Self-adaptive prediction method for running temperature of power battery

A self-adaptive prediction and power battery technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of inconvenient use and unfavorable power battery temperature prediction, and achieve accurate temperature prediction results and simple methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

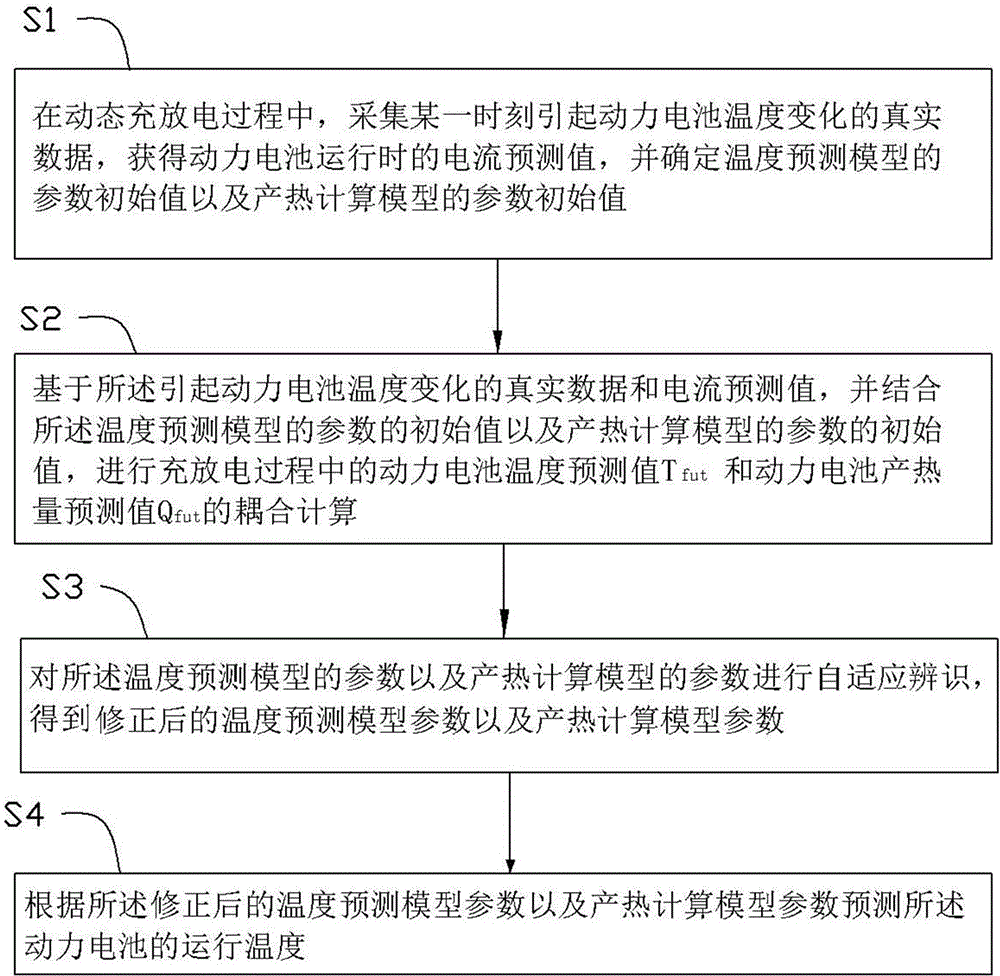

[0013] see figure 1 , an embodiment of the present invention provides an adaptive prediction method for the operating temperature of a power battery, which includes the following steps:

[0014] S1: During the dynamic charge and discharge process of the power battery, collect the real data that causes the temperature change of the power battery at a certain moment, estimate the current prediction value of the power battery during operation, and determine the initial value of the parameters of the temperature prediction model and the heat generation calculation model. parameter initial value;

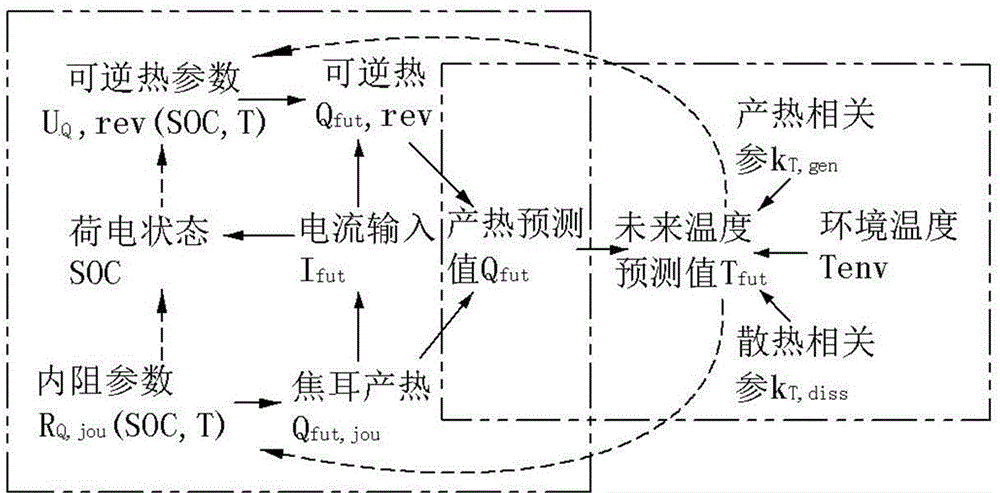

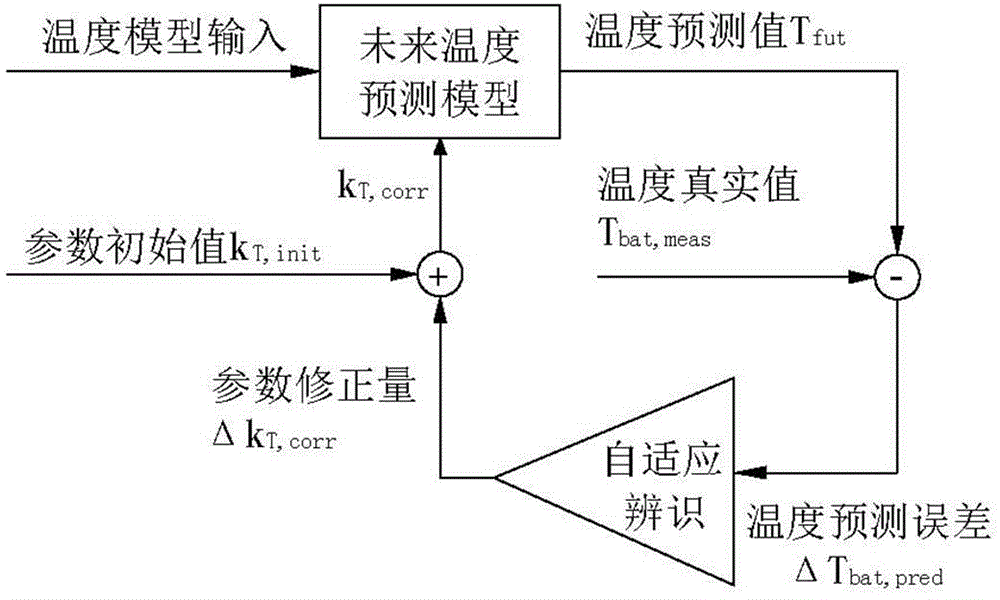

[0015] S2: Based on the real data and current prediction value that cause the temperature change of the power battery, combined with the initial value of the parameters of the temperature prediction model and the initial value of the parameters of the heat generation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com