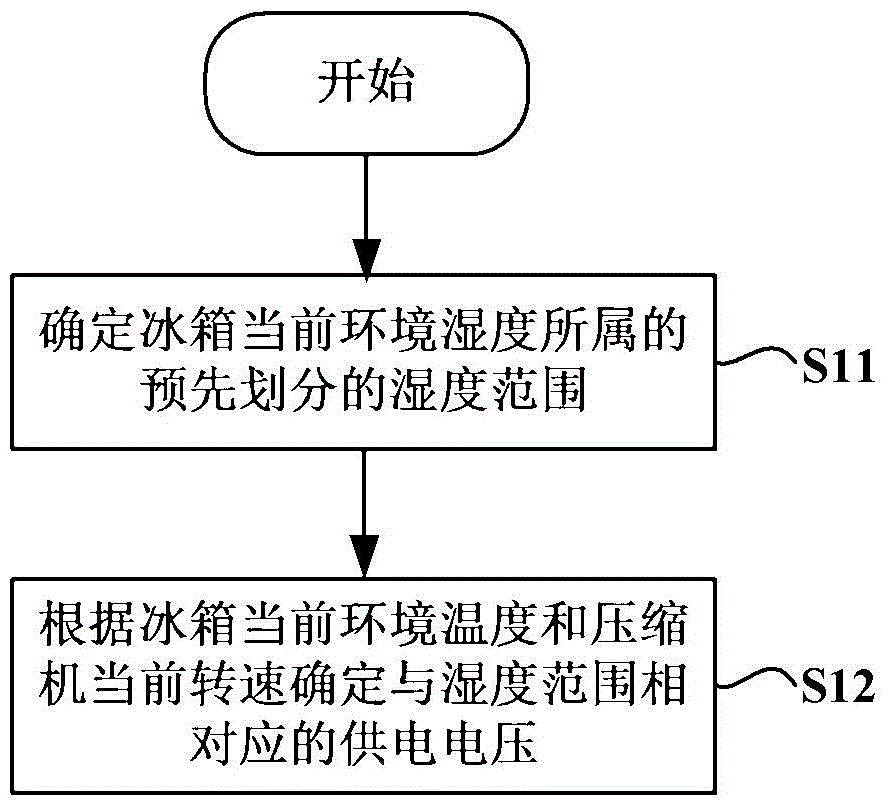

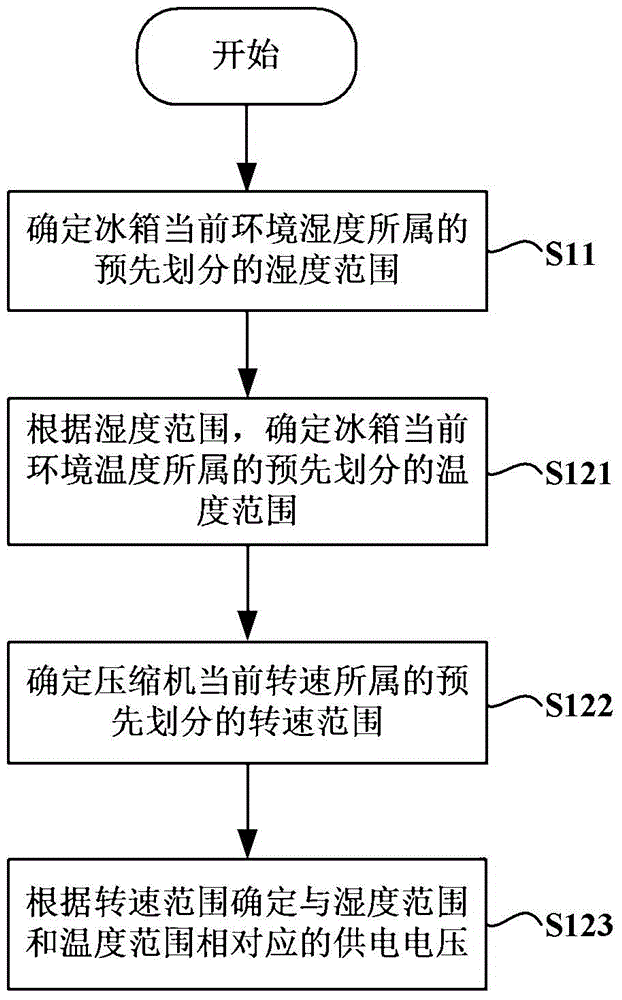

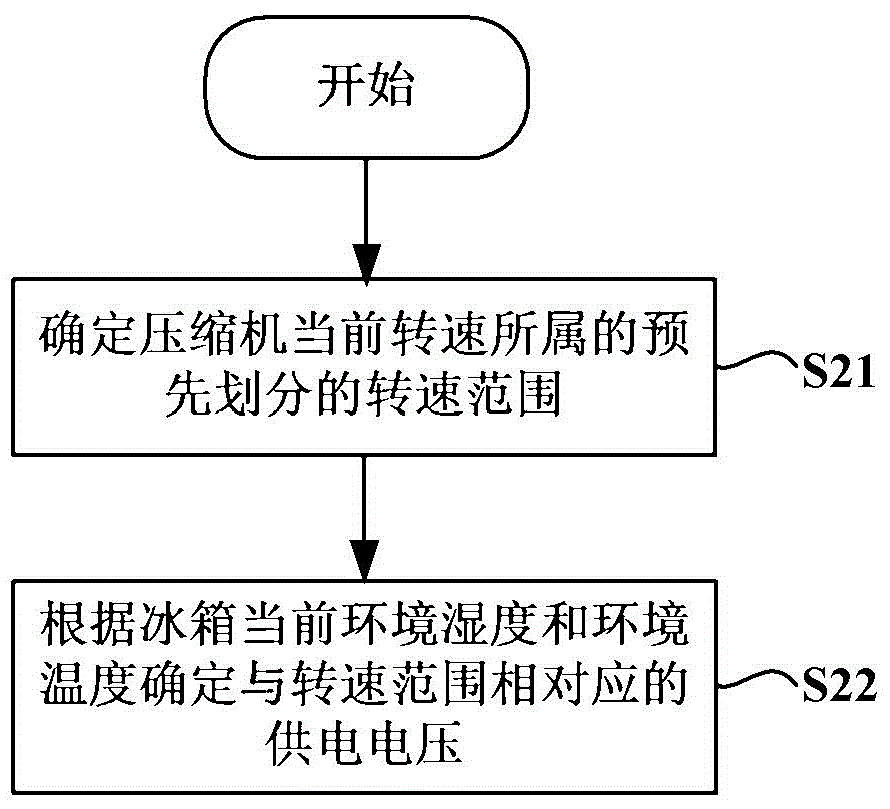

[0063] The inventors of the present application have found that the ambient humidity has a certain influence on the heat dissipation rate; the inventors of the present application have further found that when the humidity is high, the heat dissipation rate is slow and requires a high fan speed; when the humidity is low , the heat dissipation rate is faster, and a lower fan speed is required. Therefore, in the method for controlling the cooling fan of the refrigerator compressor according to the present invention, the power supply voltage of the cooling fan is determined according to the current ambient humidity and ambient temperature of the refrigerator and the current rotational speed of the compressor.

[0064] According to the method for controlling the heat dissipation fan of the refrigerator compressor according to the embodiment of the present invention, the power supply voltage or the rotational speed of the heat dissipation fan can be controlled according to the curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com