Magnetic sensing device and preparation process thereof

A preparation process and magnetic sensing technology, which is applied in the direction of the size/direction of the magnetic field, can solve the problems of sensitivity and precision to be further improved, poor sensing performance of the device, etc., and achieve the effect of improving the sensing ability and sensitivity, and increasing the sensing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

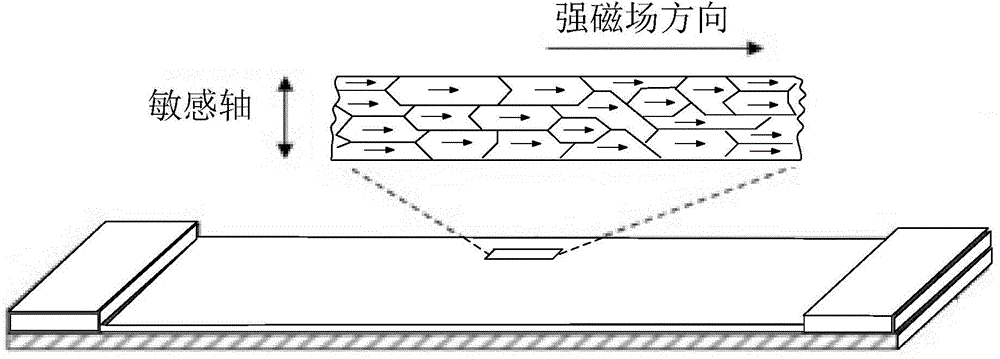

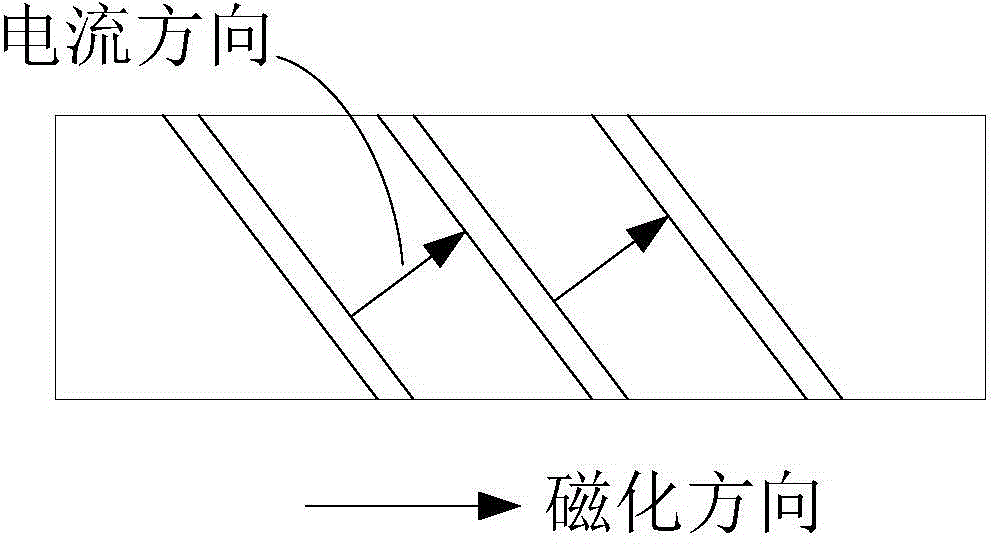

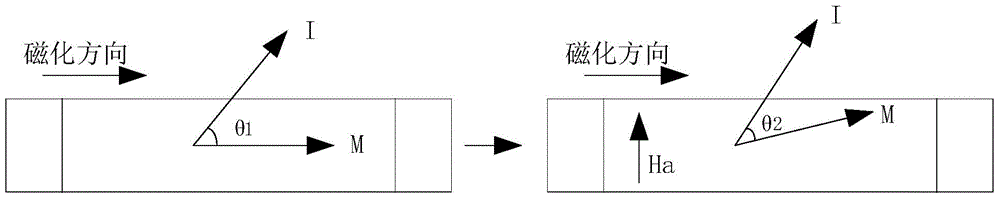

[0068] see Figure 8 , the present invention discloses a magnetic sensing device, which includes a third-directional magnetic sensing component (Z-axis sensor), and the third-directional magnetic sensing component includes: a substrate 1, a magnetic conduction unit, and an induction unit. A groove 2 is opened on the surface of the base 1, and the main part of the magnetic conduction unit is arranged in the groove 2.

[0069] Specifically, the magnetically permeable unit includes a first magnetically permeable subunit 41 and a second magnetically permeable subunit 42. The main part of the first magnetically permeable subunit 41 is arranged in the groove 2, and a part of the groove 2 is exposed to the The surface of the substrate 1 ; the main part of the second magnetically permeable subunit 42 is disposed in the groove 2 , and a first dielectric material is arranged between the second magnetically permeable subunit 42 and the first magnetically permeable subunit 41 . The magne...

Embodiment 2

[0092] The difference between this embodiment and Embodiment 1 is that in this embodiment, the magnetically permeable unit includes several magnetically permeable subunits (such as more than 3), and the first magnetically permeable subunit and the second magnetically permeable subunit serve as Two of the permeable sub-units. The main part of each magnetic permeable sub-unit is arranged in the groove, and the included angle between the main part of the magnetic permeable sub-unit and the base plane is 45°-90°; each magnetic permeable sub-unit is separated by a dielectric material.

[0093] The number of induction sub-units in the induction unit is the same as the number of magnetic conduction sub-units. Each magnetic permeable subunit senses a magnetic signal in the third direction, and outputs the magnetic signal to the corresponding inductive subunit for measurement; each inductive subunit measures the magnetic field in the first direction or / and the second direction, and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com