Hydraulic system of amphibious vehicle

A hydraulic system and amphibious technology, applied in the field of hydraulic systems, can solve the problems of crawler drive wheel system structure, complex working principle, and poor fast-moving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

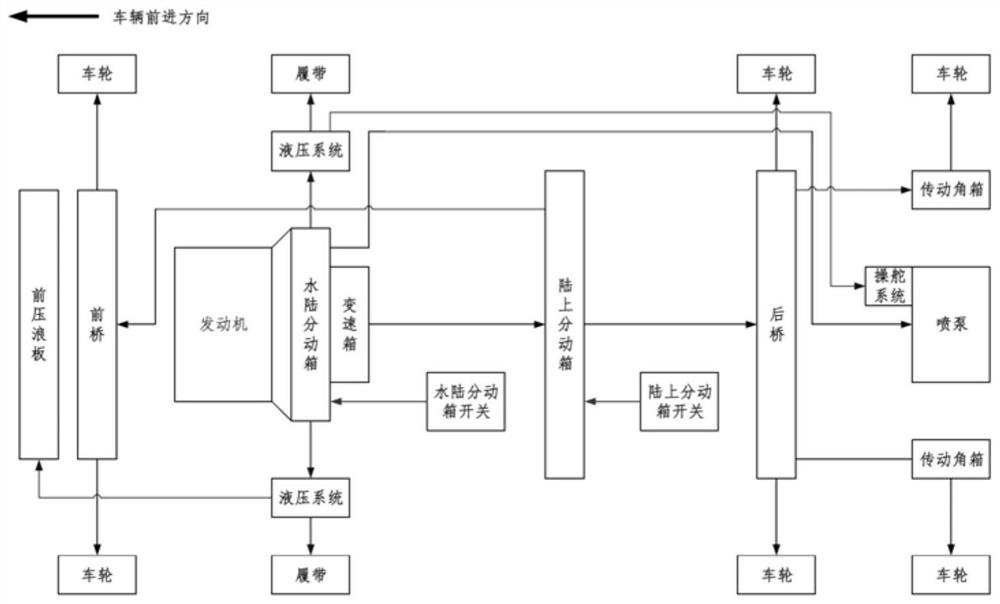

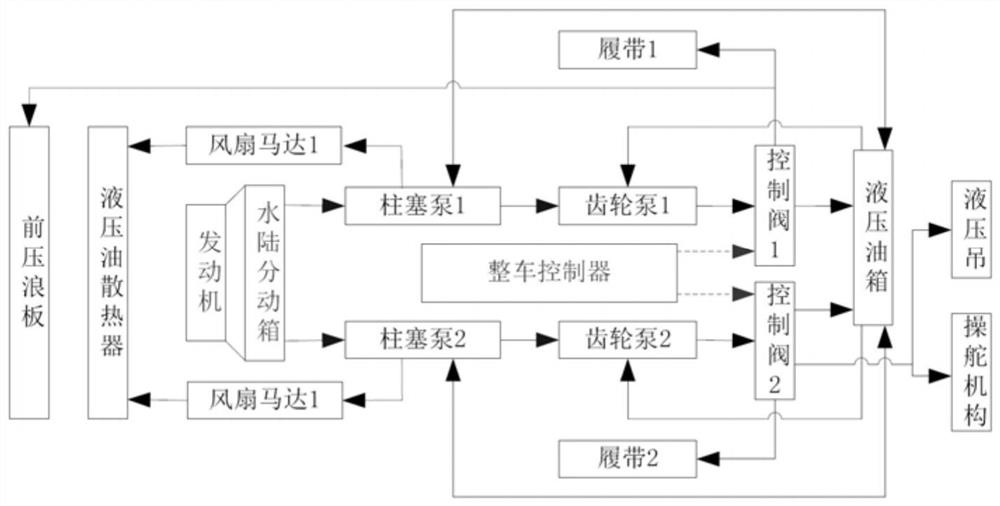

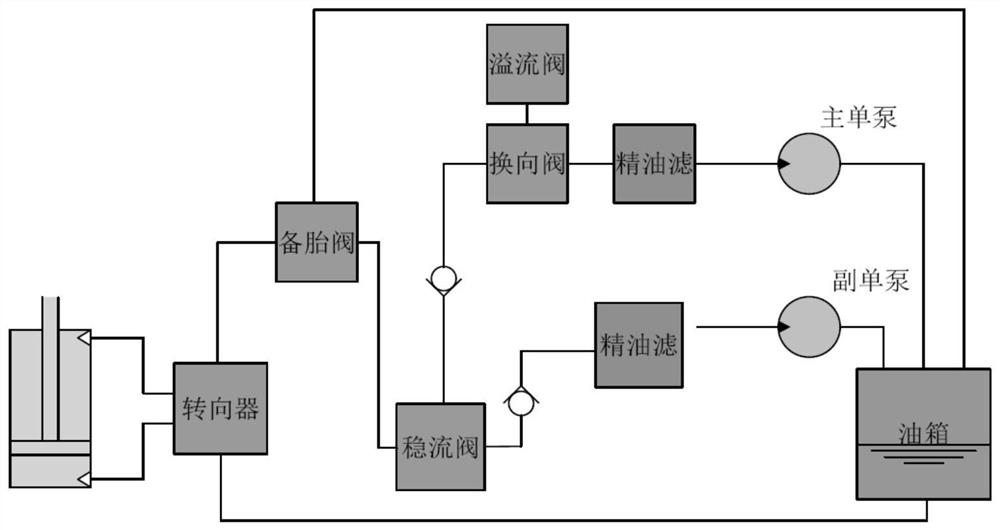

[0017] The new wheel-track compound amphibious vehicle has added a crawler walking mechanism, which is used to increase the force bearing surface and power in environments such as waterway junctions, thereby increasing the rapid maneuverability in some special environments. For this purpose, the hydraulic pressure of the whole vehicle is designed. The control system is used to realize the hydraulic drive control track, specifically as figure 1 , 2 As shown, the power output of the engine transmits kinetic energy to the crawler hydraulic system through the amphibious transfer case, and then the crawler hydraulic system drives the rotation control of the crawler and so on. The engine provides kinetic energy to the jet pump through the amphibious transfer case to provide power for driving on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com